You are about to install a new variable frequency drive. The supply transformer is checked for harmonic content before and after installation. The results meet IEEE 519, you are told, for the application. But do they really?

Figure 1: 13.8kV primary main immediately after the point of common connection.

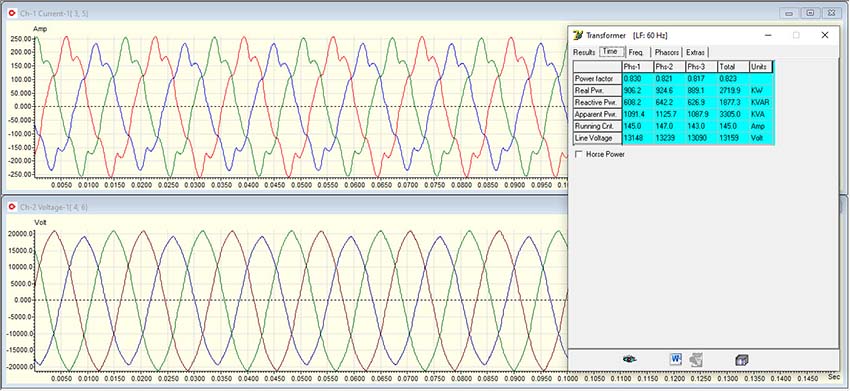

In the example above (Figure 1), we have a main transformer on the customer side of the utility meter in which the Voltage Total Harmonic Distortion (THDv) is 1.9%, and the overall Current Total Dynamic Distortion (TDDc) is 13.2%.

The limits per IEEE 519-2014 for this application are 5% overall, 3% for individual harmonics THDv, 8% overall, and 7% for 3rd through 11th TDDc. Yet most of the drives in the facility are ‘clean’ and individually appear to meet the harmonic limits outlined in IEEE 519.

IEEE 519 is the “IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems.” It is presently being updated and may, based on IEEE definitions of standards titles, have a slight title change when released.

Breaking Down IEEE 519

In summary, the scope of IEEE 519 is ‘to be used for guidance in designing power systems with nonlinear loads. The limits set are for steady-state operation and are recommended for “worst case” conditions.’

The standard is related to the limits at the point of common connection between the customer and utility. It is not meant for individual branches or systems within the customer facility.

This is important because as we move through the system when VFDs and other power electronic equipment are added to the circuit, harmonics will add, cancel, and propagate through the system.

The focus in most applications is on the THDv, leaving TDDc with the concept that current distortion ‘only affects up through the transformer’ and not other parts of the electrical system.

The standard very specifically does not cover the individual application and is meant to protect the distribution system from high harmonic conditions.

For commercial and industrial systems, some standards relate to the individual drives, such as the IEC 61800-3, “Adjustable Speed Electrical Power Drive Systems Part 3: EMC Requirements and Specific Test Methods,” for low voltage VFDs with less than a 16 Amp rating, and IEC 61000-3-12 when systems are between 16 and 75 Amps.

The statement that a VFD meets IEEE 519 is inaccurate, as your plant would meet IEEE 519.

It is important to note that there are presently utility discussions about financial penalties for sites that produce excessive harmonics into the distribution system, similar to poor power factor.

Most ‘clean drives’ focus on THDv and very little on current distortion, with a few exceptions. This is something that should be reviewed when selecting a drive.

Effects of High Current Distortion

The standard identifies the tables as the maximum and severe distortion. Each type of harmonic content has different effects and identifies different effects. These include:

- Triple Harmonics: 3rd harmonic content (i.e., 180 Hz in a 60 Hz system), which includes the 3rd, 9th, etc. These harmonics are usually caused by single-phase inverter systems such as lighting systems, PCs, chargers, and related ones. They are also recognized as adding up in neutrals and grounds.

- 5th Harmonics generally cause a counter-rotating field in electric machines (i.e., 300 Hz in a 60 Hz system). This will generate heating in rotating equipment and damage to electronics.

- 7th Harmonics generally cause a pro-rotating field in electric machines (i.e., 420 Hz in a 60 Hz system). Like the 5th harmonic plus, the higher frequency can generate resonance in capacitors, such as power factor correction capacitors.

- Even Harmonics are stationary harmonics that can occur in certain types of faults and will show up when electrical equipment such as transformers and motors are overloaded or experiencing core resonance.

- Inter-Harmonics: non-integer harmonics of line frequency, such as those identified with ESA/MCSA related to component defects and other conditions, including voltage/current notching.

- Supra-Harmonics: not included in the IEEE 519-2014 standard, but included so far as measuring in the IEC 61000-4-30. Occur in the 2- to 150 kHz range and relate to power electronics such as Variable Frequency Drives, lighting, converters, computer systems, and more. See Harmonic Overload: Impacts Of High-Frequency Switching on Modern Electrical Systems for more information. Presently, utilities are focused on grid supra-harmonics.

