In today’s competitive and fast-paced industrial landscape, organizations are increasingly focused on improving the reliability of their assets while minimizing downtime and maximizing performance.

For reliability professionals, continuous improvement isn’t just a buzzword – it’s a strategic approach that helps businesses and municipalities remain efficient, cost-effective, and resilient in the face of evolving challenges and resource constraints. One of the keys to continuous improvement is knowing where to focus improvement efforts.

Assessments turn complexity into clarity – and clarity into action.

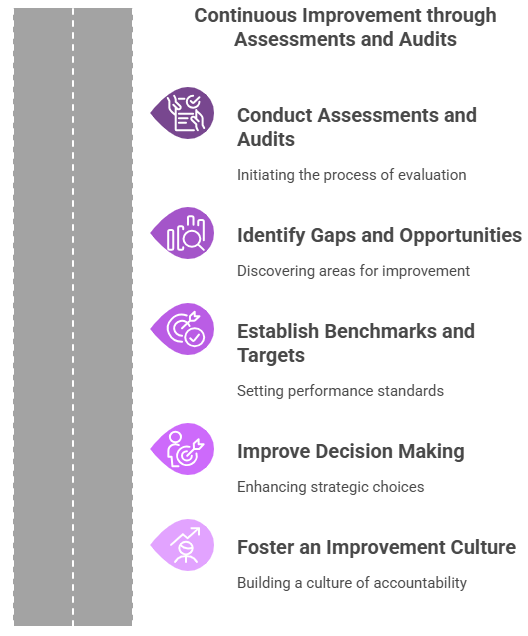

The effective use of assessments and audits is a foundational tool for identifying gaps, pinpointing opportunities for improvement, and ensuring that our reliability practices are aligned with organizational goals, thus driving desired performance.

Understanding Assessments and Audits

While the terms assessment and audit are frequently used interchangeably, they have distinct roles in reliability management and associated continuous improvement efforts.

Assessments

Assessments are the actions or instances of making a judgment about something (Merriam-Webster dictionary). Reliability assessments are specifically aimed at understanding the current state of an asset, process, or system. They focus on identifying strengths, weaknesses, and areas for improvement. Typical reliability assessments may focus on asset condition, performance history, or maintenance strategy effectiveness. Internal or third-party specialists may conduct them.

Audits

Audits, on the other hand, are a formal examination of an organization’s accounts or financial situation (Merriam-Webster dictionary). Reliability audits are structured evaluations that measure compliance with standards, regulations, or internal policies. Reliability audits are typically designed to assess the effectiveness of a program, process, or system in achieving its objectives and extend beyond the financial realm.

A reliability audit might focus on the efficiency of maintenance practices, adherence to the jurisdictional pressure equipment safety protocols (e.g., static equipment asset integrity), the execution of reliability-centered maintenance (RCM) methodologies, or compliance to reliability aspects of ISO 55001, ISO 9001, ISO 14224 or similar standards. Third-party arms’ length auditors more typically perform audits to confirm compliance with external standards.

Both assessments and audits serve as diagnostic tools that enable reliability professionals to make fact-based and data-driven decisions for continuous improvement. The outcomes of the assessments and audits provide valuable insights that help identify areas where corrective actions may be required in a Plan-Do-Check-Act cycle or where best to allocate resources—people and dollars—to improve asset reliability.

Importance of Continuous Improvement

Reliability professionals are essential in industrial sectors such as manufacturing, energy production and distribution, utilities, and transportation, where asset reliability is critical for smooth operations. Their job is to ensure that critical assets are available and deliver the expected performance while reducing unplanned and unscheduled downtime and minimizing the total cost of ownership.

Sustained reliability is built on relentless, strategic refinement.

A mindset of continuous improvement is key to achieving these objectives. It involves a systematic and iterative approach that enhances existing processes, systems, and practices over time.

