In our evolving industrial and production environments, reliability professionals and asset managers are tasked with making sure that equipment is available to safely deliver the desired production volumes, minimizing downtime, maximizing the lifespan of assets, while balancing costs and risks. A tall order!

For most organizations, one of the critical factors that supports delivering these objectives is effective communication. Whether this is within the team, across departments, or with external stakeholders including regulators, customers, and the public, effective communication is the glue that holds it all together.

A Foundation for Successful Asset Management

In my previous articles, it was emphasized that Asset Management is a Team Sport and that the teams need to work together to make informed decisions on when to run physical assets, when to repair them, and when to invest in their replacement.

To make the right call, it is critical that all parties – reliability professionals, maintenance specialists, asset managers, supply chain, finance, management, etc. – are reading from the same page.

Effective communication enables everyone to understand the current condition of the production assets, the current performance data, the future demand from the production assets, and the potential risks and consequences of various maintenance strategies.

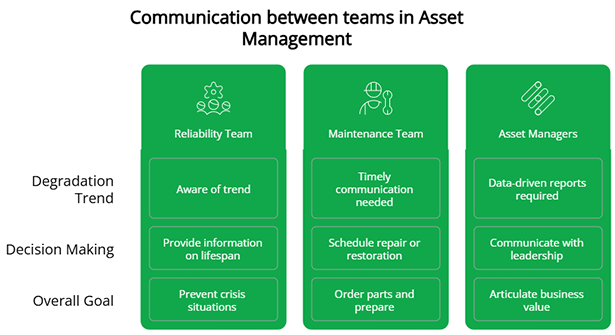

For example, when a reliability team monitoring asset performance becomes aware of a trend that signals an asset is degrading, timely communication with the maintenance team is important. If the maintenance team is not aware of the impending failure in a timely manner, the assets may fail, resulting in downtime, loss, and costly repairs.

By contrast, when a solid communication pathway between the reliability team and the maintenance team exists, the maintenance team is more likely to have the lead time necessary to proactively schedule a repair or restoration, order parts, and generally address the situation before the asset degradation becomes a crisis situation.

Additionally, when the decision to the ‘run, repair, replace’ question for the asset degradation trend is ‘replace’, asset managers must communicate with senior leadership and decision makers to secure funding and people for capital projects or upgrades.

Having solid data-driven reports, timely information from the reliability team on projected lifespan, and the ability to articulate the business value of these investments can help asset managers gain the necessary approvals. Working in silos is not the answer, communication between and across teams is.

Cross-Departmental Collaboration and Communication

Reliability professionals and asset managers rarely work in isolation. They are constantly interacting with departments such as Operations, Engineering, Supply Chain, and IT, each with its own set of priorities and challenges. A key to success is the ability to break down the silos between these departments and bridge any gasp through effective communications.

For example, if the Operations teams notice operational inefficiencies, wear-and-tear on equipment, or are aware of impending changes to production schedules, it is important that they communicate these findings with the reliability and asset management teams. Clear and precise communications will allow the reliability teams to accurately diagnose and take action to prevent equipment failures that may impact production throughput.

Reliability fails when departments don’t talk—communication is the bridge between detection and action.

Collaboration with Supply Management is equally important. Reliability professionals can give the Maintenance and Supply Chain teams advance notice that spare parts will be required to execute repairs and restoration, particularly for work that may not be routine or when parts may have long lead times or are not typically stocked on the warehouse shelves.

Supply Chain teams can then work with vendors to secure parts, avoiding delays or shortages that may lead to prolonged downtime or increased risk as a plant continues to produce without any spare parts on hand.

We are relying more and more heavily on communication technology to manage these cross-departmental interactions. Enterprise Resource Planning (ERP), Enterprise Asset Management (EAM) tools, or Computerized Maintenance Management Systems (CMMS) that integrate between and across other software systems allow for real-time sharing of data, information, and insights, enabling the right people to have the right information at the right time to make decisions.

