Atlanta-based consultant Ed Feldman pioneered the concept of guaranteed maintainability. The key to achieving it starts with selecting equipment that functions correctly and is designed for easy, inexpensive, and quick repairs. Maintenance departments can guarantee maintainability by making the right choices from the start.

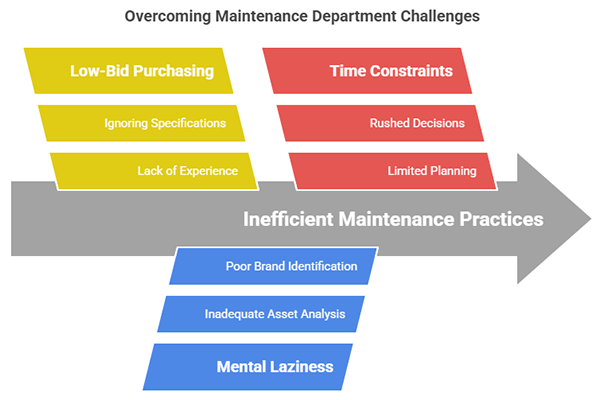

There are three enemies of the maintenance department. First is buying low bid without regard for experience, specification, use, or service; second is mental laziness, where the maintenance people never thought through the performance of the assets and cannot identify the best brands of anything based on accurate data; and the third one is time.

There are nine areas to consider when designing and specifying new assets.

The best way to improve reliability is to choose equipment that doesn’t break down!

It might seem trivial, but the best way to improve reliability is to choose equipment that doesn’t break down! At the very least, select designs that, when they do fail, are easy, inexpensive, and quick to fix. With the right choices in the beginning, maintenance departments can guarantee maintainability.

The maintenance department’s ability to guarantee a plant or facility’s maintainability faces three enemies. The first enemy is buying low bids without regard for experience, specification, use, or service. Low bid specifications are seldom designed to exclude major manufacturers’ models because they haven’t performed well in the past.

The second enemy is mental laziness, in which maintenance, operations, or even engineering never thought through the performance of the assets and cannot identify the best brands of anything based on real data (but they have opinions about everything).

The third enemy is time. Where maintenance has input into the design process, it is usually a one or two-day window, and it might be too late in the design cycle for changes anyway.

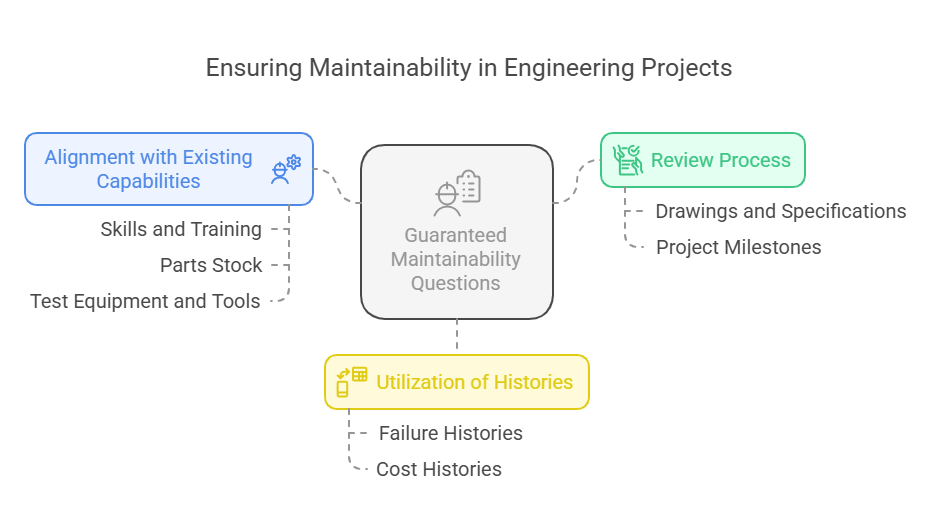

Guaranteed Maintainability Questions

- Are drawings and specifications on all new processes and buildings reviewed by the maintenance department early enough so that changes can be made without adversely impacting the whole project? Some companies give maintenance a look at 30% completion and again at 75% completion of engineering.

- The maintenance department should discuss building specifications and new technologies for machines and building systems to see if they align with existing skills, parts stock, training, and test equipment and tools.

- Are failure and cost histories available to designers or equipment buyers to help them make better decisions? Do they use them?

When designing new plants, machines, or processes, for example, thousands of decisions impact maintainability.

Nine Areas To Consider In The Design And Specification Of New Assets

Access

Some factories are virtual rat’s nests of wires, pipes, ducts, chutes, and machines. Access impacts maintainability. Items that cannot be easily accessed will not be PMed.

If maintenance access is difficult, the work won’t get done—it’s that simple.

In the office of a plant in western Pennsylvania, the HVAC subsystems, including the filter locations, were located on 11′ ceilings above the hallways. The ceilings were drop-in tiles with no catwalks and were filled with wires, pipes, supports, and insulation.

Changing filters and lubricating the units was dangerous, time-consuming, and dirty. One of the rules of guaranteed maintainability is to make needed maintenance easy to perform.

