An effective mechanical maintenance supervisor oversees daily team activities to ensure safe and efficient equipment operation. Responsibilities include preventive maintenance planning, repair management, inspections, staff training, safety compliance, and budget control.

Maintenance Supervisors Follow the 11 Leadership Principles

- Lead by example

- Know yourself and seek improvement

- Become an expert in proactive maintenance

- Manage with leading and lagging metrics for all maintenance processes from PM to failure reporting

- Be 100% competent in your CMMS

- Treat everyone as your equal, demonstrate respect, and always be humble to everyone in all situations

- Know your Maintenance Technicians by name and listen to any concerns they may want to tell you

- Know each Maintenance Planner by name and check on them, occasionally asking, “How can I help you?”

- Take time to talk to your employees if they ask for your time

- Never ask anyone to do something you would not do yourself

- Become true partners with Production Leadership at all levels

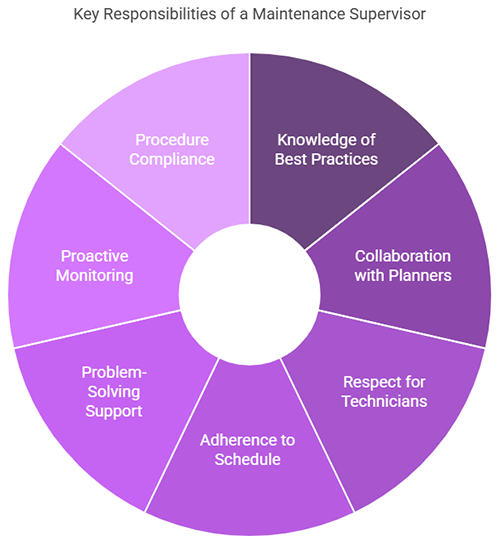

Attributes of a Maintenance Supervisor

- Knowledgeable of Maintenance and Reliability Best Practices and Demonstrates this Knowledge Every Day

- Works with Maintenance Planner to ensure the Maintenance Schedule is obtainable

- Respects all Maintenance Technicians and takes time to listen to them if they have a problem

- Ensures Maintenance Technicians are following the Maintenance Schedule

- If a Technician is having a problem, the supervisor will take time to help them solve the problem

- Makes rounds to see if any technician is having a problem to help them resolve the problem

- Ensures Maintenance Technicians are following procedures

Key Responsibilities

Leadership and Team Management

- Leading and motivating a team of mechanical maintenance technicians.

- Assigning work tasks and managing schedules.

- Providing training and development opportunities for staff.

- Evaluating employee performance and addressing performance issues.

Maintenance Planning and Execution

- Developing and implementing comprehensive preventive maintenance programs.

- Scheduling and prioritizing maintenance tasks with the Maintenance Planner.

- Responding to emergency maintenance requests.

- Monitoring equipment performance and identifying potential issues.

Inspection and Troubleshooting

- Conducting regular equipment inspections to identify wear and tear.

- Diagnosing mechanical and electrical faults and troubleshooting issues.

- Overseeing repairs and ensuring proper completion.

Safety Compliance

- Enforcing all safety regulations and procedures.

- Conducting safety training for maintenance personnel.

- Investigating safety incidents and implementing corrective actions.

A maintenance supervisor should possess strong leadership skills, technical expertise in building systems, excellent communication abilities, problem-solving skills, organizational capabilities, budget management proficiency, and the ability to prioritize workloads to effectively oversee a team of maintenance technicians and ensure smooth operations within a plant.

Reporting and Documentation

- Maintaining detailed maintenance records and work orders.

- Generating reports on equipment performance and maintenance activities.

- Communicating maintenance status updates to relevant stakeholders.

Vendor Management

- Selecting and managing external maintenance contractors.

- Negotiating contracts and pricing with vendors.

Essential Skills for a Mechanical Maintenance Supervisor

- Technical Expertise: Strong understanding of mechanical systems, equipment operation, and troubleshooting techniques.

- Leadership Skills: Ability to motivate and manage a team effectively.

- Problem-solving skills: Identifying root causes of issues and developing solutions.

- Analytical Skills: Analyzing data to identify trends and make informed decisions.

- Communication Skills: Clearly communicating with technicians, management, and other departments.

- Safety Awareness: Commitment to maintaining a safe working environment.

Maintenance Supervisor Job Description

We are seeking a driven and detail-oriented Maintenance Supervisor to oversee our maintenance operations. The ideal candidate will manage maintenance staff and ensure that all industry standards and safety regulations are adhered to.

This role requires expertise in overseeing routine and preventative maintenance of equipment and systems, making it crucial for reducing downtime and enhancing operational efficiency.

Responsibilities

- Oversee and coordinate the daily work activities of the maintenance team.

- Develop and implement maintenance procedures and ensure implementation of the same.

- Maintain all oil and gas equipment and systems to ensure maximum efficiency.

- Ensure compliance with all safety and environmental regulations.

- Prepare and control annual budget for maintenance projects.

- Schedule and supervise maintenance repair jobs and contractors.

- Conduct regular inspections and assessments to identify necessary repairs and replacements.

- Lead, train, and mentor maintenance personnel and evaluate their performance.

Requirements

- Proven experience as a Maintenance Supervisor in the Oil & Gas sector (minimum X amount of years).

- Familiarity with regulatory, safety, and environmental standards in the industry.

- Strong knowledge of maintenance machinery and equipment.

- Excellent leadership and managerial skills.

- Ability to plan, schedule, and oversee maintenance operations.

- Hold an “Associate’s Degree.”

- Excellent communication and interpersonal skills.

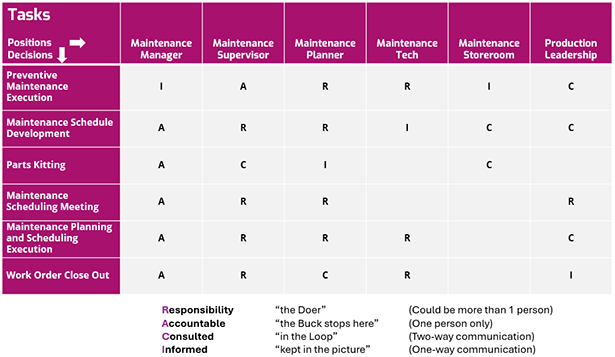

Maintenance Supervisor RACI

Maintenance Supervisor follows the RACI Chart to ensure their tasks are completed to specifications.