“Don’t chase 100% OEE—optimize OEE to maximize profit.”

That’s a mantra I’ve repeated in many conference keynotes, and it bears repeating now as more organizations fall into the trap of worshipping OEE as an end rather than treating it as a means. The goal isn’t perfect efficiency—it’s profitable, sustainable, and reliable operations.

Let’s start with what OEE really is:

![]()

It’s intended to evaluate our production relative to a theoretical perfect state. Typically expressed as a percentage, OEE’s value can’t exceed 100% – in theory.

Each factor in that formula holds nuance that too often goes unexamined.

Availability: Account for the True Time Budget

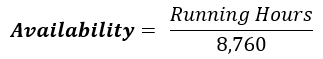

Availability is the ratio of actual running hours to the total time in a year:

If you want to go deeper, you can break it down further into minutes (525,600 per year). But the key is this: planned downtime counts as waste—it might be necessary waste, but it’s still an opportunity for improvement. Planned maintenance, operations downtime, cleanouts—these are all expected, but should be minimized and aligned with production strategy.

As I’ve said in past writings, “waste isn’t evil—but tolerating it unexamined is.”

The Deviation-Based Rate Hack

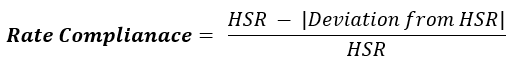

We need to move past theoretical max rates and adopt what I call the Highest Sustainable Rate (HSR). Then, calculate Rate Compliance like this:

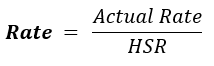

Here’s why it matters. Most practitioners calculate rate as:

While straightforward, this method allows OEE to exceed 100% if the equipment is run harder than the HSR, creating a false illusion of world-class performance. This is more than just a rounding error—it’s a fundamental flaw in logic. Running above HSR can degrade equipment, cause quality losses, and create unsustainable expectations.

By applying the absolute deviation from HSR to calculate Rate Compliance, my hack penalizes overdriving equipment just as it does underperformance. This better reflects long-term reliability, profitability, and the physical realities of your asset base.

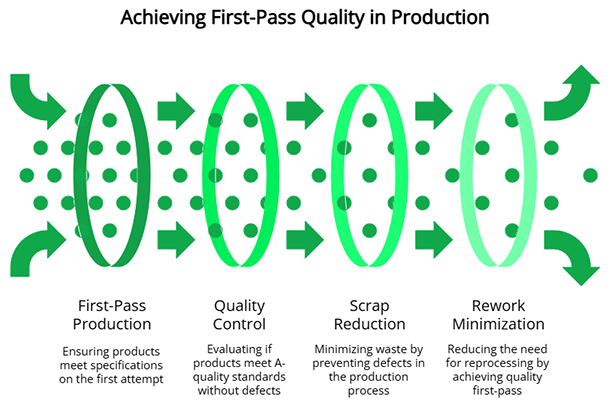

Quality: The First-Pass Test of Excellence

Quality, in the context of OEE, is defined as first-pass A-quality production – output that meets specifications the first time with no scrap, rework, or inspection-based downgrades. It’s not just about conformance; it’s about doing it right the first time. Scrap and rework not only impact cost but also tie up capacity, reduce yield, and hide upstream process deficiencies. In Lean terms, they’re clear symptoms of waste—defects and extra processing.

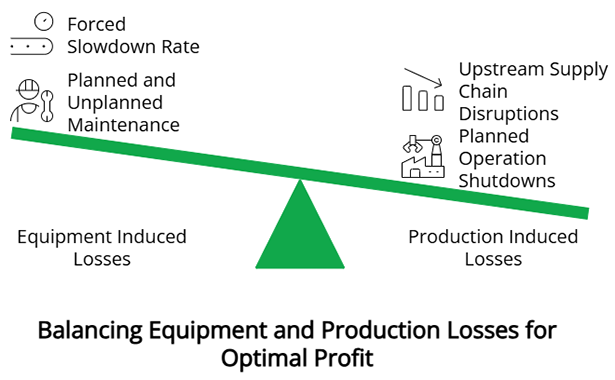

Common OEE Losses: A Profit Perspective

In a 2025 Reliable∞ article, I wrote: “OEE is a lagging indicator; use it wisely, not religiously.” That means identifying losses in the context of their impact on profit, not just OEE points. Let’s break this down:

Equipment Induced Losses:

These are physical asset-related and often within the influence of maintenance:

- Planned Maintenance – especially when it isn’t aligned to production windows.

- Unplanned Maintenance – breakdowns, emergency work, and reactive repairs.

- Forced Slowdown Rate Reduction – derating due to concerns about equipment health.

- Equipment Malfunction-Related Defects – quality issues driven by asset failure modes.

Production Induced Losses:

These originate from process design, upstream/downstream dependencies, or operations:

- Planned Operation Shutdowns – like changeovers, cleanouts, or product switches.

- Upstream Supply Chain Disruptions – feedstock shortages or delays.

- Downstream Disruptions – limited product take-away capacity.

- Planned Operation Slowdowns – due to blending, queue balancing, or test holds.

- Process-Related Defects – that aren’t necessarily linked to equipment faults.

Marketing Induced Losses:

Rarely discussed in OEE models, but vital to understanding true economic loss:

- Undersold Capacity – when the plant is ready to run, but demand isn’t there.

- Oversold Capability – pushing the system too hard to meet sales commitments, leading to long-term damage or quality shortfalls. We can’t always say yes to our customers.

“Not every loss is worth fixing,” I wrote in “Return on Net Assets (RONA)” (Reliable∞, Feb 2025). “Some inefficiencies are profit optimal.”

OEE and the Eight Deadly Wastes

OEE, when used correctly, can be a powerful lens to expose and reduce the eight classic wastes in Lean:

- Defects – Captured in the Quality component.

- Overproduction – Often masked as high utilization; can hurt availability and quality.

- Waiting – Shows up in downtime, impacts Availability.

- Transportation – Not explicitly tracked, but can influence unplanned downtime.

- Inventory – Ties up space and contributes to downstream slowdowns.

- Motion – Excessive movement can mask true rate losses.

- Extra Processing – Rework or unnecessary steps are baked into Quality loss.

- Non-Utilized Talent – When assets are misused, people are too. I think this is the “mother waste.” Solve this one and other wastes seem to resolve themselves.

When employed smartly, OEE can help teams see how operational inefficiencies stack up not just in metrics, but in real economic waste.

Strategic Use of Overall Equipment Effectiveness

As I noted in “Overall Planning Effectiveness” (Reliable∞, Jan 2025), “metrics must serve strategy, not vice versa.” OEE should inform your strategy for asset deployment, capital planning, maintenance interventions, and even sales volume commitments. But when OEE becomes the end goal, people game the system rather than improve the business.

Key Takeaways

- Target OEE sweet spots where marginal gains deliver real financial returns.

- Use the deviation-based rate hack to ensure realistic, sustainable measurement.

- Don’t over-maintain or over-automate to chase theoretical availability.

- Balance rate vs. quality to avoid hidden costs of rework or warranty claims.

- Include marketing in the equation — OEE is capped if your product doesn’t sell, or customer demands exceed production capabilities.

- Use OEE to identify the 8 wastes, but remember—removal should drive value, not vanity.

The punchline? OEE is a powerful metric when it’s grounded in profit logic. The best plants don’t aim for 100% OEE. They aim for the most profitable OEE.