Culture Eats Strategy for Breakfast

As management guru Peter Drucker famously said, “Culture eats strategy for breakfast.” No matter how well-crafted your maintenance plans, digital twins, or predictive analytics programs are, you’re fighting a losing battle if your culture doesn’t prioritize reliability.

This is where High-Reliability Organization (HRO) principles and the Toyota Production System (TPS) intersect. HROs—like nuclear power, aviation, and healthcare—master risk management. TPS has revolutionized manufacturing with its relentless pursuit of efficiency and quality. Together, they create a roadmap for building an enduring high-reliability culture (Figure 1).

Figure 1: High-Reliability Organization (HRO) principles and the Toyota Production System complement one another.

But let’s be honest—not every industry can afford to implement HRO and TPS elements in their purest form. Paper mills, mining operations, petrochemical plants, and metals facilities operate under different constraints than a nuclear submarine or a Toyota assembly line. This guide cuts through the noise, showing you what you can afford to do—and what you can’t.

The Five Pillars of a High-Reliability Culture

1. Preoccupation with Failure = Jidoka (Built-in Quality)

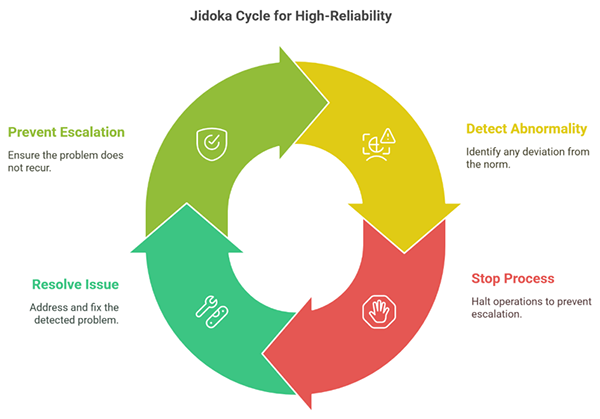

High-reliability organizations treat small failures as warning signs of bigger problems. Toyota’s Jidoka (automation with human intelligence) does the same—when an abnormality is detected, the process stops, and the issue is resolved before it escalates (Figure 2).

Figure 2: TPS Jidoka and the HRO’s preoccupation with failure synergize beautifully.

Culture Shift:

- Move from a “run-to-failure” mentality to a prevention-first mindset.

- Teach employees that reporting minor issues isn’t a hassle—it’s a responsibility.

- “Problems are a good thing. Repeating them is not.” – TPS Sensei Ed Welch, Toyota True Lean Center, University of Kentucky (Retired Toyota).

What You Can Afford:

- Near-miss reporting systems with “no blame, no shame” policies.

- Daily safety huddles where workers surface minor concerns before they become crises.

- Condition monitoring—even if just simple visual inspections, oil analysis, and vibration checks.

What Might Be Too Expensive:

- Full-scale AI-driven predictive maintenance platforms.

- Dedicated human factors teams—train existing teams instead.

2. Reluctance to Simplify = Genchi Genbutsu (Go and See)

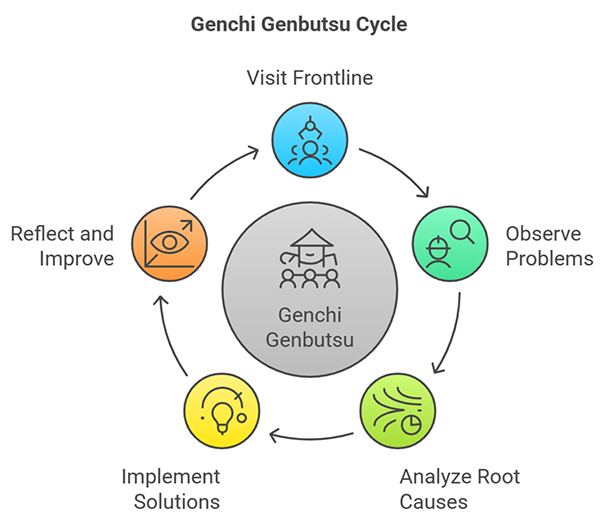

HROs avoid oversimplifying root causes. Toyota’s Genchi Genbutsu (“Go and See”) is about leaders visiting the frontline to observe problems firsthand instead of relying on reports (Figure 3).

Figure 3: Solving problems at a too high level or in the boardroom is a common mistake. The HRO’s reluctance to simplify marries well with the TPS Genchi Gumbutsu Cycle.

Culture Shift:

- Stop blaming failures on “operator error”—dig deeper.

- Leaders need to spend time at the Gemba (the place where work happens).

- Use structured A3 problem-solving instead of jumping to quick fixes.

What You Can Afford:

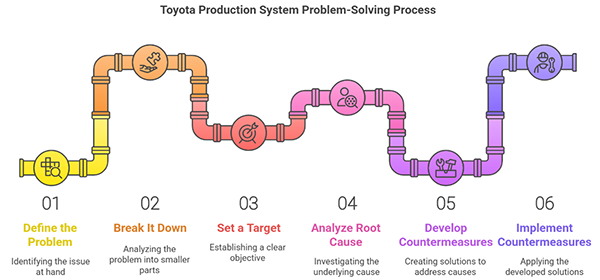

- TPS 8-Step Problem-Solving Process—Define the problem, break it down, set a target, analyze the root cause, develop countermeasures, implement them, verify results, and standardize (Figure 4).

