Are you unintentionally creating a cycle of failure by failing to classify and track work properly? Understanding the distinction between proactive and reactive work can transform your maintenance strategy from constant crisis to consistent control.

Einstein once said there are three rules of work: “Out of clutter, find simplicity. From discord, find harmony. In the middle of difficulty lies opportunity.” Those rules seem quite applicable in today’s reliability arena.

Work is an honorable pursuit that does not include working for work’s sake. Work should be efficient, effective, and, above all, meaningful. In my 30+ years of performing Maintenance Operation Effectiveness Reviews (MOERs) and examining and studying maintenance performance across all disciplines and industry types, I’ve found that between 30% and 70% of such work is unnecessary.

This is due, in part, to legacy PMs that are no longer relevant, are not objectively written, are ineffectively scheduled, or are not completed, thereby causing premature asset failures that require additional corrective, reparation, and restoration work.

In many cases, this becomes a repetitive cycle stemming from a lack of work tracking, classification, reporting, and, importantly, understanding good versus poor work practice and management.

The Word ‘Understanding’ Is Key

To understand work practices and recognize opportunities for change, maintenance must analyze historical work data to determine the ineffectiveness of its current planning and scheduling methods. Unfortunately, many work-management systems aren’t set up to allow ready access to and mining of collected data and, in turn, to reflect that data through timely, meaningful performance reports.

What differentiates a work management system, commonly referred to as a Computerized Maintenance Management System (CMMS) or Enterprise Asset Management (EAM) system, from a simple work order system is its ability to access, collate, sort, and filter data in accordance with the end user’s defined needs. Simply put, it allows an end user to convert historical data into meaningful reporting information for decision-making purposes.

All asset management systems can set up “Code” tables that interact with the work order, allowing users to definitively collate and filter work order data about pre-specified code labels.

Setting Up Your System to Better Understand Work

One of the most effective ways of understanding work is to code the performed type. This is achieved using the code tables named Type/Sub-Type, Category/Sub-Category, or Classification/Sub-classification. If no coding tables are readily available, the system’s software provider can often offer these tables as a customization.

The primary sort table helps us understand the type of daily issues, which is useful for facilitating work request flow, Planner work loading, trade group work loading, and staffing levels.

Typical primary work-type sort codes may include:

- Electrical (Machine/Building/Vehicle)

- Electronic (Machine/Building/Vehicle)

- Mechanical (Machine/Vehicle)

- Structural (Building)

- Plumbing (Machine/Building)

- HVAC (Building/Vehicle)

- Carpentry (Building).

The secondary work-type code is used to code the work order itself. The work-order type groups the type of work performed and allows maintenance to determine the relationship and effectiveness of proactive versus reactive work and planned versus unplanned work.

Performing work in a reactive environment is 2 to 5 times more costly than performing work in a proactive environment.

The proactive work environment fosters strategies and management practices, resulting in more effective resource management and reduced work backlogs.

Proactive Work. Preventive, Predictive, Condition-Based, and Planned Run-to-Fail are all proactive work strategies. Through assessment and trending for pending failure, corrective action can be planned, scheduled, and executed well before any eventual breakdown occurrence; proactive work maximizes equipment uptime.

Reactive Work. In comparison, reactive work is an unplanned, unscheduled, and often unnecessary response to equipment breakdown. To minimize loss of service caused by equipment downtime, reactive repairs are usually “quick fixes” or temporary solutions that can result in unnecessary, repetitive, premature failures.

Typical work-order-type sort codes may include:

Emergency Work Order Type

In the event of a true emergency (911) event, work is often scheduled without a work order. Once the work is complete and the emergency addressed, the work and any parts used can be captured and easily retrieved for reporting purposes when captured on an “Emergency Work Order” type. The Emergency Work Order should be the least-used type of work order.

PM – Preventive Work Order Type

A PM Work order can be issued against any physical asset that has consequences for its failure, specifically:

- Its failure will cause a safety issue.

- Its failure will cause a loss of service.

- Its failure will cause an environmental loss.

- Its failure will result in high replacement or repair costs.

A PM Work order can be issued for any calibrated device (instrument, tool, scale), safety device (harness, gas analyzer, retractable lanyard, hoist), or regulated entity (pressure relief valve, crane, forklift) requiring routine calibration, certification and evidence of regulatory compliance. A PM Work order defines a routine recurring event that is planned and scheduled according to the following:

- Calendar (daily, weekly, monthly, annually, etc.)

- Meter Readings (Hours, Kilometers, Gallons / Liters, etc.)

- Condition Readings (Level, amperage, flow rate, vibration, temp, Go/No-Go state).

A typical PM job plan may include cleaning, lubrication, filter change, inspection, minor adjustments, calibrations, and equipment certifications.

