Before any reliability project or initiative can begin, a business case must be established, and the financial benefit or risk must be determined. In this chapter, we will deal more with financial risk rather than business risk as it pertains to safety or environmental issues.

To determine the ROI (return on investment), the objective for the reliability initiative must first be established. The initiative’s objective should have a financial value assigned. An example may be:

Reliability Objective: Increase the reliability of production assets on a specified production line by 8% with a financial value of $ 8 million in the first year.

Developing the initiative’s objective and assigning value to the objective is important to receive management’s approval. The objective above could be broken down further into more defined measurements to include:

- Increase the number of units produced in year 1, year 2, year 3, etc.

- Reduction in unit cost per unit in year 1, year 2, etc.

- Increase in quality yield by % in year 1, year 2, etc.

- Reduction in maintenance cost by 10% in year 2, 20% in year 3, and 30% in year 3 based on current maintenance material, labor, and contractor cost

Leadership ROI Team

The first step in this process is to develop a team of professionals who would jointly develop the business case, which includes the ROI. This team must consist of the plant or corporate financial person, production leadership, maintenance and engineering leadership, and plant or executive management.

Often, any of these personnel will try not to participate in this process; however, if they do not participate, the chance of the initiative being approved is very low. I always ask managers how much their time is valued. In most reliability initiatives, the value is so high that they have no option but to participate.

Case Study

An example of this value would be a situation in which I would change the names to protect the company’s true identity.

Company name: XYZ Company

Situation: Demand for this plant’s product was expected to double in the next year or two.

- The company was adding additional production lines in the plant to keep up with production demands.

- According to production management, no additional capacity of current assets was available.

- Equipment reliability was a concern because downtime was seen as high (no real numbers available)

- The skill level of maintenance personnel was seen as a problem because of reliability issues, so a “pay for skills” program was implemented, which was seen to have little effect on the reliability issues.

- A new maintenance manager was appointed from engineering.

The Team

- The plant manager developed a team to determine a solution to the reliability problem with real concern that the new production lines will have similar production issues if equipment reliability is not improved.

- The team consisted of the plant manager, production and maintenance manager, engineering manager, plant comptroller, and outside consultant.

Findings

- After evaluating the situation, the management team found the following information valid and agreed upon.

- Asset reliability problems consisted of only 3% of total downtime

- The maintenance department had a PM program developed based on the manufacturer’s recommendations, which was very vague.

- The maintenance department had no repair procedures developed

- Changeover standards were set too high, resulting in a total downtime of 40%

- Changeover standards were developed based on plant startup 6 years prior with no further evaluation for improvement.

- Quality losses exceeding 9% of the production rate due to a lack of good production operating procedures

- Operating procedures were developed after the plant initially started up and were never updated

- Little if any data tracking system could be found

- The computerized maintenance software system was used very little

- The production software system was used well; however, the reported data was invalid.

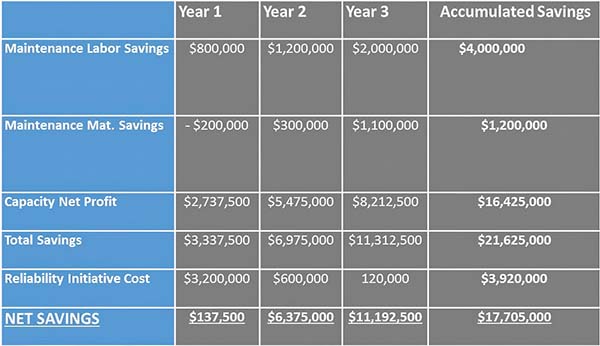

Return on Investment Results

- The plant operated at 57% of the true capacity rate.

- Change over standard was set to high (4-hour change over went to 45 minutes)

- Changeover between shifts cost an average of 15 minutes between shift times two shifts a day.

- Industry-known product quality benchmarks were found to be 3%, whereas this plant’s quality losses were at 9%, resulting in a delta of 6%

- 78% of quality losses were caused by operator error on each production line

- The other losses were a result of many factors

Final Numbers

- Plant capacity increased to 94% within 6 months (sold to corporate as a two-year project)

- Increasing net profit = $12 million

- Capital expenditure was halted, resulting in savings of $4 million.

“Under Commit, over Deliver”

- Quality increase to 4% in one year

- Resulting in an increase in net profit by $800,000

- Maintenance costs increased in the first year by 10%

- Maintenance costs decreased over the next two years by 34% ($420,000)

- Total cost of the project (2 years)

- Production consulting services = $400,000

- Maintenance consulting services = $800,000

- Skills Training = $150,000

- Other cost (training for managers, visits to other plants, etc) = $120,000

- TOTAL COST

- (year 1) = $1.1 million

- (year 2) = $250,000

- INCREASE IN REVENUE

- (year 1) = $13 million

- (year 2) = $4,220,000

In the final analysis, the plant spent $1,350,000 to return $17,220,00. If you notice, the cost was front-end loaded. Corporate was told the expected return was $3,200,000 and not $17,220,000. The cost was stated as estimated. The plant team was “under-committed but over-delivered.” This was one of many situations that actually happened.

Lessons Learned

- Develop a leadership team to identify ROI

- Have the number one financial person on the team provide hard validation of cost and ROI

- Determine where all of the losses may be occurring and focus on the losses worth pursuing. Some losses will always occur, but they must be determined and accepted as part of management’s operating strategy.

- Reliability

- Schedule downtime

- Weekly, monthly, and yearly schedules based on time and not asset health

- Unscheduled downtime

- Rework

- In-effective PM program (apply RCM Methodology such as FMEA, RCM, etc.)

- Total functional failure

- Maintenance cost (this will be reduced as a result of an increase in reliability and reduction in production reactivity)

- Maintenance overtime

- Maintenance labor (never layoff, loose through attrition)

- Maintenance material purchased

- Maintenance storeroom value

- Maintenance material overnight delivery cost

- Maintenance contractor cost

- Maintenance capital (replacing equipment because it was not maintained appropriately)

- Production – if the equipment is not operating to the functional requirements, it produces a loss.

- Product changeovers

- Startups

- Breaks, lunches

- Product quality

- Operator error

- Partial and total functional failure

- Determine the objective of the project or initiative and quantify it

- Under commit, overdeliver every time

- Schedule downtime

- Reliability