Understanding gear fatigue failures begins with mastering the fundamentals of how materials behave under stress. When mechanical components like gears face repeated cycles of loading and unloading, they can develop subtle signs of deterioration long before catastrophic failure occurs.

Before we dive into specific gear failure patterns, let’s review the essential principles of component fatigue that form the foundation of all fatigue-related failures.

- Fatigue occurs when a material is subjected to repeated loading and unloading.

- When the loads are above a certain threshold, microscopic cracks will begin to form at a material’s surface.

- Cracks always begin in highly stressed areas of a material.

- Eventually, a crack will reach a critical size, and the structure will suddenly fracture.

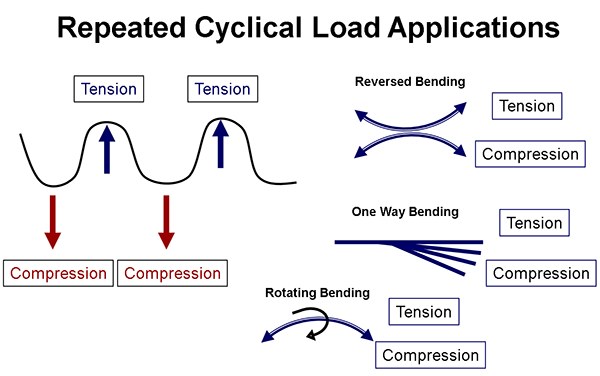

My prior article on component fatigue discussed the various cyclical loading applications. Let’s review them again with this graphic.

While these general fatigue principles apply broadly, gears exhibit distinct failure characteristics that provide crucial clues about their service history and failure modes. Some of these basics are:

- They always have an origin(s)

- Progression marks may be visually present (depending on load variations)

- They will have a Final Fracture Zone (FFZ)

- Ratchet marks may be present

- Spalls (or Hertzian Fatigue) may be present

- Electrical fluting may be present

- Evidence of inadequate lubrication may be present

Let’s review some failed parts and see if we can associate these characteristics with them.

This gear is heavily damaged at the addendum or top. The origin is Hertzian (beneath the surface, working outward). The failure will be rapid once the wear is through the case-hardened area.

Associated Characteristics

- Always have an origin(s)

- Spalls (Hertzian Fatigue) may be present (bearings)

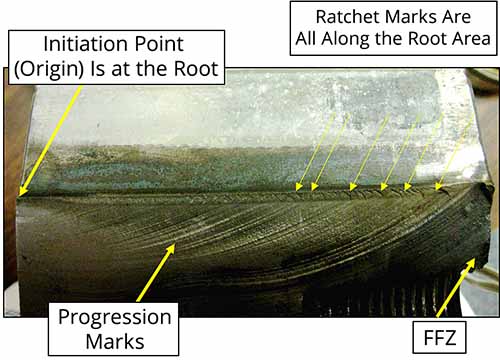

This crack was initiated in the gear root and was under normal loads.

Associated Characteristics

- Always have an origin(s)

- Progression marks may be visually present (depends on load variations)

- Will have a Final Fracture Zone (FFZ)

- Ratchet marks may be present

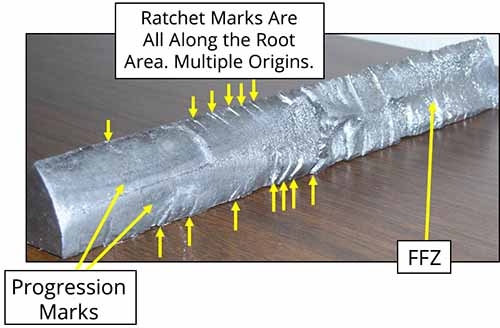

The crack was initiated in the gear root and was under heavy loads because of the large FFZ.

Associated Characteristics

- Always have an origin(s)

- Progression marks may be visually present (depends on load variations)

- Will have a Final Fracture Zone (FFZ)

- Ratchet marks may be present

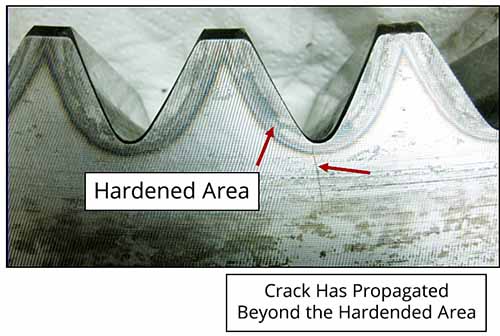

The crack was initiated in the gear root where the stresses are high.

Associated Characteristics

- Always have an origin(s)

This gear is damaged at the addendum or top. The origin is Hertzian (beneath the surface, working outward). This defect is often a result of misalignment.

Associated Characteristics

- Always have an origin(s)

- Spalls (Hertzian Fatigue) may be present (bearings)

This gear is damaged at the addendum or top. The origin is Hertzian (beneath the surface, working outward). This defect is often a result of misalignment.

Associated Characteristics

- Always have an origin(s)

- Spalls (Hertzian Fatigue) may be present (bearings)

As an FYI, as usual, I am pulling all of this material from our public workshops. These workshops appeal to the novice and the more seasoned investigators who want to learn more about the physics of failure, recognize common failure patterns, and understand how those patterns came to form.