For reliability professionals, continuous improvement means refining and updating maintenance practices, upgrading systems, and adopting new technologies that can help predict failures before they occur and extend the life of assets.

Reliability professionals do not work alone – their work on continuous improvement is highly integrated with asset managers, operations, maintenance, process safety, operational excellence teams, supply chain management, etc.

How Assessments and Audits Can Drive Continuous Improvement

Identifying Gaps in Current Practices and Processes

One of the outcomes of an assessment or an audit is identifying gaps in current practices and processes compared to the standards or leading practices. Each gap is an opportunity for improvement. Reliability assessments may uncover maintenance strategy inefficiencies, predictive maintenance opportunities, underutilized condition monitoring, or outdated technologies.

Audits may identify where compliance with established standards or leading practices is lacking, leading to suboptimal asset performance.

While we may like to compare ourselves to what are considered ‘best’ practices, it is important to recognize that the goalposts that define ‘best’ are always moving. There is a common expression that ‘yesterday’s excellence is today’s standard and is tomorrow’s mediocrity’ that applies here.

By periodically conducting assessments and audits, reliability professionals can create a plan-do-check-act loop where performance deficiencies and inefficiencies are promptly identified and addressed, leading to incremental improvements that accumulate over time.

Establishing Benchmarks and Targets for Performance

A focus on continuous improvement requires establishing objective benchmarks and reliability metrics, measuring the current baseline performance, and setting targets for improved performance.

The outcomes of reliability-focused assessments will give clear indicators of how well physical assets are performing using metrics such as availability, reliability, uptime, performance, and cost-efficiency.

Metrics make progress measurable – benchmarks make it meaningful.

These metrics can compare past and present performance for the same assets month-over-month or similar assets, such as parallel equipment in the same service. This gives an indication of the impact of implemented improvement initiatives or changes in operating context.

While assessments typically focus on reliability metrics, audits usually focus on whether the organization complies with external or internal reliability standards. This enables reliability specialists to gauge both compliance and effectiveness of current practices to meet these standards. As required, they may adjust maintenance strategies to comply.

Improving Decision Making

Reliability professionals rely heavily on accurate and timely data to make informed and often complex decisions. Regular assessments and audits provide input to this decision-making and future planning. For example, an assessment may identify that enhanced use of predictive analysis or adopting new technology may improve asset condition monitoring and, thus, failure predictions.

At the same time, an audit may point to changes in the external standards or regulations that have not yet been reflected in the maintenance practices and strategies. Combining the insights from both assessments and audits can assist organizations in allocating resources – both people and dollars – to prioritize opportunities for improved outcomes.

A data-driven approach removes the reliance on intuition and increases the likelihood that continuous improvement efforts will result in long-term positive results.

Fostering an Improvement Culture

Assessments and audits can help to foster a culture of accountability and continuous improvement. When they are seen as tools to identify improvement and acted upon, the organizational culture is shaped by this mindset.

Improvement becomes culture when accountability meets data-driven urgency.

Reliability professionals can use the data from assessments and audits to identify and prioritize performance and compliance gaps. Assessments and audits often create a sense of urgency as the organization recognizes the importance of maintaining high standards and holding people accountable for meeting goals.

Adopting leading practices, adherence and compliance to standards, and learning from mistakes promotes a culture of improvement at both the individual and organizational levels.

Putting Audit and Assessment Insights into Action

Assessments and audits for continuous improvement are indispensable for reliability professionals. These tools provide insights into asset performance, highlight areas and opportunities for improvement, and demonstrate how and where reliability practices align with organizational goals.

By using the insights from reliability assessments and audits effectively, organizations can improve their performance, increase equipment availability, and extend the lifecycle of their assets. Assessment and audits allow reliability professionals to stay ahead of the curve in an industrial landscape and competitive market where production efficiency and resilience are key to organizational viability.

Through a culture of continuous improvement, organizations can optimize current operations and position themselves for long-term success. Reliability professionals are well-positioned to contribute to this organizational success.