Communications and Data

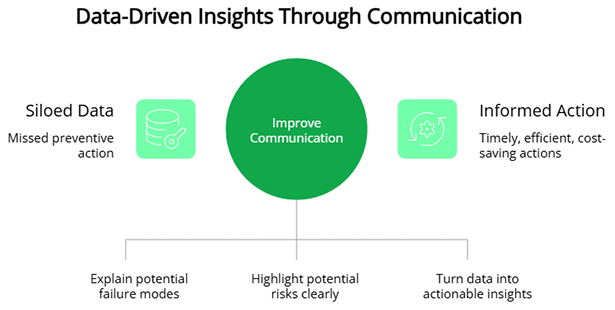

Reliability professionals rely heavily on data to monitor equipment performance and predict when and where a failure may occur. However, data alone is not enough. Without proper communication, this information stays within the reliability team silo and the organization is unable to take advantage of this information, leading to missed opportunities for preventive action.

For example, when instrumentation or sensor data is collected, the next step is for the reliability team to interpret and communicate the results effectively. The maintenance team should receive alerts and reports that explain the potential failure modes, suggested interventions, and the estimated time window to act.

Reliability professionals need to communicate this information, including the urgency and potential risks associated with the recommendations, so that actions can be taken in a timely manner. Maintenance and operations teams receiving this information may be aware of upcoming production shutdown windows, allowing for more efficient scheduling of repairs or similar actions.

Similarly, asset managers must be able to communicate the value and risks associated with assets to leadership, thus enabling the company to invest in the right areas to meet demand and deliver value. Lack of communication between the data collection teams and the decision makers can result in unnecessary spending or missed opportunities for cost-saving investments.

With the explosion of data now available, one of the most significant challenges is turning the vast quantity of complex data into clear, concise, and actionable insights. This becomes a significant focus of the reliability teams.

They must be able to distill these large volumes of data into a story that explains the current asset condition and any potential consequences of inaction. This requires an ability to present data in a way that is meaningful for a variety of stakeholders and obviously requires effective communication skills.

Building the Culture of Effective Communication

Building a culture of effective communication between the reliability and asset management teams, as well as with other key stakeholders, is critical for long-term success. It is one of the best ways to break down the silos between departments. This is not just about sharing data and information, but about creating an environment where collaboration, cooperation, and open discussion are encouraged and valued.

When communication is clear and consistent, we see improved trust between teams, leading to more effective problem solving, faster decision making, and better execution of strategies that are aligned to the company’s goals and objectives. Leaders can demonstrate this culture of communication by how they work together and the expectations that they set for their teams.

Effective communication isn’t just a skill—it’s the foundation of a reliability culture that lasts.

Effective communication can be a learned skill, and training can support building a culture of effective communication. Employees at all levels in the organization should be equipped with the skills necessary to communicate effectively. This goes beyond technical knowledge and includes the ability to listen, ask clarifying questions, and provide constructive feedback.

Leadership can role-model and set expectations by encouraging feedback loops and providing constructive suggestions. This author teaches a course focused on building the business case for maintenance and reliability improvement initiatives. The participants gain the skills necessary to both write and present a business case to decision-makers at their organizations for an actual improvement opportunity, rather than a case study.

The significant improvements seen between week one and the end of the course make it clear that effective business communication is a learned skill.

Encouraging and expecting transparent communication is essential when things invariably go wrong. Both reliability professionals and asset managers should feel comfortable and empowered to speak up when they identify and investigate failures or potential issues. Having systems in place for sharing these challenges collaboratively and cooperatively breaks down the silos between teams and builds effective communication.

Transparency can allow the organization to take steps when small problems are identified, preventing them from escalating into larger issues, and allowing for quicker and more effective resolution. Many of us have worked in organizations where issues are hidden until it’s too late, and the amount of effort to do damage control far exceeds the impact of addressing minor concerns early.

Final Thoughts: Why Communication is a Reliability Multiplier

For reliability professionals and asset managers, success is not just about technical expertise or implementing the latest equipment and analytical tools – it’s about effective communication and cooperation between and across teams.

Through cross-departmental collaboration, breaking down silos, and real-time data sharing, a culture of strong and effective communication lays the foundation for solid decision-making, operational efficiency, and overall cost savings. It is key to recognize the importance of clear communication and to encourage an environment where information is freely shared.

Through improved communications, organizations can focus their attention on the areas that matter most. For reliability professionals, this means ensuring that assets deliver performance, unexpected downtime is minimized, and that decisions can be made that drive long-term value and profitability.