Although the concept of predictive maintenance (PdM) is now widely known and its potential benefits are generally accepted, many plants have failed to exploit the available techniques and technologies successfully. This situation begs the question: “Why do some programs succeed while others fail?”

In times when budgets tighten and resources are stretched, maintenance teams are often asked to do more with less. These moments demand a smarter, more efficient approach to conducting maintenance, whether refining internal processes or seeking external support. The organizations that thrive implement best practices, invest in long-term infrastructure, and position themselves to accelerate performance when conditions improve.

I’m going to address the subject of why PdM programs succeed or fail from the managerial, technical, and financial perspectives. Whether one decides to use this information to beef up or restart an in-house program, determine what type of training may be best, or outsource some or all of these functions, the hope is to provide enough practical information to help you be successful in your endeavor.

Vision Without Strategy Falls Flat

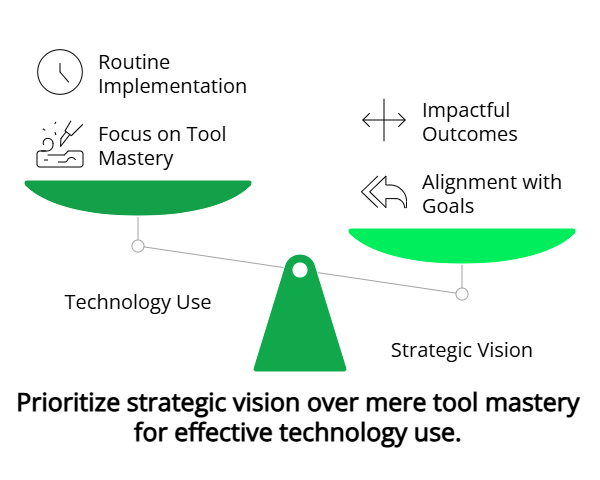

No program can succeed if it is not well conceived. A predictive maintenance program should change the maintenance department’s culture, philosophy, and workflow if done correctly. It is not just the addition of a new technology or tool, but a different approach or strategy towards maintaining one’s assets.

Adopting new technologies without changing maintenance strategies will not produce the desired benefits.

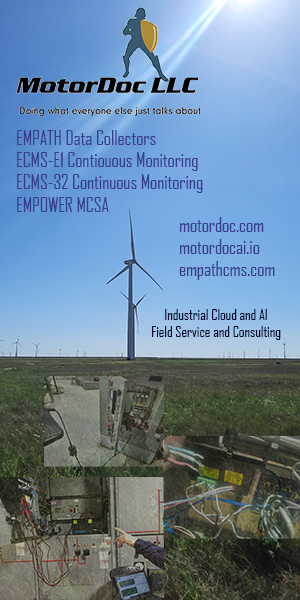

This approach is being undertaken in order to gain specific benefits that can and should be measured. These benefits include: increased uptime, reduced failures, shorter planned outages, fewer preventive maintenance actions, and, ultimately, a more efficient facility.

Failure to adapt the culture to this new philosophy and benchmark the gains will eventually lead to the program’s dissolution. Adopting new technologies without changing maintenance strategies will not produce the desired benefits.

When the ‘Why’ Gets Ignored, Tools Fail

Many facilities purchase a new technology, such as a vibration data collector or alignment tool, spend time and money learning how to use the tool, but little time understanding why it is being used.

For example, a facility I know of had the capacity and ability to detect incipient bearing wear in a pump using a vibration analysis system. Although the pump showed no signs of wear, the facility changed the bearings according to their preventive maintenance schedule.

At another plant, a vibration analyst was adept at detecting mechanical faults in his plant’s machinery. Still, he was afraid to tell his supervisor about all of the problems he found because his supervisor might get angry at having to repair all of these machines! Both of these cases demonstrate the use of the technology as an end in itself without an overall vision of why the technology is being employed.

Failure to Justify the Program

I have often seen a program fail in those facilities where the technology is being used correctly and in the right context because its successes were not adequately documented. This is to say that the facility changed its philosophy to a predictive mode, correctly employed technology to reduce preventive maintenance actions, and minimized catastrophic failures.

If you can’t prove value to leadership, your program is always at risk.

Still, they failed to document the efficiencies and savings of these actions adequately. So, while employees within the maintenance department acknowledged that their work was useful, they had no data to prove this to those outside of their group.

Sadly, they saw their program cut when managers had to tighten their budgets. In other cases, the person managing the PdM program left, and no one picked up the ball.

Inconsistency Kills Momentum and Trust

Another component of a failed program is the lack of consistency over time. There are many causes for this, ranging from a failure to commit adequate personnel, lack of proper training, loss of skilled personnel, change in program direction/technology, failure to define the program at the start adequately and, finally, the lack of a consistent model to monitor the efficacy of the program over time.

These false starts and stops add confusion to the process and typically result in a lack of faith by the workers who see the company invest in “change”, but then quickly revert to old patterns.

False starts and quick reversals destroy trust—and kill PdM programs.

