Planned Maintenance Percentage (PMP) is a metric used in maintenance management to evaluate the effectiveness of a maintenance program. It measures the proportion of maintenance work that is planned versus reactive. Specifically, it shows you how much of your maintenance is scheduled and controlled instead of being done in response to unexpected breakdowns or emergencies.

A Cooking Analogy for PMP

Think of a factory as a kitchen. In this kitchen, a chef wants to prepare meals (keep the equipment running smoothly). There are two types of cooking: planned cooking and emergency cooking.

- Planned Cooking involves prepping your ingredients ahead of time, setting aside time to cook each meal, and ensuring that all your tools (pans, knives, etc.) are ready to go. You follow a recipe, work at a steady pace, and know exactly what you need to do next.

- Emergency Cooking happens when a guest unexpectedly arrives, and you have to scramble to find ingredients and tools and cook something quickly without a plan. You might burn something, forget an ingredient, or make a mess because you’re rushed and unprepared.

In the maintenance world, planned maintenance is like planned cooking—everything is scheduled, and you know exactly what needs to be done. Reactive maintenance is like emergency cooking—everything is done in a hurry because something has already gone wrong.

The Planned Maintenance Percentage Formula

Planned Maintenance Percentage is calculated using the following formula:

![]()

Where:

- Total Hours of Planned Maintenance: Includes all the hours spent on preventive, scheduled, or predictive maintenance tasks.

- Total Maintenance Hours: The sum of all maintenance hours, including planned and reactive (unplanned) maintenance.

Planned Maintenance Percentage Example Calculation

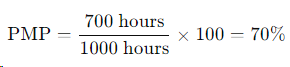

Suppose a factory has 1,000 total maintenance hours in a month. Out of these, 700 hours are spent on planned maintenance, and 300 hours are on reactive maintenance.

Using the formula:

This means that 70% of the maintenance work is planned, and 30% is reactive.

Why PMP Matters

- Efficiency: A higher PMP indicates that most of your maintenance work is planned, leading to fewer unexpected breakdowns, better resource management, and smoother operations.

- Cost Savings: Planned maintenance is typically less expensive than reactive maintenance because you can schedule it during downtime, avoid costly emergency repairs, and extend the life of the equipment.

- Reliability: Equipment is more reliable when regularly maintained according to a plan, reducing the risk of unexpected failures.

How PMP Reflects Order or Disorder

If your PMP is low (say 40%), it indicates that most of your maintenance is reactive. This might be like constantly dealing with surprise guests in your kitchen—you’re continually stressed, things often go wrong, and the quality of your meals (operations) suffers.

On the other hand, a high PMP (like 80% or more) means you’re mostly following a well-thought-out plan. Your kitchen runs smoothly, meals are prepared on time, and you rarely have to deal with chaos. In a factory, this translates to fewer breakdowns, lower costs, and more predictable operations.