- Five Whys analysis for every critical failure.

- Gemba walks—supervisors spending at least 30% of their time on the floor.

Figure 4: The TPS 8-step Problem-Solving Process and A3 Thinking help avoid simplifying problems, especially step 2 – breaking down problems into smaller parts. If in step 4, you don’t get to a single cause, go back to step 2 and break the problem down further.

What Might Be Too Expensive:

- Hiring outside consultants for every root cause analysis.

- Deploying massive digital twins for real-time monitoring of all assets.

3. Sensitivity to Operations = Kaizen (Continuous Improvement)

HROs are tuned into weak signals that indicate future failures. Toyota’s Kaizen (continuous improvement) thrives on empowering workers to call out inefficiencies and improve processes.

Culture Shift:

- Reliability isn’t a department—it’s everyone’s job.

- Encourage operators to slow down to speed up—small improvements today prevent breakdowns tomorrow.

- Create a culture where problems aren’t hidden—they’re celebrated as learning opportunities.

What You Can Afford:

- Kaizen boards where workers track minor improvements.

- Structured peer verification to detect anomalies in real time.

- Mini-Kaizen sessions focused on improving maintenance procedures.

What Might Be Too Expensive:

- Large-scale workforce restructuring to mirror Toyota’s model.

- Highly specialized, consultant-driven Kaizen events.

4. Commitment to Resilience = Heijunka (Level Loading)

HROs don’t just prevent failures—they build resilience. Toyota’s Heijunka (level scheduling) balances workloads to prevent fatigue and errors.

Culture Shift:

- Stop relying on heroic firefighting—make stability the goal. As I’ve previously written, what gets rewarded gets done. If you celebrate the technician who pulls an all-nighter to fix a crisis but fail to recognize the team that prevented the crisis in the first place, you’re reinforcing the wrong behaviors.

- Prevent worker overload, which leads to mistakes and unsafe shortcuts.

- Prepare teams for error recovery, not just error prevention.

What You Can Afford:

- Cross-training to ensure flexibility during high-demand periods.

- Load leveling for maintenance schedules—avoid overloading certain weeks.

- Tabletop drills for high-risk failure scenarios.

What Might Be Too Expensive:

- Large-scale redundancy of critical assets.

- Full-blown disaster recovery simulations (instead, focus on tabletop planning).

5. Deference to Expertise = Respect for People and Teamwork

In HROs, the most knowledgeable person—not the highest-ranking—makes the decision. Toyota’s Respect for People ensures expertise is valued at all levels (Figure5).

Figure 5: It’s rarely the highest-ranking person in the organization who best understands problems and opportunities, and they often don’t really know how to solve problems at the right level. A leader’s role is to set the vision and enable people. This is clearly understood in TPS and HROs.

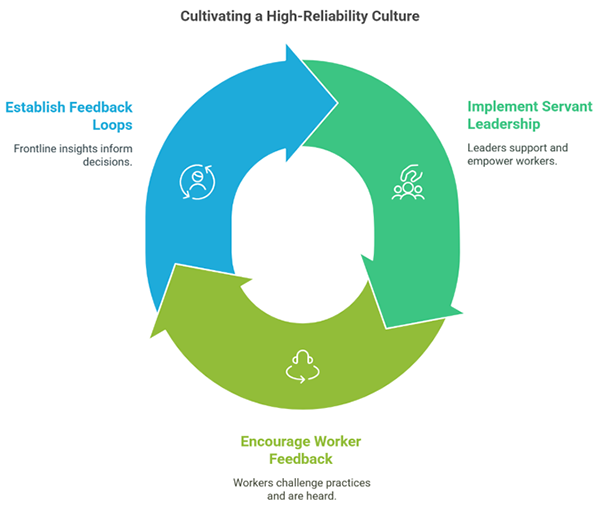

Culture Shift:

- Move from “command and control” to servant leadership—leaders support workers.

- Create a culture where workers challenge unsafe or unreliable practices—and get listened to.

- Build structured feedback loops where frontline insights drive leadership decisions.

What You Can Afford:

- Obeya (big-room problem-solving) to include cross-functional expertise.

- Idea-sharing platforms where workers submit reliability improvements.

- Structured mentoring programs for technical knowledge transfer.

What Might Be Too Expensive:

- Fully democratized decision-making (hierarchy is still necessary in some cases).

- A complete overhaul of organizational structure to mirror Toyota’s.

Final Thoughts: Transforming Culture, Not Just Processes

Blending TPS efficiency with HRO reliability creates an unstoppable force—a culture that prevents failure, continuously improves, and responds with resilience.

Reliability isn’t just about technology or process. It’s about mindset. Organizations that commit to prevention, curiosity, weak-signal detection, resilience, and frontline expertise will outperform those that rely on brute-force maintenance or after-the-fact root cause analysis.

If your organization is serious about long-term reliability, stop thinking about reliability as a department or an initiative. Make it your culture.