A lack of consistency over time has the additional ill effects of not allowing the facility to “evolve” to a proactive maintenance mode. As a brief review, there are four levels of maintenance practices: run-to-failure, preventive, predictive, and proactive. In run-to-failure programs, facilities adopt a technology like vibration analysis to test or troubleshoot machines they know have problems.

Preventive mode refers to maintenance departments that test machines on a schedule, much like a preventive maintenance task, but do not act on the information gleaned from these tests. In predictive maintenance mode, one bases maintenance actions on the results of these tests to eliminate unnecessary preventive actions and avoid catastrophic failures.

The next stage in maintenance evolution is the proactive mode, whereby the facility has enough historical information about the machines and their failure modes to make educated decisions on how to extend their lives, replace them with machines of different makes or models, or weed out inherent design flaws.

To reach these lofty goals and bask in the glory of a highly efficient plant, one needs the backbone of a historically consistent program to lean on.

Looking at these evolutionary stages from a qualitative viewpoint, one will note that a plant in run-to-failure mode will contain machinery in various states of disrepair that seem to fail at random. Personnel in a run-to-failure plant will often be “busy” and may think they are too busy to adopt new procedures! In the preventative mode, one is taking better care of one’s assets, and they are failing less frequently.

In predictive mode, one should be able to reduce preventive actions where applicable, extend machine life, and drastically reduce unplanned outages. In proactive mode, one will have removed or redesigned troubled machinery and will have a plant that operates smoothly, predictably, and efficiently over time. To attain this goal, consistency is required over a long period.

Training and Partnering

Ongoing training is an important ingredient of a successful program. However, it needs to be the correct type of training, a combination of complementary technology and managerial expertise. ISO and ASNT-certified vibration courses focus on machine dynamics and vibrations on a general technical level.

Taking these courses, passing the exams, and becoming certified is important, but this training alone will not necessarily translate to running a successful PdM program.

Equipment vendor training is often helpful because it requires trainees to learn how to use a data collector and correctly set up software. However, it usually does not expand outside these topics to provide the user with the tools he or she needs to run a successful program.

While learning how to use data collection tools is an essential skill, it defeats the purpose if that same person does not know what to do with the data they’ve collected or how to manage a successful PdM program. One last note to consider about equipment vendor training: once the training has been completed, there is often no one around to ensure employees use the tool correctly.

Certifications teach the tool – success comes from knowing how to run the program.

On-site training, database reviews, program audits, and choosing the correct long-term partner, or PdM service provider, will go a long way to ensuring a successful program.

If done correctly, a service partner will provide onsite training and support in managing your ongoing program in different capacities as your program evolves. At different times and circumstances, a good partner will take over parts of the program for you and later provide training and support as you bring the program back in-house.

Without Standard Methods, Data Falls Apart

As alluded to in the last section, a successful monitoring program is more than just interpreting graphs and data; it depends on consistency and repeatable performance. We are generally interested in monitoring assets to diagnose deteriorating health or other problems.

To do this correctly and accurately, one needs to test the assets repeatedly, month after month, and year after year for many years. When this is understood, one will see that a successful program depends much more on consistency and program management (unfortunately, this aspect is not often taught in standardized courses) than it does on technical prowess.

Another way to state this is that a successful program depends on methodology and organization. A good partner or service provider with a good track record should be able to help you implement a program with tried-and-true methodologies and manage it for you.

Good Intentions Without Follow-Through

So far, we have touched on several aspects of successful and unsuccessful programs, and it may be clear that many issues are involved. This highlights another problem: a lack of experience and/or commitment by a particular facility.

Even if one has the best intentions and the highest level of commitment, it may take a long time to train an employee or group of employees to the point where they can implement a good maintenance program. In the meantime, little may happen, or things may go wrong as they learn.

More typically, one will see a facility trying to accomplish a great deal without dedicating any money or people to the project, or, when they do dedicate one or the other, it is only for a short period. Within this window, corporate priorities change, personnel change positions, and the program gets shelved.

Like many things in today’s world, PdM is becoming a highly specialized area of expertise where, if one wants to gain the depth and expertise currently existing in the market place, it takes a great deal of dedication and time, which, unfortunately, may not be compatible with the other 100 duties you are expected to take care of as part of your other work.

This is one reason why partnering or outsourcing has become a viable option for many organizations.

What It Takes to Win with PdM

Having gone through this brief exercise, perhaps it is becoming apparent why there are advantages to outsourcing PdM programs. And, while many companies have the expertise in-house to develop and sustain high-quality PdM programs, many companies might benefit more, or at least benefit more quickly, by outsourcing their predictive maintenance programs. It is a decision that each organization needs to explore for itself.

Service providers understand the context in which their technology is being employed, and many have extensive experience in successfully managing large programs over extended periods.

The best partners don’t just bring tools – they bring staying power.

They know what is required to make a program succeed and can educate you and your staff on these points. A service provider should maintain a consistent approach over time and be able to maintain the appropriate expertise within their company, in part because their people completely believe in the technology they are employing.

They will be experts at utilizing the tools and technology, but this should take a backseat to their track record on managing long-term programs. Lastly, a service provider should be able to work with you to benchmark the program and demonstrate its return on investment over time.