Raise your hand if you want to go from reactive to proactive maintenance. Going from reactive to proactive is like the shiny red bike in the toy store window before Christmas. All the kids going by want one, but only a few of those kids’ parents will spring for one. Proactive maintenance is similar-all the maintenance professionals wish to have it in their plant, but few companies’ management will step up to the plate and pay.

After all, the usual way to do proactive maintenance is an arduous, multi-year journey that requires money (sometimes a good deal) and top management support.

There has got to be a better way. If you believe what you read, it only takes a sound, solid PM/PdM system. There is a logical problem with this method unless you get extra and specific resources for the duration of the effort. Let’s look at that. The PM program will bring you to proactive maintenance, but without additional resources, you’ll need a very thick skin, a great deal of patience, and a decade’s attention span.

A PM program can move you toward proactive maintenance, but without extra resources, you’ll need a decade’s patience and a very thick skin.

To see why this is so, let’s look at reactive maintenance. What does it mean to be running a reactive maintenance effort? If we could look at the condition of the equipment, we would find that most have suffered deterioration.

Most of the equipment is in various states of impending catastrophic failure. There is also no effective effort to identify deterioration that will lead to failures and prioritize and deal with it before the machine breaks down.

The Pitfalls of Bootstrapping a PM Program

If that is the state of a reactive shop, why not use a PM system to turn the ship around? What is this logical problem mentioned earlier? Let’s assume reasonably level resources for maintenance.

Everyone is already working on breakdowns (most of the time). Who will do the additional PM workload (the corrective items found by the PM (and other) inspections? Well, the PM is usually done when there is nothing else to do. This tactic is called “bootstrapping” the PM system.

Bootstrapping might have worked when your personnel weren’t already stretched so thin. It never worked that well because of PM’s logic. Half of the effectiveness of PM comes from basic maintenance tasks like cleaning, lubricating, and tightening bolts. This activity lengthens the life of equipment that is already in good shape (no critical deterioration to cause breakdown).

The other half of the key to PM’s effectiveness in reducing breakdowns is that when inspectors find deterioration, it is fixed before it turns into a breakdown (called corrective maintenance).

Bootstrapping a PM program without extra labor is like patching a sinking ship—eventually, it will still go under.

Visualize that your shop is stretched thin from cutbacks, and you add PM activity. Now, add additional corrective activity. What do you think will happen? Will you have the discipline to work on the equipment with corrective maintenance work identified that might fail versus equipment that has already failed? Remember, there are no extra resources.

This explains the contradiction of trying to put in PM without extra resources. Since PM has demonstrated that it takes a year or more to take effect (when done fully and correctly), many more installations are abandoned during this first year and then succeed.

This logical problem is why most PM attempts to move from reactive to proactive maintenance fail (usually not with a bang but with a whimper).

Why Defect Elimination and RCA Are Game Changers

What else can be done? Another strategy is to spend some time (say a year) doing two activities. This strategy requires some bootstrapping of the labor for the first few months and some limited materials. The first activity is getting better at reactive maintenance. Have crews figure out what should be done to reduce the time it takes to react and repair a breakdown.

Use the people in teams and some structured techniques to capture ideas and propose experiments. More on the specific methods later, but consider Root Cause Analysis (RCA) and Defect Elimination to reduce the time it takes to make the move.

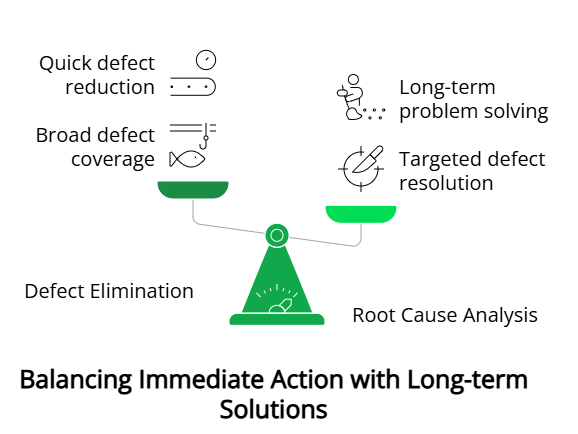

RCA and Defect Elimination treat the same symptoms (a defect) differently. Defect Elimination is like an indiscriminate shotgun approach. It treats any defects that fall into its net, whether or not they are critical. RCA is like a laser-sighted rifle. It is a precision technique. Both are needed.

Defect Elimination is a shotgun, RCA is a laser-sighted rifle—both are needed to fix failures for good.

Start tomorrow with a limited Defect Elimination program. Limit hours to 1% of gross (a 10-worker department will only get 4 hours a week for Defect Elimination. It alone will reduce your defect pool by 50% over 3 years.

RCA is reserved for repetitive events. One place to start RCA is in your repetitive failures. Using established RCA techniques, try to fix them forever. Not all the repetitive failures will be solvable with your teams and within your limited budget.

But if you picked well, these would free up some time to start more RCA projects. As a year goes on, maybe 20-30% of the repetitive failures can be resolved through RCA. As these problems get fixed forever, their labor is freed up.

Building a Sustainable Path to Proactive Maintenance

Use the time to start a PM program. Start the program small. Be sure you rigorously install PM. Start with the most critical machines. Go over any machine destined for PM and fix everything your inspection turns up before letting it become an asset in the PM system. One by one, add assets to the PM list. Now, that is the way to bootstrap a PM system.

So we reduce defects, and we target failures that suck up time. We install a PM system that preserves the gains already made. We keep our shoulder to the grindstone for a good while. Gradually, you’ll realize you are not working hand-to-mouth and that the whole place looks better. Not to bum you out, after all this work, you are never done.

That is the little secret of going from reactive to proactive by your bootstraps!

RCA: The Precision Tool for Fixing Repetitive Failures

What is RCA? Simply put, RCA is a structured process that solves problems. It applies to everything from accidents (such as the space shuttle disasters), plant fires, and explosions to minor, localized problems. Basic RCA techniques can be taught in 2 days.

RCA is best done by small teams of people (3-6) with different backgrounds. At least someone from operations and experts in the process and maintenance should be present. Also, smart people from other parts of the company must ask the “dumb” questions that the professionals would never think to ask.

The first step is to figure out what the problem is. This activity is more challenging than it sounds. Some issues are concealed; some problems result from misunderstanding, misdirection (intentional and unintentional), or mishandling.

Once the problem is defined, the consequences are spelled out, and most importantly, measures are chosen. The second big step is gathering data and brainstorming causes. You will develop a whole bunch of causes. Some are primary, and others are secondary.

All causes have causes. These causes and causes of causes form trees (called cause trees). These cause trees are checked both practically and logically. The completed set of cause trees for an event should model the event closely.

The last step is looking for an intervention to stop the chain of events that caused the failure or accident. You are trying to interrupt the cause tree. Once you have a likely story, you can test it to see if it interrupts the tree in the real world.

Then, look closely to see if there are any unintended consequences. As part of the last step, we have to make the change stick by rewriting SOPs, changing parts procured, communicating with everyone, and adding the change to drawings, CMMS tasks, or wherever will make it happen and keep it happening.