Maintenance teams in many plants face tough challenges every day. They come to work not knowing what they will face because of equipment reliability issues. By executing a few new ideas, they can significantly improve the reliability and uptime of their equipment. I hope this article provides a few ideas on how to take the next step at your site.

It Isn’t What You Know That Will Kill You; It’s What You Don’t Know That Will.

An old saying is, “You cannot eat an elephant all in one bite, but you can eat it one bite at a time.” Let us begin by looking at some of the known problems that maintenance and reliability managers encounter daily:

- Breakdowns are frequent – the causes are many.

- Not enough maintenance is performed – cutbacks typically hit maintenance staff first.

Do these two problems drive you crazy? These problems, and many others, always drove me crazy when I was in maintenance management. Then, I found a few steps that made all the difference between success and failure, which is not as drastic a difference as you may think. In fact, I have learned over the years that the difference between these two outcomes is exactly as shown in Figure 1.

Figure 1: The distance between success and failure

Trust me, I have been where you are. As a former maintenance supervisor, I had to know the truth about where my program stood and develop a plan to overcome our primary obstacles so that my crew could be successful. Those obstacles were:

- Performing preventive maintenance on equipment that continues to break down.

- Planner constantly chasing parts.

- Not enough staff to complete all of the daily work.

- Completing a repair just to see it again next week.

- Production blaming maintenance for equipment problems.

Based on all I have stated, I developed a few key questions to ask myself. This took a while; I am not a fast thinker or a quick learner. However, once I resolved these questions and overcame these problems, the reliability and maintainability of our assets went up. This immediately made my life, production’s, and crew’s lives easier.

So, what are the four steps that, if followed, will greatly impact the maintainability and reliability of your equipment?

Step #1: Upgrade the Reliability and Maintainability of Your Assets

After thinking about this concept, I knew there was only one thing a maintenance person would focus on: making the equipment maintainable and thus reliable to meet the intent of the end-user production. Listed below is the process I followed to achieve this goal:

- Identify with production management (you want production to be a partner in this effort) what the most critical equipment in the worst condition is. Remember that it does not matter what we consider critical; what production management thinks is critical can deliver immediate results if it is reliable.

- Develop a plan with your crew and production to upgrade this equipment to a maintainable and reliable level.

- Identify all the problems with this equipment using all techniques and technologies available at the time, including production data on the equipment.

- Implement or ensure maintenance has a fully functional maintenance planning and scheduling role.

- Execute your plan together with production and your crew, ensuring that all repairs are made using effective, repeatable procedures with specifications and standards. Perform a quality assurance/quality control check to validate that the work was completed to specifications. All egos must be checked at the door during this time of need.

- Once all the work is complete, commission the equipment using as many predictive maintenance technologies as possible and production process data. Since a person cannot predict failure, condition-based monitoring is a much more accurate representation of what is truly being performed.

- Post a sign on the equipment that states: “WARNING: Maintained equipment in this area.” Establish an agreement between your crew and production to maintain this equipment to “like new” conditions no matter what. The results will shock you, so record the production output increase once the equipment is up and running.

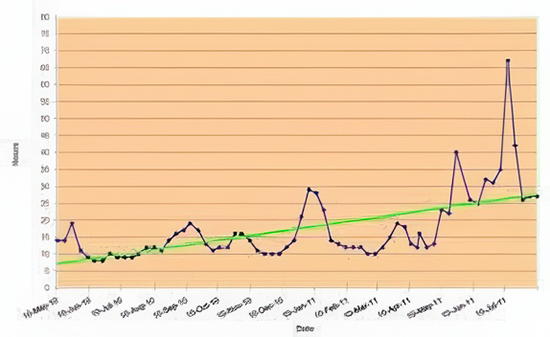

- Since people’s memories are very short, post the results that you achieve near the equipment, and make sure that they are updated daily by your production partner. One of the best items to display is the mean time between failure {MTBF) of specific “best actor” assets. Put this by the equipment every week, as shown in Figure 2 below.

- Develop an effective Failure Modes Driven Strategy for the equipment, identifying failure modes, causes of failures, etc. to build a solid maintenance plan using preventive maintenance, predictive maintenance, and condition-based monitoring.

- Based on production management’s input, move to the next piece of equipment and complete the steps the same way you did for the last one.

Figure 2: Mean time between failure (MTBF) example – 900 electric motors (compliments of Kim Hunt – Domtar)

If you follow this same process, you will successfully improve your assets’ reliability and maintainability while meeting production requirements.

Step# 2: Identify Where You Are and Where You Are Going by Using Simple Metrics That Measure EFFECTIVENESS.

