Any planning and scheduling system should eliminate delays in the maintenance process and coordinate the maintenance resources and production schedule. However, not all jobs are good candidates for planning.

Very simple jobs usually do not go through the planning process, as little value is added. Additionally, jobs with low predictability are not good candidates since a planner cannot accurately predict the job’s resources and part needs.

The Importance of Planning and Scheduling in Maintenance

Every organization involved in a planning and scheduling effort should identify the jobs that should not be planned. However, all jobs are good candidates for scheduling as long as a reasonable time estimate can be made.

Every organization involved in a planning and scheduling effort should identify the jobs that should not be planned (for example, changing light bulbs or emergency work). However, all jobs are good candidates for scheduling as long as a reasonable time estimate can be made.

As far as planning and scheduling is concerned, work is either urgent or nonurgent. This sounds simple enough: Urgent work must be attended to without delay, whereas non-urgent work allows taking the time required to plan and schedule it if tremendous savings can be created, and that is the ultimate goal of planning and scheduling.

Urgent work is fraught with delays, misdirection, and confusion. Still, by its very nature, we cannot take the time to investigate the job’s needs, estimate the resources, develop a plan, and obtain the necessary parts. Instead, we run headlong into the fray and figure out what we need as we go. Sometimes, we have to back up and try a different route.

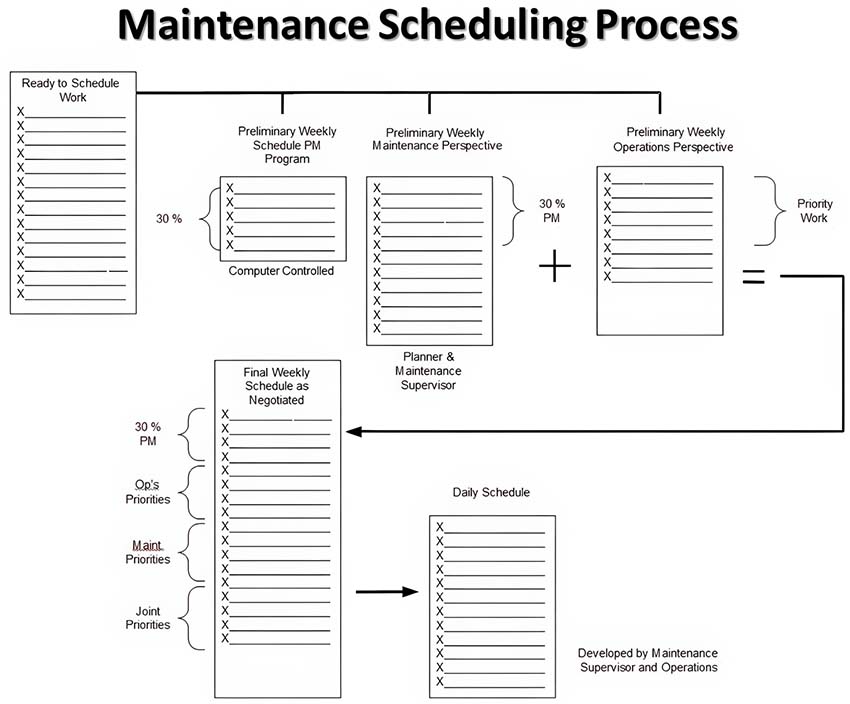

The Maintenance Scheduling Process: A Proven Model

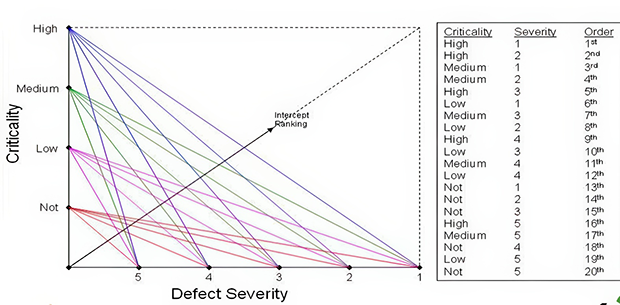

The Maintenance Scheduling Process is simple if you follow the ” Intercept Ranking Model” – Scheduling work orders based on Asset Criticality and Defect (how long before it fails) Severity.

Is Your Maintenance Scheduling Aligned with Best Practices?

Assess if your Maintenance Planning and Scheduling aligns with known Best Practices.

- Is someone responsible for scheduling either a full-time maintenance scheduler or a full-time planner/scheduler?

- Do planners/schedulers or schedulers work closely with production to schedule maintenance work?

- Is maintenance work scheduled one week ahead at least?

- Is maintenance work scheduled by day by hour?

- Is maintenance work scheduled with a maintenance person’s name assigned?

- On significant outages, do maintenance personnel provide input into the schedule?

- Does the scheduler or planner/scheduler facilitate the maintenance scheduling meeting?

- Does the scheduler or planner/scheduler not report to maintenance supervision? Reporting to a maintenance manager is acceptable.

- Is next week’s schedule posted at least the prior Friday for all to view, including maintenance and production?

- Is schedule compliance above 80%?

Total “yes” answers times 10 = (possible 100 points)

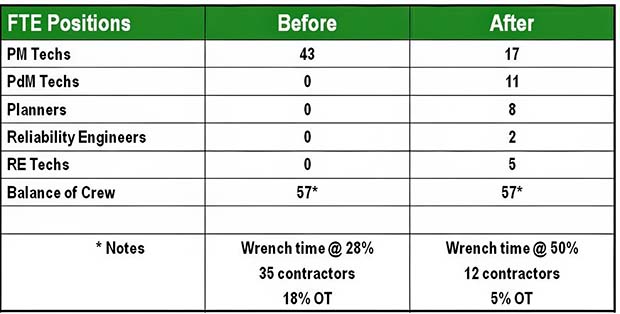

A properly designed and executed planning and scheduling system can be the most effective means of increasing Maintenance Wrench-Time (hands-on tool time)

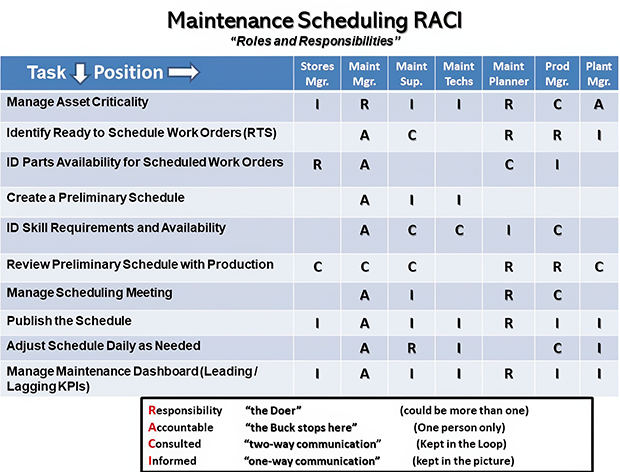

Defining Roles and Responsibilities in Maintenance Scheduling

Defining roles and responsibilities in the maintenance scheduling is critical to ensure everyone is aligned.

How to Create a RACI Chart for Maintenance Scheduling

1. Have a simple process map of the process to use as a guide

2. Invite all stakeholders in this process, i.e. Production manager, maintenance supervisor, maintenance planner, stores manager, safety, reliability engineering

3. Focus on the process map and identify each person’s role.

R – Responsible (the doer – could be multiple positions)

A – Accountable (the buck stops here – one person only)

C – Consulted (two-way communication)

I – Informed (one-way communication – no reply expected nor accepted)

4. Focus all scheduling meetings around the subject on the RACI – patience is required

5. After achieving success, move to the next process using these steps.