Equipment failures aren’t random. They stem from specific, avoidable issues that often go unnoticed until it’s too late. This article lists the top five reasons companies face costly downtime and provides actionable solutions to build a more proactive maintenance strategy.

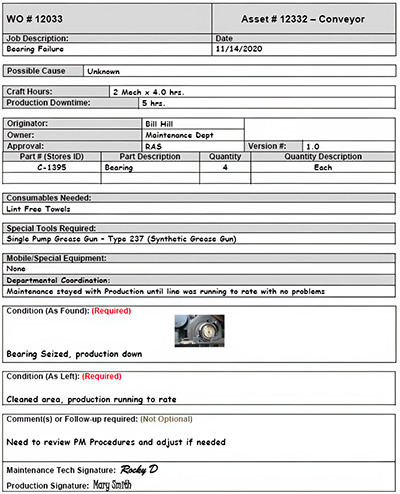

Reason 1: Work Orders Fail to Capture All Emergency Work

Work orders do not capture all emergency work. Many companies have rules such as, “A work order will be written only if the equipment is down for more than one hour.” This rule does not make sense. For example, a circuit overload on a piece of equipment trips 15 times a month. Minor problems often lead to major equipment failure, but no one knows this is occurring.

Solution: “ALL” Maintenance work/actions must be tracked with a work order assigned to a specific asset.

Reason 2: Missing Assets in the CMMS/EAM Block Accurate Tracking

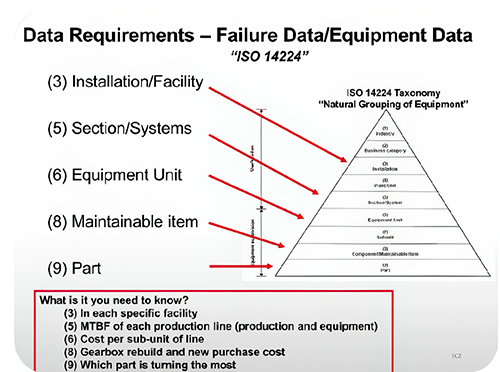

Not every asset is loaded into the CMMS/EAM. This problem makes writing an emergency work order impossible. If you are not tracking every asset down to the component level, you cannot possibly identify any true reliability issue.

Think about it this way: if 20% of your assets eat up 80% of your resources, wouldn’t you want to identify that 20%, the bad actors? Ensure all your assets in your CMMS/EAM, track the MTBF, and the bad actors will become apparent.

Asset Hierarchy is critical to managing equipment reliability and mitigating failures using ISO 14224.

Solution: Walk down your assets and identify

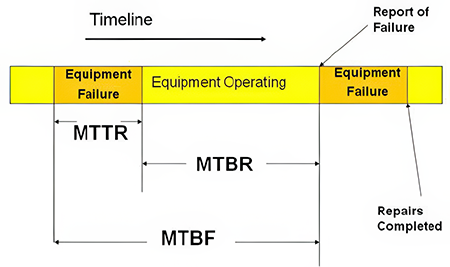

Reason 3: Skipping MTBF Metrics Creates Blind Spots in Reliability

It isn’t vital to measure MTBF because other metrics provide equivalent value. You can get asset reliability from different metrics, but keep it simple using MTBF.

Count the number of breakdowns (the number of emergency work orders) for an asset during a given time interval. That is all it takes to learn how long the equipment runs (on average) before it fails.

Reason 4: Reactive Maintenance Prevents Focus on Reliability Metrics

The maintenance organization is so reactive that there’s no time to generate any metrics. They are constantly scrambling merely to react to the latest crisis. However, taking a small step in the right direction — tracking just one measure of reliability — will reveal 20% of the assets burning 80% of the resources. If you start with the worst actor, you will be surprised at how quickly you can rise out of the reactivity quagmire.

For example, a plant manager who recently measured the MTBF for what he called his “Top 10 Critical Assets” was shocked at the results. He expected the combined MTBF for these assets would be around eight to nine hours. In the first month of this initiative, he found that the actual MTBF was 0.7 hours. You may find yourself in the same situation. You will never know the true reliability status on your plant floor until you begin measuring it.

Reason 5: Overwhelming Problems Hinder a Reliability-Focused Culture

There are too many other problems to worry about right now without being pressured to measure reliability, too. I have heard this many times, and it tells me that the organization is in total reactive mode. This organization deals only with the problem of the hour.

If 20% of your assets are taking 80% of your resources, dig yourself out of the problem by attacking the assets that cause the most pain. These high-payoff assets will respond to a reliability improvement initiative. We have got to stop fighting fires. The characteristics of adept firefighters include:

- High turnover of personnel (mostly in production)

- Maintenance costs that continue to rise.

- Maintenance costs that are capped before the month ends (“Don’t spend any more money this month; We’re over budget)

- Every day is a new day of problems and chaos.

- Maintenance is blamed for missing the production goals.

Fighting fires and initiating reliability improvement simultaneously is difficult, but it can be done. Start measuring MTBF and attack the high-payoff assets (top 20%). You cannot change a company’s culture from reactive to proactive overnight, but you can eliminate reliability problems one major system at a time. That is where you will find a rapid return on investment. Change people’s activities and behaviors slowly, and you will transition to a proactive culture.

Asset reliability is the key to keeping a company profitable, increasing its capacity, and reducing maintenance costs.