The answer is to have the right effectiveness metrics and focus on continuous improvement. A great example would be if preventive maintenance (PM) compliance is above 98%, but the equipment continues to fail. It does not make sense, right?

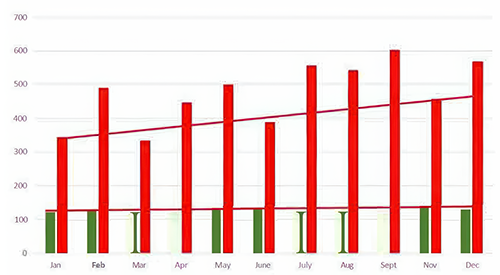

Have you ever considered using a line graph that shows the correlation between PM labor hours and emergency labor hours to measure PM effectiveness? You must know where you are before you can begin a journey.

See Figure 3, and if the results are unacceptable, you should review Step #1 again. PM compliance is a metric that only measures if PMs are completed on time. It is a joke in many organizations.

Figure 3: PM vs. emergency labor hours

With this one metric, you will know where you are with your current PM program. Once you know where you are, you can begin to develop a plan to head in the right direction.

Step #3: Use Maintenance Dashboards to Manage an Area or Function

Figure 4: Maintenance dashboard example

The next step is to develop a maintenance dashboard that has a live comparison of specific KPls which validate each other. This is like driving down the road in your car and looking at all the gauges; if one is flashing red, you may need to stop and solve the problem. The KPI dashboard concept is the same. This specific one can be fed by an Excel program, which is populated by your CMMS/EAM or other data source.

To build the dashboard, begin by identifying three questions that you would like to know the answer to on a weekly or monthly basis, which would confirm or deny all KPls are accurate.

Question 1: Are work orders closed out accurately? (Planner closes work order.)

Question 2: Is the data accurate? (Review data accuracy monthly.)

Question 3: Are my metrics improving because our actions are effective?

Step #4: Create and Manage the Plant with a “Plant Scoreboard”

Post the plant scoreboard on video monitors or charts in the plant, all production areas, and the maintenance shop.

Figure 5: Plant scoreboard example

Without a definition, you just have someone’s opinion.

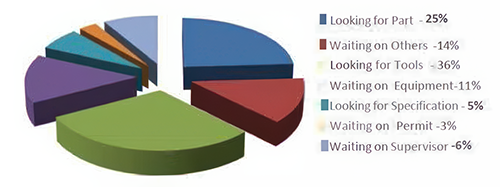

Wrench Time is “Hands-on tool time,” or the time your people are actually “turning wrenches” or performing proactive work. It is also an indicator of whether your planning and scheduling functions are meeting requirements.

Figure 6: Results from the author’s wrench time study

World-class wrench time is 55%- 65%. Note: If your wrench time is 25% and you improve it to 50%, you increase proactive work by 100%. A workforce of ten maintenance people at 25% wrench time that moves to 50% wrench time is now completing twice as much effective maintenance work with the same number of technicians.

Preventive Maintenance: Actions performed on a time- or machine-run-based schedule that detect, preclude, or mitigate degradation of a component or system to sustain or extend its useful life through controlling degradation to an acceptable level.

Planned Work: The percent of work orders with all the defined fills filled in. A planned job, at the minimum, should have:

- Repeatable, effective work procedures

- Equipment specifications and standards

- Required parts and potential parts

- Coordination required and with whom and when

- Warnings and cautions

- Craft and estimated labor hours

- Actual prep and execution time

Planned Work Objective: A repeatable/effective PM, repair, rebuild, lubrication, etc.

Scheduled Compliance: The scheduling of maintenance labor in coordination with operations, contractors, engineering, and safety personnel to minimize interruption to operations and production. Also, to ensure the work is completed on time, effectively, and measured daily and hourly.

Scheduled compliance is measured by dividing the total labor hours available (all maintenance labor hours except people on vacation or sick leave) into the total labor hours completed daily and by week. I know people like to move the work because of issues from day to day. That is acceptable; however, you do not receive compliance for it. The items that are taken away from scheduled compliance will be identified in a Wrench Time Study.

Staying Focused: The Key to Long-Term Maintenance Success

If you want to succeed, take things one step at a time, as I stated in my article, and stay FOCUSED. People love to be successful, and these ideas allow a maintenance crew to be successful. I am telling you these things having been in maintenance management myself; I have seen many companies succeed worldwide following these recommendations. I want to add you to the list.

Do not strive to be “world-class,” but be your best.

Questions?Email Ricky Smith at rsmith@worldclassmaintenance.org