The failure occurred in a turbine-driven boiler feedwater pump (TDBFP) at a fossil fuel power plant. Specifically, the outboard boiler feed pump unexpectedly shut down while the plant was operating under normal conditions, leading to a forced outage.

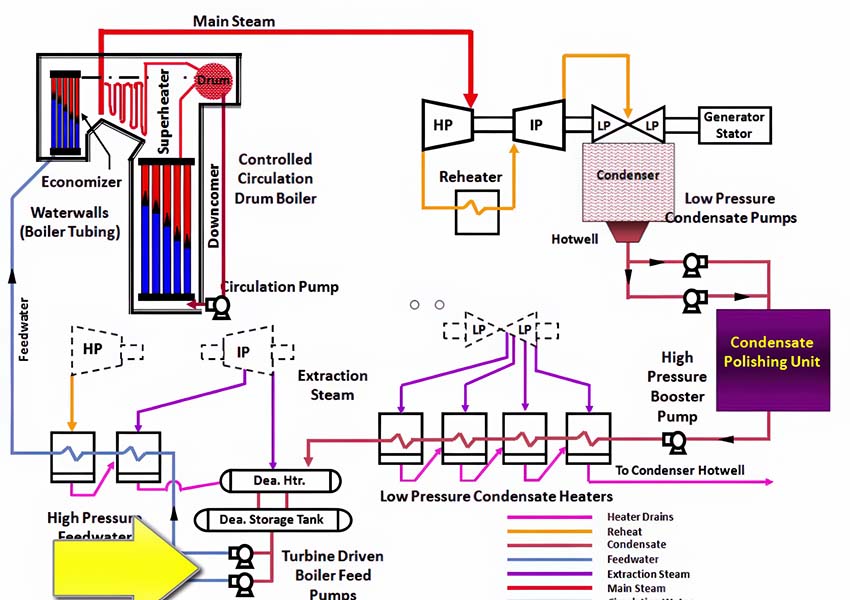

Here is a basic process flow diagram for this process:

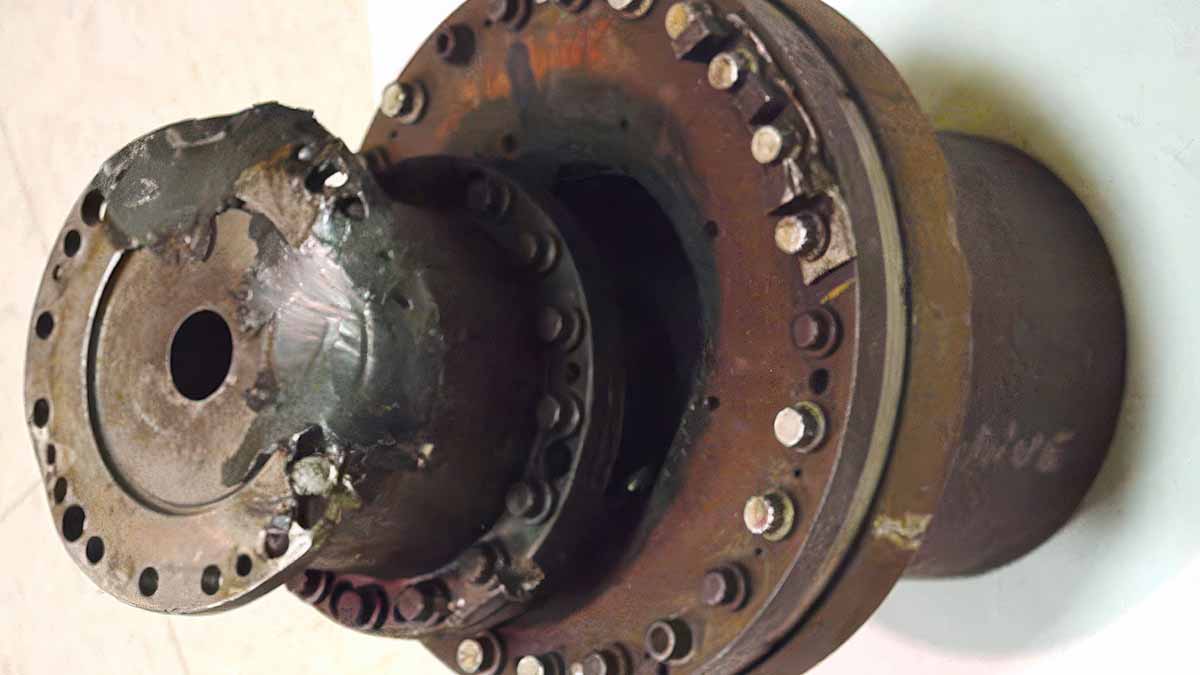

When investigators were able to access the failed components safely, the following was found:

- All inboard components are detached (see below)

- The pump had lift and could be rotated by hand

- The strainer was not in place

- The turbine-driven boiler feedwater pump (TDBFP) opened, and no damage was evident (including no damage to the impeller and/or housing)

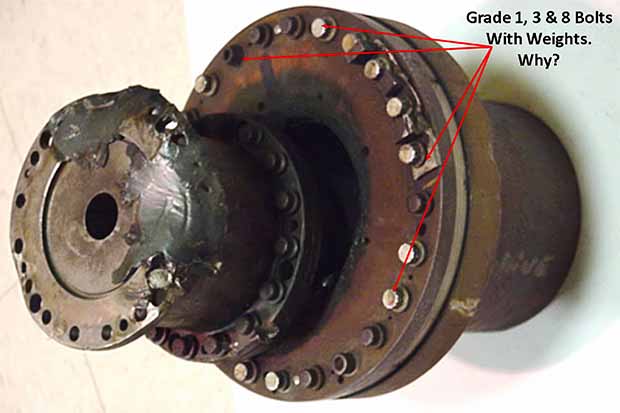

Given the limited preliminary physical data, what anomalies do we see that need explanation? Why were there different grade bolts and balancing weights on the coupling?

Here is the summary path(s) to failure.

- ‘Procedure/specs for coupling fasteners were inadequate’ & ‘No QC inspection required during installation/repair’ [Latent Root Causes/Organizational System Related] >

- Results in ‘Field Selection Error’ when retrieving replacement coupling bolts [Human Root Cause/Decision Error Related] >

- Results in wrong bolts installed in the coupling [Physical Root Cause] >

- Results in inappropriate bolt coming loose and locking up turning gear>

- Results in pump being overloaded>

- Results in coupling failing>

- Results in pump failing to act as a primary mover>

- Results in turbine-driven boiler feed pump to shut down in operation>

- 9. Results in plant tripping due to loss of boiler feed water

This is a summary of one of the many paths to failure. If you want to receive a copy of the entire Logic Tree, contact us, and in ADDITIONAL COMMENTS, just type ‘BFWP RCA’ and we’ll know what you mean. Also, to discuss our extensive Root Cause Analysis training and software (online and offline), type “RCA Stuff’. I guarantee a human will read and respond within 24 hours 😊!