These all affect our electrical systems, ranging from harmonic-based power factor problems to high-order harmonics ‘blocking’ shaft brushes and blowing through most insulated bearing solutions.

While many suggest that current harmonics are not as crucial as voltage harmonics, which will damage electronics, current harmonics impact machinery very directly.

This happens to be outlined in IEEE 519 as the discussion of current distortion is a primary feature of the standard but is ignored in practice.

In the past, I’ve observed conditions in which extreme 5th harmonic conditions met IEEE 519-2014 TDDc levels in which 4500 hp synchronous motors increased starting times from 7 seconds to 14 seconds where TDDc met 7%.

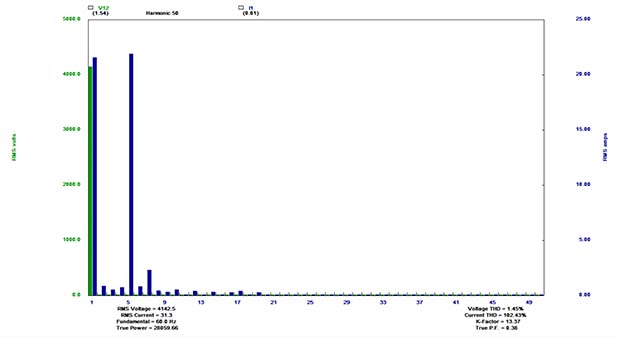

This was only acceptable because the engineering specification stated that the drive had to meet IEEE 519 values without mentioning the facility. The true power factor also dropped from 0.68 to 0.44 (Figures 2 and 3), which generated high voltage drops during equipment starting with drives in the branch circuit dropping when motors were started.

Figure 2: One phase current of three phases with heavy notching (5th harmonic) in a 4160 V system from a medium voltage drive.

Figure 3: Current harmonic distortion in orders showing high 5th harmonic and even and odd harmonics from the waveform in Figure 2.

An additional concern is that these harmonic conditions also show in neutral and ground and can be excessive (https://netaworldjournal.org/neutral-and-ground-harmonic-induced-power-losses-and-correction), resulting in dangerous conditions.

In some cases, current harmonics in ground cause ‘nuisance tripping,’ resulting in companies bypassing ground fault protection. In reality, there is no such thing as nuisance tripping, only conditions that have not been figured out or corrected.

Financial and Emissions Impacts

In the mid-1990s, before the proliferation of power electronics and a great many computerized systems, plug-in chargers, LED lighting, and other devices that generate power disturbance, the Washington State Energy Office (WSEO) for the US Department of Energy (US DOE) estimated energy losses of at least 2% related to harmonics alone.

This was in addition to all other electrical system conditions, including loose connections, phase unbalances, and power factor, adding up to a combined 2%.

In studies performed by CIGRE and EPRI, as well as other published studies, these values have increased, for power harmonics alone, to a range of 5-20% of total industrial plant energy consumption. These values will range to an additional 5-30% for ground and neutral harmonic conditions, based on field application of neutral/ground harmonic correction systems.

If we take a small 1-Megawatt (average) facility that operates 8,760 hours per year, we will have an output of 8,760 MWh. Using the USA average CO2 value for carbon inventory of 0.468 metric tonnes (mT) and $0.10/kWh and $10/kW demand, the direct energy costs (not including riders, taxes, etc.) would be $8,880,000/year and emissions of 4100mT of CO2/year.

If combined harmonic corrections are put in place assuming 10% power and 10% neutral/ground harmonics, there would be a combined 20% reduction, or a reduction to 800 kW demand, 7,008 MWh usage. This would result in a $1,776,000/year energy reduction and 1,225 mT CO2/year.

The above would be directly measurable values. Following are the ‘soft value’ improvements that would be observed over time:

- Reduction in heating of electrical components extending equipment, and even lubrication, life. This includes cables and conductors, which see skin effect increases associated with I2R losses.

- Improved overall system efficiency, including improved true power factor. True power factor cannot be improved with power factor correction capacitors and related technologies; it can only be improved by removing harmonics.

- Reduced losses through neutral conductors and related loose connections.

- Reduce capacitor failures.

- Overall improvements to system reliability due to the hidden damage from high-frequency currents.

Through the proper mitigation of harmonic content and application of IEEE 519, there are financial, reliability, and emissions impacts.

However, the IEEE 519 is applied at the point of common connection between the utility and customer (facility) and not at the applied technology, such as a VFD. When such limits are called out, the various systems add up and cause problems at the PCC.

Unfortunately, misapplication results in the mistaken idea that isolation transformers, filter systems, and related techniques can be skipped, resulting in significant problems for the facility and other companies on the related service.

The good news is that there are substantial benefits, including energy, emissions, production, and reliability improvements, that more than pay for corrective actions, which are out of the scope of this article.