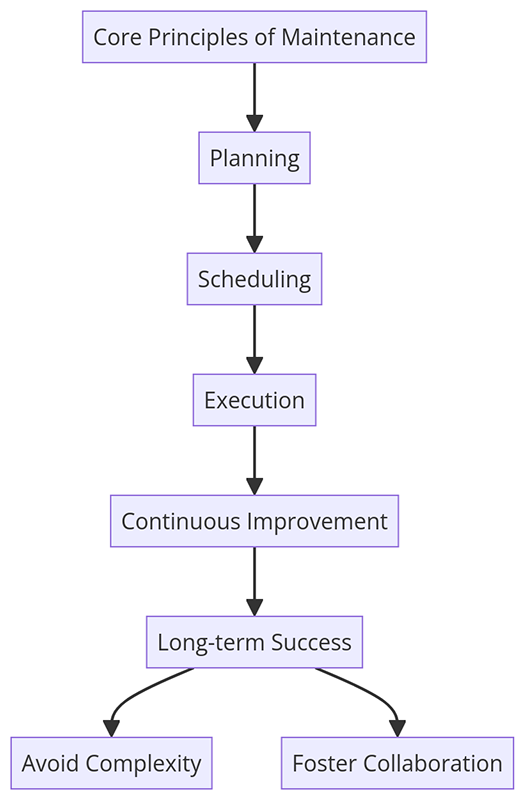

In this video, Christer Idhammar from IDCON discusses the role of simplicity in reliability and maintenance management. He highlights how avoiding unnecessary complexity and focusing on fundamental practices can lead to more consistent and effective maintenance programs, ultimately driving long-term success in industrial operations.

Quick Takes

- Importance of Simplicity in Reliability Management: Christer Idhammar emphasizes keeping reliability and maintenance processes straightforward to achieve sustainable results.

- Confusion with New Terminologies: The frequent introduction of new terminologies and systems leads to confusion and hinders long-term success.

- Consistency and Long-Term Focus: Organizations should focus on consistent and long-term application of best practices rather than constantly switching between different approaches.

- Tools vs. Systems: It’s crucial to distinguish between tools (like RCM and Six Sigma) and systems to avoid confusion and to ensure they are integrated effectively.

- Collaboration between Operations and Maintenance: Effective maintenance requires close collaboration between operations and maintenance to ensure reliable production.

- Cultural and Organizational Challenges: Different industries and cultures face unique challenges, but the fundamental maintenance and reliability processes remain consistent across sectors.

By the Numbers

- 67% of plants have had more than three plant managers in the last 10 years, leading to frequent changes in management and potential disruptions in maintenance strategies.

- 90% of the effort to improve maintenance is about managing people, while only 10% is technology.

- 50% of all reactive maintenance is due to improper prioritization by operations, showing the need for better planning and scheduling.

Visualized