We will focus on the Institute of Electrical and Electronics Engineers, Inc. (IEEE) Standard 43 and the in-development IEEE P97 for brevity. IEEE 43 is titled “IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery,” and P97 is the “Draft Trial-Use Recommended Practice for Diagnostic Test Methods for AC Electric Machinery Using Direct Voltage,” with the note that the P97 title will most likely change.

With IEEE standards, the recommended practice is a guide (another term) that uses terms such as ‘should.’ If the title states ‘Standard for…’, it will use terms such as ‘shall”. Trial use means that it represents relatively new practices that have limited field experience.

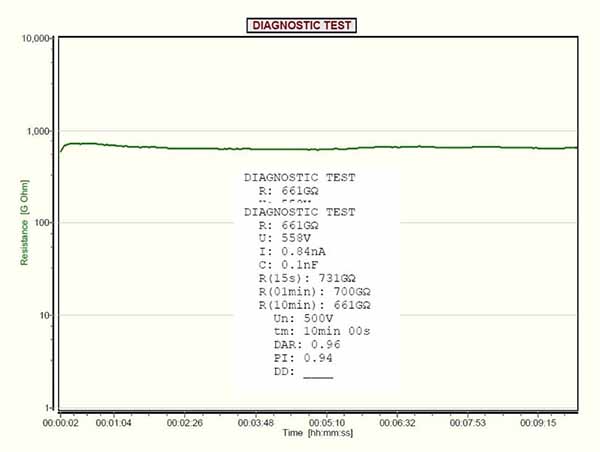

Insulation Resistance Profile testing of a 1 Megawatt hydro rotor during onsite overhaul.

IEEE Std 43-1974 underwent an extreme rewrite in what would become IEEE Std 43-2000 and another set of major changes in the version IEEE Std 43-2013.

As I write this, I am a week past our discussion of changes to the next version of IEEE Std 43, which was held as part of the IEEE Power Engineering Society Materials Subcommittee bi-annual working group held at Siemens in Pittsburgh, PA.

We worked on a number of additional standards, such as IEEE P97 and IEEE Std 62.2, “Guide for Diagnostic Field Testing of Electric Power Apparatus – Electric Machinery,” which we will discuss in a future article.

During the standards meeting, one of the serious issues was part of the trend in the late 1990s and early 2000s to lean out standards. During this period, one of the areas that was impacted was the inclusion of educational material, such as Annex A in IEEE 43, which identified how to dry windings without damaging them.

With the transition of the workforce and the situation related to two hurricanes around the beginning of October 2024, instructions such as these were discussed as possibly being reintroduced into standards.

Note: I may identify possibilities related to in-process standards. However, as these are consensus standards, they may change based on comments, committee makeup, and discussions, including during the voting period.

The 1974 Version of IEEE 43

When considering insulation resistance minimums of 1 Megohm plus 1 Megohm per kilovolt rating of the machine, we are looking at insulation systems before 1970 and the recommended values in the 1974 version of IEEE Std 43. Temperature correction happens to 40°C using a single table in which the insulation resistance halves for every 10°C below 40°C and doubles for every 10°C over 40°C.

For example, if I had an insulation system tested under this standard and the value was 100 Megohms at 20°C, it would be half and then half again, or 1/4th of the original value to 25 Megohms.

Polarization Index (PI) is outlined as a ten-minute to one-minute ratio that does not require temperature correction and only mentions temperature as an issue if the insulation system is greater than 40°C. In these cases, you would re-test the PI at a temperature below 40°C.

Additionally, there were absolute ratios involved based on the insulation thermal rating such that Class A (105°C) allowed for a 1.5 ratio, and Class B (130°C) and Class F (155°C) allowed for a 2.0 ratio. There was no mention of Dielectric Absorption (DA) and there was a section that discussed the use of the PI for monitoring the drying of an insulation system.

An extremely important part of IEEE 43-1974 was Annex A (Informative). There were key sections that included:

- A1 – Prevention of Moisture Absorption in Winding Insulation of Rotating Machines: in this section, methods for keeping insulation systems dry are discussed as many systems would suffer adsorption where a change in temperature would result in insulation being drawn into the windings.

- A2 – Removal of Moisture from Winding Insulation of Rotating Machines: these were the processes used to increase temperature with limits and times and how to determine if the winding is dry.

- A3 – Methods of Heating Machine Windings: which included how to set up heaters, create an oven with the motor (without rotor in place) and using field winding power. These included how to dry DC machines as well as AC machines.

The 2000 Version of IEEE 43

This was a complete and major rewrite of the 1974 version in which there was more discussion of what made up insulation resistance in terms of electrical charges. Proper voltages were defined based on the winding voltage rating, and adjustments were still made at 10°C changes to 40°C. The PI ratings were the same but Class H is added to the PI ratio.

In this version, several more changes were made involving PI ratios only being applicable when the insulation values are less than 5000 Megohms and a change in the insulation resistance values for pass/fail, which included the 1 Megohm plus 1 Megohm per kilovolt rating, but for insulation systems before 1970.