PdM – Predictive Work Order Type

A “PdM Work Order” can be issued against any physical asset and is used to augment the PM program. PdM Work is non-intrusive work that allows the maintainer to inspect assets using various diagnostic tools that can tangibly capture trending data to establish an equipment signature baseline and track baseline deviations to determine if the asset’s condition is deteriorating and at what rate.

This information is then used to predict failure so that a suitable proactive maintenance reparation approach can be exercised in advance of a failure occurrence.

A PdM Work Order can define a single event or routine recurring event that is planned and scheduled according to:

- Calendar (daily, weekly, monthly, annually, etc.)

- Meter Readings (Hours, Kilometers, Gallons / Liters, etc.)

- Condition Readings (Level, Cleanliness, etc.).

The majority of PdM work includes diagnostic checks, verifications, and a typical PdM job plan may employ the use of the following diagnostic methods:

- Air balancing

- Amperage testing

- Infrared Thermography

- Flow metering

- Laser alignment

- Oil analysis

- Ultrasonic (acoustic) testing

- Vibration Analysis

- Corona discharge testing

Investigative Work Order Type

An “Investigative Work Order” is created when the work-request job scope is unclear and needs further clarification/information to plan or complete the job. Investigative Work Orders are issued specifically to troubleshoot equipment when the problem is unknown. The investigative Work Order is also used to develop a scope of work for planning and scheduling purposes when the planner cannot personally view the equipment problem.

Corrective Work Order Type

A “Corrective Work Order” is created directly from work found and recommended on completed PM and PdM Work Orders. Corrective Work Orders are fully job-planned and include labor and material requirements. This type of work order is used to analyze PM effectiveness, assess PM-frequency adjustment requirements, and develop the evolution of PM scope.

Repair Work Order Type

A “Repair Work Order” is created to cover planned equipment repair/redesign/upgrade events in which equipment downtime is scheduled. Repair Work Orders are issued specifically to cover:

- Work resulting from impaired or reduced equipment performance and design specification

- Work resulting from Investigative Work order recommendations

Service Work Order Type

A “Service Work Order” reflects planned work to perform basic services for the client. Such work can include picture hanging, furniture moving, room cleanup, and installation and removal of seasonal decorations, among other things.

Breakdown Work Order Type

A “Breakdown Work Order” is a genuinely reactive work order. It’s used when an asset has failed and is no longer functioning. The Breakdown Work Order is the second-least desirable work order type after the Emergency Work Order type.

Shutdown Work Order Type

A “Shutdown Work Order” is issued for planned work on assets that are taken out of commission for a short period so that multiple repairs can be performed at the same time repairs. Shutdown work is planned and scheduled well in advance of the event.

Training Work Order Type

A “Training Work Order” is a planned-work order used to track time spent on training activities by a maintainer. This is useful when the trade timesheet is linked directly to work order time charges.

Contractor Assistance Work Order Type

A “Contractor Assistance Work Order” is a planned work order used to track internal resource time allocated to assist or supervise (oversee) contractors so that a true contractor cost can be calculated.

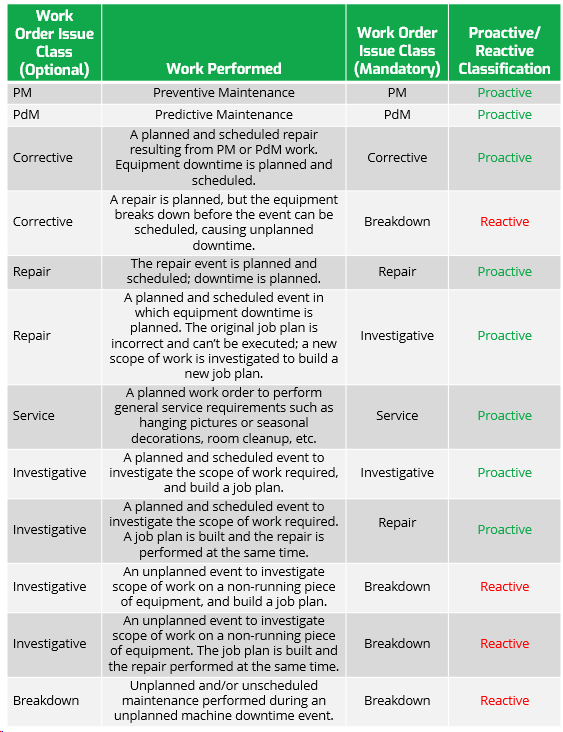

Note that most software will allow you to change the WO type before closing. If this option is exercised (highly recommended), reporting should be done using the more accurate closing WO type. Table 1 (below) shows how work data can be collated to calculate and understand proactive-to-reactive work ratios.

Table 1. Understanding Proactive versus Reactive Work Using Work Order Type Codes

Finally, if the trade designation and maintainer name or badge number are also field-assigned on the work order, these details can be used as additional data filters to develop powerful work-associated report filters to understand the work performed, its impact, and how work is distributed and managed across the maintenance organization—all from a few simple, easy-to-use codes.

Originally published in The RAM Review.