Ask any maintenance professional working in an industrial setting if they want to see a weekly work schedule developed; they will reply in the affirmative. Now, sit them down and explain how much effort and coordination it will take to achieve this, and most will run for the hills.

The individual activities we carry out to develop and execute a weekly maintenance schedule are pretty straightforward, but the coordination and discipline required to carry them out represent one of the organization’s biggest challenges.

Without a weekly schedule, urgency—not importance—dictates what gets done.

So why bother? We must develop and execute a weekly maintenance schedule to the best of our abilities for two simple reasons. We do this to:

- Ensure that the most critical work is completed first

- Maximize wrench time

How Scheduling Aligns Work With True Priorities

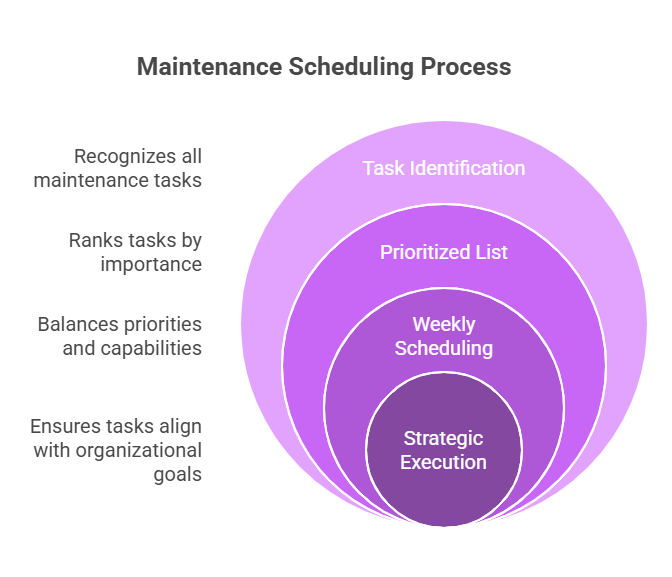

It is a bit of a separate discussion. Still, if we had a good handle on all of the work that must be completed by the maintenance department (corrective, construction, preventive, predictive, etc.), and if we have a system for prioritizing this work, then we should be able to pick list these jobs in order of importance.

Additionally, if we had such a list, we would logically pick from the top each time we needed to find something for our people to do.

The problem with this idea is that this list of prioritized work is quite long and complex and often shifts based on recent events. It is tough for any individual to have a complete and clear grasp of priorities at any given moment. Maintenance supervisors assigning work to their people will assign what is fresh and recent in their minds but not necessarily the top job from the prioritized list.

Through a weekly scheduling process, the organization is forced to look at the entire prioritized list and come up with a weekly maintenance schedule that represents the shared priorities of operations and maintenance, as well as their capabilities for the coming week.

When we make scheduling and prioritization decisions on the fly, the most recent flare-up floats to the surface, which is not necessarily the most strategically vital activity to be performed.

Boosting Wrench Time Through Better Planning

Be very careful who you talk to about wrench time and how you approach it. If you are not careful, you will end up in a situation where the top of the organizational chart thinks that people are not working hard enough, and the bottom of the chart thinks you are unjustly calling them lazy. Neither is true.

Wrench time is that portion of a tradesperson’s day that is spent positively affecting the assets. In its simplest form, this means a wrench is on the equipment. Most estimates place this percentage of time in the 20‐30% range, with top performers often considered as those who operate in the 50‐55% range.

Even among the best organizations, at least 45% of the time is lost to non‐wrench time activities such as travel time, trips to the storeroom, waiting for instructions, waiting for equipment, etc. We will never eliminate these activities, but with discipline, we can shrink them and bring our performance into the 50% range.

What is one of the common traits among those top performers? They all develop a weekly maintenance work schedule that is agreed upon, widely communicated, and followed as closely as possible.

The worst thing you can do is hand a tradesperson a work order and say, “Come find me when you are done with that, and I will give you your next assignment.” Engaging your employees with this lack of the big picture leads to significant losses in productivity and morale. As a result, you will be lucky to operate at the 20% wrench time marker.

Top performers don’t just work hard—they work a schedule built on priorities.

Develop a schedule that covers 100% of available time and actively (face‐to‐face) communicate this schedule to the affected employees in advance. You will automatically see a boost in productivity within your organization.

Handling Emergencies Without Derailing the Schedule

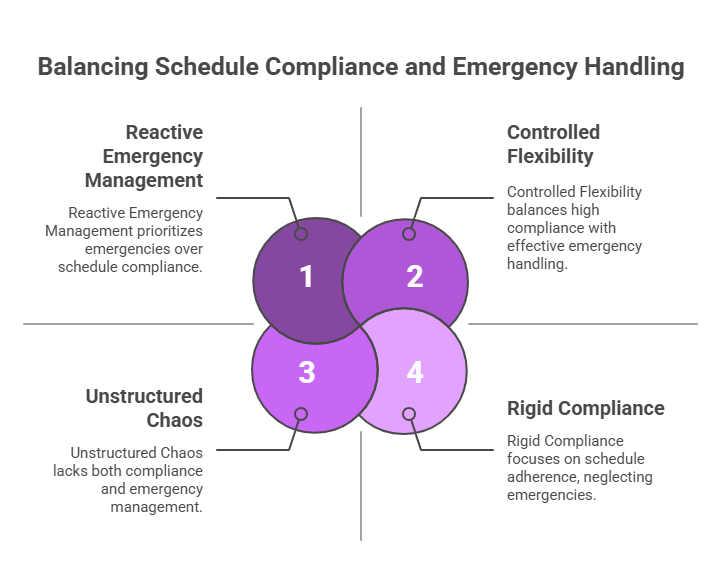

The counterargument to scheduling to 100% availability is: “How will we handle emergencies?” The answer is simple if you can accept a few simple facts.

Controlled Flexibility: When It’s OK to Break the Schedule

It is acceptable to break the schedule as long as it is done in a formal and controlled fashion. Have clear definitions of what is an emergency and what is not. Something must be removed if you add an emergency job to the schedule. Let’s control it and ask why; maybe we can do something to prevent this particular emergency from occurring again.

You can break the schedule – but only if you control how and why.

Why 100% Schedule Compliance Isn’t the Goal

We are not going to achieve 100% schedule compliance. From a young age, we are conditioned to look for perfection in our performance. The weekly scheduling process requires us to be open and honest about our performance. More desirable than 100% compliance (usually a sign of making the numbers fit the crime) is a 5‐10% improvement over last year’s performance.

Discipline in Scheduling Drives Long-Term Reliability

Please make no mistake: the discipline required to develop and execute a weekly maintenance schedule is significant and, quite possibly, the hardest thing we have to do within the maintenance organization.

We always feel like we can cut a corner today and catch back up tomorrow. Sadly, tomorrow never seems to come. When doing something difficult, remembering why we are doing it is often beneficial.

Maximizing wrench time and prioritizing work will lead to asset reliability performance that we can all be proud of.