Insulation resistance of 5 Megohms was set for random and form wound motors under 1,000 volt rated and 100 Megohms for most AC form windings and DC armatures built after 1970. Somehow, the DC armature limitation existed, which was later removed in the 2013 version.

One of the interesting changes that came about at this time was the beginning discussion related to PI on field windings. This section focused on rotor field windings in which the reference is that many don’t have insulation between the coils and the field cores.

At the time, this was introduced by motor manufacturers primarily to reduce the frequent low PI’s that occurred during inspection tests.

It is also important to note that starting in the 2000 version, the standard notes that the purpose of the insulation resistance and PI tests are to verify whether the insulation system is suitable for high voltage tests. Generally, these are not meant to be pass/fail tests but are condition indicators.

The 2013 Version of IEEE 43

The evolution of IEEE Std 43 reflects a shift from basic insulation testing to a nuanced approach incorporating temperature correction, polarization index, and diagnostic test methods.

The 2013 version made additional changes, including more discussion on insulation resistance, PI, and Dielectric Absorption (DA), as well as the addition of Annexes associated with DA, DC versus AC testing, charge and discharge currents (polarization/de-polarization), and the Insulation Resistance Profile (Annex D).

The original section on the IRP was several pages long, but the committee moved this section to a new standard that would provide more information and detail (IEEE P97).

Example of IRP on synchronous motor rotor with some moisture present.

The addition of a section on ‘Interpretation of Insulation Resistance and Polarization Index Test Results’ identified methods for trending both values. Definitions of what can cause the changes from good to poor readings are discussed, and a section on determining suitability for operation and continued testing was added.

The rather interesting discussions surrounding the newer standards included returning the ability to test field windings that are insulated. Additionally, there was a discussion about eliminating specific testing on random wound machines, including PI and DA, which was objected to by most of us who do these tests.

There was further discussion about why the limitations should occur, again from the OEMs primarily. Which has again become a discussion in the present work on this standard. The DC armature limitation was removed from the standard.

One of the more significant changes to the standard was the adjustments for temperature to 40°C. Instead of the straight 10°C adjustments, the changes are made based on the type of insulation system. The challenge discussed is how machine owners will understand what type of insulation system their motors have.

Present Work on the IEEE 43 Standard

At the time of this article, the work on the latest version of 43 is in process. The same issues have been brought up, including insulation resistance, DA and PI of random wound machines, and the rotor fields. There will be a few areas that will be moved to IEEE P97.

Overview of P97

IEEE P97, in development, aims to offer enhanced diagnostic capabilities for AC electric machinery, including tests for moisture, contamination, and insulation degradation.

Several tests were determined to be too cumbersome for IEEE 43, and the concept for IEEE Std 97 was initiated by the PES Materials Subcommittee and led by Hydro Quebec. There were three specific tests at the time of this article, including the DC Proof Test, DC Ramp Test, Polarization Depolarization Current Test, and Insulation Resistance Profile.

The DC ramp test is the hipot test, which is IEEE Std 95, “IEEE Recommended Practice for Insulation Testing of AC Electric Machinery (2300 V and Above) with High Direct Voltage,” which is also being updated.

The present description of the standard, which may change, is as follows:

IEEE 43 is the recommended practice for insulation resistance (IR) and polarization index (PI) of rotor and stator windings. IEEE 43 provides guidance for test voltages and acceptable levels of insulation resistance and polarization index. IEEE 95 is the recommended practice that presents the methods for performing a DC overvoltage test on rotor and stator windings and suggests the withstand test voltages.

Both these DC test standards provide basic go/no go information on whether a machine winding can be placed into (or returned to) service. Neither standard gives guidance on analysis methods that enable users to extract more information on the winding insulation condition from DC tests. Specifically, certain DC tests may identify the root cause of insulation problems or aging and perhaps the severity of the problem. This Guide presents DC test methods that may provide additional diagnostic information about rotating machine ground wall insulation condition.

The tests outlined in P57 are aimed at determining:

- Thermal and electrical degradation.

- Incomplete curing of the insulation system.

- Degradation of the stress control coating.

- Moisture on the insulation.

- Tape separation or delamination.

The present iteration includes recommended steps, including the impact of cable length, types of insulation materials, and effects of aging, in addition to other conditions and applications. For such things as IRP, patterns and interpretations of the test results are identified. This document is expected to go for a vote in 2025.

The insulation resistance standard IEEE 43 is presently undergoing another review. Since the 1974 version, major changes have occurred, with a few changes that need to be returned to the latest edition. It is important to note that in the latest versions, there is some guidance on pass/fail, result meanings, and how to adjust to 40°C in newer insulation systems.

Many insulation resistance testing instruments still refer to the limits in the 1974 version of the standard. Several tests mentioned in the 2013 version of the standard have been moved to IEEE P97, which provides a deeper discussion, detail, and interpretation of the different results.