The Robot Utilization Rate is a key performance metric used in manufacturing and automation to measure the efficiency and productivity of robotic systems. It tells us how much time a robot is actively working compared to its available operational time. In simpler terms, it helps us understand how well we’re using our robots.

Breaking It Down

Imagine you run an automotive manufacturing plant and have invested in a state-of-the-art robotic arm (let’s call it AutoBot) that can assemble car parts without any human intervention. You bought this expensive robot to boost your plant’s productivity, but just purchasing it isn’t enough; you also want to ensure it’s being used efficiently.

Now, let’s say your manufacturing plant operates for 10 hours a day. If AutoBot assembles car parts for only 5 of those 10 hours and sits idle or undergoes maintenance for the remaining 5 hours, its utilization rate is 50%.

This is the core idea behind the Robot Utilization Rate: it measures how much of the robot’s potential is used for productive work.

Robot Utilization Rate Technical Definition

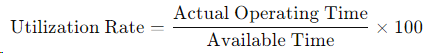

The Robot Utilization Rate is typically calculated using the following formula:

- Actual Operating Time: This is the total time the robot spends performing productive tasks (like assembling parts, welding, or packing items).

- Available Time: This is the total time the robot could have been operating, including when the factory is open, or the robot is powered on and ready to work.

Factors Affecting Utilization Rate

Several factors can influence the Robot Utilization Rate:

- Downtime: If the robot is frequently stopped for maintenance, repairs, or programming updates, the utilization rate drops.

- Bottlenecks: If other processes slow the workflow, the robot might have to wait, reducing its utilization rate.

- Idle Time: If the robot isn’t given enough tasks or is waiting for materials, it’s not being used to its full potential.

Importance of Utilization Rate

The utilization rate is important because it directly relates to productivity and return on investment (ROI). A low utilization rate might suggest that the robot is underused, which could mean that the company isn’t getting the most value out of its investment. On the other hand, a high utilization rate typically indicates that the robot is well-integrated into the production process and contributes effectively to the company’s output.

A Deeper Dive: Balancing Utilization and Longevity

While aiming for a 100% utilization rate might seem ideal, this isn’t always practical. Just like running a car engine at full throttle all the time wears it out faster, continuously operating a robot at full capacity without breaks for maintenance can reduce its lifespan and increase the risk of breakdowns. Therefore, balancing a high utilization rate with adequate maintenance and downtime is crucial.

Robot Utilization Rate Real-World Example

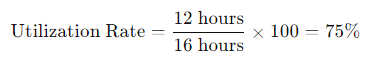

Consider an automotive assembly line where robots are used for tasks like welding, painting, and assembling parts. If a robot in this setting has an available time of 16 hours per day (assuming two shifts) but is only active for 12 hours due to waiting for parts or reprogramming, its utilization rate would be:

This tells the plant manager that there’s a 25% gap where the robot could potentially be more productive, which could lead to a review of processes to optimize performance.

The Robot Utilization Rate is a straightforward but powerful metric that provides insight into how effectively a robotic system is used.