The CMRP is the only certification program of its kind accredited by the American National Standards Institute (ANSI), which follows the globally recognized ISO standards for its accreditation purposes. The test thoroughly examines a broad scope of expertise measured against the universal standard.

“If a step in a process is skipped or performed at a substandard level, it creates defects known as failures.” – Ron Thomas, Former Engineering/Maintenance Manager Dofasco Steel

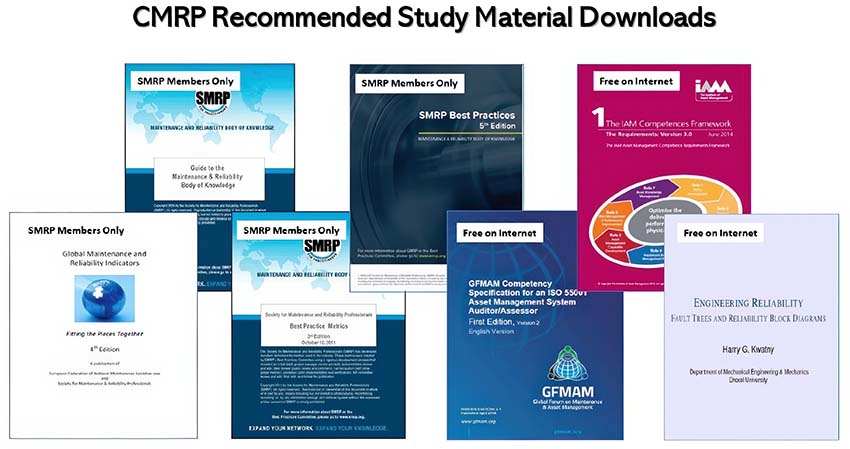

One must have “Knowledge” concerning the following:

- Known Maintenance and Reliability Best Practices

- SMRP Body of Knowledge

- SMRP Metrics Definitions

- SMRP Best Practices

- SMRP Global Maintenance and Reliability Indicators

- GFMAM Asset Management Landscape

- IAM Competency Framework

- Engineering Reliability Fault Trees and Reliability Block Diagrams by Harry G. Kwatny

- ADKAR (Book) A Model for Change in Business, Government, and Our Community

Recommendations

Step 1 – Join SMRP (https://smrp.org)

Step 2 – Join one of the SMRP Chapters or Special Interest Groups and Participate, meet others and learn from each other

Step 3 – Purchase and Study “Maintenance Best Practices” by Ramesh Gulati and “Rules of Thumb for Maintenance and Reliability Engineers” by Ricky Smith and Keith Mobley, ADKAR- a MODEL FOR CHANGE

Step 4 – Take training in “SMRP Body of Knowledge” (not a requirement)

Step 5 – Download and Study the following from SMRP Website as a member. (SMRP Body of Knowledge, SMRP Metrics, and SMRP Best Practices, Global Maintenance and Reliability Indicators)

Step 6 – Take the practice exam in “Maintenance Best Practices” by Ramesh Gulati, you may not see any of these questions on the exam however it will help you understand how the questions are asked, great practice. Each question is linked to a page in this book to study.

Study the SMRP Body of Knowledge (5 Pillars)

Pillar 1: Business & Management

This subject area describes the skills used to translate an organization’s business goals into appropriate maintenance and reliability goals that support and contribute to the organization’s business results.

Pillar 2: Manufacturing Process Reliability

This subject area relates maintenance and reliability activities to the organization’s manufacturing process to ensure that they improve the manufacturing process.

Pillar 3: Equipment Reliability

This subject area describes two activities that apply to the equipment and processes for which the maintenance and reliability professional is accountable. First, are those activities used to assess the current capabilities of the equipment and processes in terms of reliability, availability, maintainability, and criticality. Second, are the activities used to select and apply the most appropriate maintenance practices so that the equipment and processes continue to deliver their intended capabilities most safely and cost-effectively.

Pillar 4: Organization & Leadership

This subject area describes processes for assuring that the maintenance and reliability staff is the most qualified and best assigned to achieve the maintenance and reliability organization goals.

Pillar 5: Work Management

This subject area focuses on the skills used to perform maintenance and reliability work. It includes scheduling and planning activities, quality assurance of maintenance activities, stores, and inventory management.

Think about how you could use the 5 Pillars to Optimize/Reshape your current Maintenance and Reliability organization.

Study SMRP Metrics

Review the definitions of each metric and consider how these metrics could be used to optimize one’s current metrics.

The SMRP Metrics allow the maintenance and reliability professional to measure performance consistently, make valid comparisons, establish achievable goals and objectives, and set realistic expectations. Standardizing how our maintenance and reliability practices are measured forms the foundation for these goals.

Remember this:

- Leading Metrics lead to results

- Lagging Metrics are the results

Study SMRP Best Practices

SMRP Best Practices is a comprehensive publication of world-class metrics, guidelines, and a glossary of terms for the maintenance, reliability, and physical asset management profession.

This publication is designed to help practitioners run safe, cost-efficient, and effective maintenance and reliability programs that align with an organization’s strategic, operational, and tactical best practices.

The 70+ metrics and guidelines in this new edition provide standardization and benchmarks to measure the success of maintenance and reliability programs.

Each metric is broken down by definition, objective(s), formula, component definitions, and qualifications and includes a sample calculation, best-in-class target values, cautions, and notes for harmonization. The guidelines provide additional information and further clarification of component terms used in SMRP’s metrics.

On the Day Before the CMRP Exam

Things to Do

- Minimize alcohol intake.

- Study 2-4 hours every other day using the material recommended above

- Study – take a 30-minute break every hour, walk around outside, and clear your head; no TV while studying.

- Study with someone else is good.

- Get plenty of uninterrupted sleep (minimum of 6 hours)

Things Not to Do

- Purchase an APP with CMRP Questions, NEVER Works

- Purchase a CMRP Study Book, wasting your time.