When I was a plant manager years ago, my operations manager asked me for permission to hire four new workers to help keep up with demand. He said he could not keep up with the work and needed extra help to manage the workload. I denied his request.

Why? Because he came to me with an emotional request rather than a fact-based, data-driven business case as to why we needed to add workers. Leaders cannot make business decisions based on emotions.

Adding staff or equipment only makes sense if it increases the value to the organization and offsets the additional financial burden. The challenge for managers is successfully creating and presenting such a request.

Leaders don’t approve feelings – they approve ROI.

Framing Requests in Terms Leadership Understands

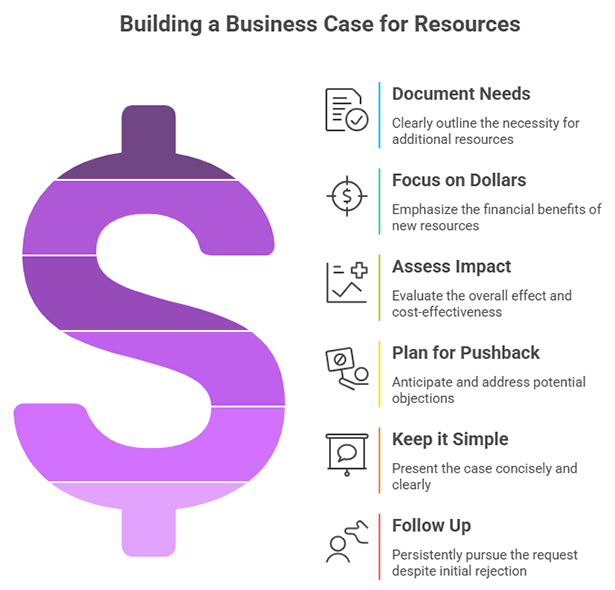

Making the financial case for hiring new workers requires that maintenance and engineering managers gather, analyze, present, and support their requests in terms that financial types and top executives can understand and buy into. These suggestions can help managers build the business case for adding new employees.

Document needs. Put down in writing what is not getting done due to a shortage of technicians. A strong case might be as simple as noting the percentage of overtime technicians currently average. In some cases, the premium dollars spent on overtime cover the cost of an additional employee.

Focus on dollars. Managers should note the amount of money the company loses by not having a fully staffed team. Make sure to include tasks not getting done that a new person could do and the anticipated short- and long-term benefits to the department and company.

Assess the impact. List the total cost, including benefits, of the new position. Focus on the way the benefits will outweigh the costs. For example, how soon can the organization expect the new positions to pay for themselves? Also, give details on the position’s reporting structure and how it will interact with existing positions. Top executives must be clear about the benefits and emphasize communicating with current staff to maintain morale. Bringing in a new resource at higher pay, grade, or position can cause morale problems.

If you can’t show how it pays off, don’t expect a yes.

Plan for pushback. Anticipate and address objections and resistance. When building the business case to add workers, managers must ask themselves the same questions they expect executives and staff to ask. By preparing for this type of pushback or objections, managers will be ready to answer them intelligently and confidently.

Keep it simple. The request should be two pages at the most — ideally, with bullet points. Make it easy to skim, and be sure critical points stand out. Do not assume everyone will read a lengthy dissertation. This is an executive summary of the request to add resources. Hopefully, we will have time to discuss the request in greater detail. At first, keep it simple.

Follow up. It amazes me how many managers give up when the initial answer is no. If the need is real, keep pushing forward. The first go-around apparently did not show enough need or stress the pain points. Reformulate the request to gain support.

Managers can employ the same approach to building a financial case for buying new equipment. When is the right time? There are no coupons in the Sunday paper and no Labor Day sales or end-of-model-year closeouts in this case.

Focus on the future. Assess current needs, constraints, and future requirements. It is important to understand the objectives in making such a request. Is the goal to increase productivity? Will this new equipment make the department more effective, translating to happier customers? Can I upgrade instead of buying new equipment and still get better performance? Does the company plan to expand, requiring increased equipment demand? Following the aforementioned suggestions, managers can develop a solid business case to justify budgeting for new equipment.

Find a partner. Once funds have been budgeted, the next step is to research and locate the best suppliers or vendors. The Internet provides access to a range of specialized equipment companies, so take the time to research. Check out articles that target the specific type of facility you work in, and attend shows and conferences with technicians to spend hands-on time with equipment and talk with actual users.

Kick the tires. Managers should next research the piece of equipment they have identified. One of my checklist items was to get three references of similar equipment that current customers had purchased. I asked the procurement and maintenance managers for their opinions on the equipment.

Look at life cycle. When calculating costs, ensure that you include all life-cycle costs, encompassing expenses associated with design, procurement, storage, installation, start-up, operation, maintenance, decommissioning, and removal. Nearly 95 percent of equipment reliability and maintainability is baked into the equipment during the design phase, so these costs are knowable.

Look for trouble. Reliability should be designed into the new equipment. Ask the original equipment manufacturer for failure modes and effects analysis or reliability-centered maintenance data. Ensure the contract includes training and competency assurance for operations and maintenance.

What Success Looks Like in Practice

This process for making a financial case for investments works. Eventually, the operations manager returned to me with a well-thought-out plan and justification for adding additional employees. He made the case that deliveries were falling behind and that the only way to keep up with demand was to mandate overtime and supplement with temporary help. We agreed to add three employees, not the four he wanted.

When I had to buy a new compressor, I talked to a manager who recently purchased the same unit. He told me the real truth about the unit’s reliability, the amount he had spent on the recommended spare parts, the headaches he had to endure to fix the problems the installation team caused, and the hours of work it took from his maintenance team that they could have spent on other work.

Justifying investment isn’t about asking – it’s about proving.

As you build the business case for adding employees or capital equipment, keep in mind the universal objectives of every company: having productive employees and using resources as efficiently as possible.