Commissioning and Turnover

How is the asset turned over to the users and the maintenance department? When the asset is contracted for (to build a new building or machine), the purchase documents should spell out the conditions for turnover.

Equipment turnover isn’t just about delivery—it’s about ensuring maintainability from day one.

In a building, the turnover happens when the architect’s punch list is completed. After that, a warranty period starts to allow latent defects to surface. A machine’s turnover might be achieved when the production level reaches an agreed-upon benchmark.

Consider the following as part of your turnover process:

- Documentation in an agreed-upon form is in the hands of the maintenance department.

- Consider videotaping a walk-through with maintenance personnel showing all adjustments, shut-offs, operations, etc.

- Training sessions on or off-site in repair, failure modes, and optimization. Coupons for several future training sessions (we can dream, can’t we?)

Components and Parts

Are the parts needed to service the new asset the same as those already in stock? Secondly, are the parts available from vendors already known to be reliable to your company? When I computerized the delivery of products in an oil terminal, the manager told me that I could use any motor controllers I wanted as long as they were available from Square D. He had existing stock of Square D and a great relationship with the local dealer.

In a subsidized housing development, the contractor submitted (and got approved) specs for an imported furnace equal to the one called for on the drawings. At the time, no spare furnaces or spare parts were bought.

Two years after the property was commissioned, a unit broke down. The wait for parts was 9 months. The management company was forced to refit the apartments with new domestic units as the imported ones broke down.

Design

A manufacturer was having problems with bearing failure. They completed a failure analysis and found that some of the bearings were not getting greased, and others were over-greased. Only one out of three was getting proper greasing.

They installed an automated greasing system and eliminated bearing failure. He has incorporated automated lubrication into his specifications for all new equipment.

Design is the most important single element of reliability.

Design is the most important single element of reliability. It is shocking how many competent manufacturers don’t have reliable data about the failure of the components they rely on. Your CMMS is an excellent data source when the categories are set up correctly and the work orders are filled out and entered accurately.

Documentation

One aspect of guaranteed maintainability is the ability to access vital information when needed. Equipment vendors are notoriously variable in the quality, organization, and usability of their support documentation. See if the vendor maintains an Internet site where you can access technical data, including parts lists and wiring diagrams, and get technical help. Maintenance and repair websites are becoming more common and are a real bonus.

Lucent Technologies (formerly AT&T and, before that, Western Electric) specifies how the manual and support documentation should be constructed in purchase orders for new equipment. This policy is part of their ISO 900X process. Even if you haven’t gone this far, it is important to make sure that the documentation will serve your needs and that you get adequate copies.

They specify the chapters and contents of the manual:

What is the asset? What does it do, including detailed functional specifications? A complete description of how the asset works. What are the components? What should be done if it does not work according to specification (broken up by component)? What are the safety and environmental considerations (how can it hurt me or the environment)?

Installation

When a contractor installs new equipment, they might not consider the long-term need for maintenance (this is one area where close liaison with the contractor that ensures good maintenance techniques and standards are followed is essential).

Simple things like well-positioned shut-off valves, convenient disconnects, and unit orientation to allow easy servicing and positioning of the unit to avoid damage from lift trucks or cranes make a significant difference in your ability to maintain the asset.

Skills Needed to Repair

Whenever you change models or manufacturers, you will encounter a learning curve. It is crucial to evaluate the cost of the learning curve and see if the change in make or model is a justifiable improvement in production levels, reliability, efficiency, or use.

In the absence of a good reason to change, why change? Does the vendor include training and retraining as part of the new equipment package?

Surfaces/Finishes

This is very important for buildings and parts of machines that come in contact with the product. Some surfaces are better (last longer, are easier to clean, etc.) than others.

Rutgers University in New Brunswick, New Jersey, specified a solid surface material such as Corian© in the dorm bathrooms instead of tile. Solid surface material is more expensive but almost un-damageable (and it can be repaired if damaged).

Tools

Do you have the specialized tools needed to service this new type of asset? How much money will need to be spent on new tools? If a new class of asset is chosen, ensure the new tools are included in the budget and acquired.

Guaranteed Maintainability Has Other Important Aspects

- Maintenance and operators need to know how to operate the equipment. At GE Engineered Plastics, the maintenance department personnel were certified operators at the plant.

- Unfortunately, many maintenance professionals do not have good networks of maintenance people in other A well-cultivated network can provide product intelligence, repair experience, and re-engineering tips.

- If your business depends on a manufacturer’s equipment, visit the factory where the asset was built. Meet behind-the-scenes engineers and shop people. These people can become a great resource. Be sure to let them know how necessary their equipment is to your operation. Bring pictures of their ‘babies’ that you put to work.

- When buying new equipment, use the complete life cycle cost rather than the purchase price as the cost basis. Look at your operation, see how you need the asset to be used, try to imagine future uses and capacity needs, and pick based on the complete picture. Assets should be purchased for the present value of their cost stream divided by the estimated output rather than just the acquisition price divided by the production.

- Guaranteed maintainability requires experiments in new types of assets, new techniques, and new materials.

Good luck with this!