Hydraulic fluid selection has always mattered. But in today’s industrial landscape—where environmental performance, cost per ton, and asset availability are under simultaneous pressure—it matters more than ever. The stakes are high, and the margins for error are small.

The wrong fluid quietly erodes reliability—until it loudly fails your system, your budget, and your ESG goals.

After more than 30 years in reliability engineering, I’ve seen firsthand the consequences of poor fluid performance: failed pumps, varnished valves, fouled filters, and unplanned downtime that ripples through operations. I’ve also seen the missed opportunities when maintenance strategies don’t evolve alongside environmental priorities.

I co-founded the Noria Corporation and the International Council for Machinery Lubrication to elevate lubrication to its rightful place in reliability discussions. I later pursued a master’s in sustainability from Harvard to help bridge the technical with the environmental.

Recently, a new generation of lubricants has entered the market that delivers both true biodegradability and high-performance characteristics. These formulations span a range of applications, including hydraulic oil, engine oil, and bearing and gear oils.

For the purposes of this article, we’ll focus specifically on hydraulic fluid as our working example, where the impact of performance, sustainability, and service life is particularly critical.

The Ester Problem: Where “Green” Fluids Fail in Practice

Most biodegradable hydraulic fluids on the market today are ester-based. These fluids satisfy biodegradability requirements, but they often fall short in demanding service environments. The failure mechanism is well understood: hydrolysis.

In ester molecules, the chemical bond between the acid and alcohol components is highly susceptible to attack by water. When moisture enters the hydraulic reservoir—and it always does, through condensation, breathing, or maintenance exposure—hydrolysis begins. This reaction cleaves the ester molecule, producing free acids and alcohols.

The result?

- Increased total acid number (TAN), which accelerates corrosion of internal surfaces

- Decreased viscosity and lubricity, leading to metal-on-metal contact

- Sludge and varnish formation, particularly around servo valves and tight-clearance controls

- Seal degradation, as the byproducts are often incompatible with common elastomers

- Shortened fluid life, requiring early replacement and greater waste volume

This is not hypothetical. It’s observable failure that leads to measurable cost.

Operators often purchase ester-based fluids to meet regulatory or permitting requirements for biodegradability. But the price they pay in system reliability—and the total cost of ownership—is rarely made clear. In some systems, fluid changes may occur as often as every 1,000–1,500 hours just to stay ahead of the acid number curve.

That’s not sustainable. And it’s certainly not precision maintenance.

A Better Chemistry: Hydrocarbon-Based Biodegradability

Next-generation hydraulic fluids break this cycle by offering readily biodegradable performance without relying on ester chemistry. Developed through advanced hydrocarbon formulations, these fluids maintain oxidative stability and water tolerance under harsh conditions. They meet OECD 301 biodegradability requirements but perform more like high-spec Group II+ or III+ base oils.

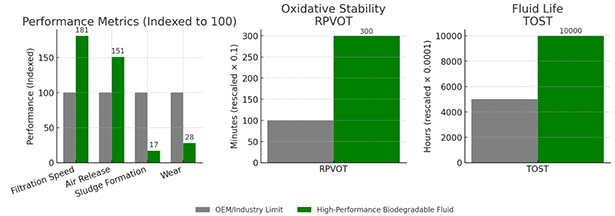

Key technical advantages include (Figure 1):

- No ester bonds to hydrolyze, eliminating TAN creep over time

- Stable kinematic viscosity across the service interval

- Exceptional oxidative stability, measured via industry-standard RPVOT and TOST methods

- Low foaming tendency and fast air release, improving control stability

- Minimal sludge formation, verified through standardized testing

Figure 1 – High-performance biodegradable fluid delivers faster filtration, lower sludge and wear, and improved air release compared to OEM and industry limits.

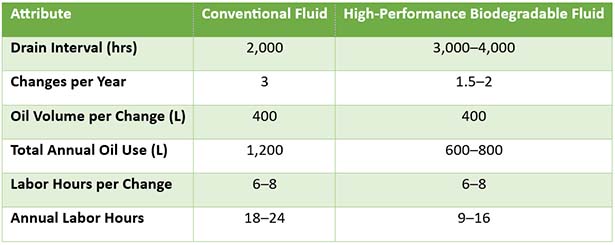

In standard Turbine Oil Oxidation Stability Test (TOST) analysis (ASTM D943), these fluids often exceed 10,000 hours. In Rotating Pressure Vessel Oxidation Test (RPVOT) analysis (ASTM D2272), oxidative resistance commonly exceeds 300 minutes, placing them among the upper echelon of premium hydraulic fluids. These metrics are indicators of fluid life but also correlate strongly with predictable viscosity, low varnish risk, and filter integrity over time (Figure 2).

Figure 2 – High-performance biodegradable hydraulic fluid outperforms OEM requirements on essential measures.

In other words, they run clean and they last longer, without compromising environmental goals.

Field Application: Mining Haul Truck Hydraulics

Let’s bring this into context with a typical asset.

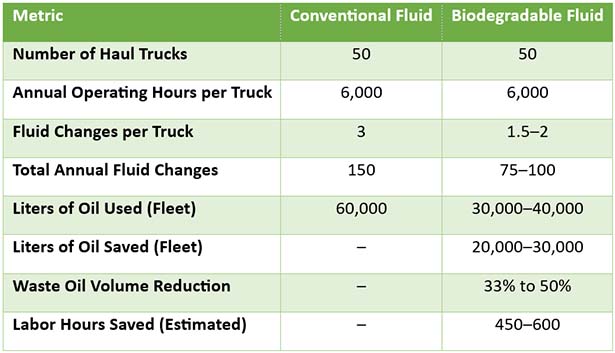

A Caterpillar 793F or Komatsu 930E haul truck runs around 6,000 hours per year in most mining operations. OEM guidance and common practice suggest a hydraulic fluid drain interval of around 2,000 hours, assuming a conventional mineral-based fluid. That equates to three full changes annually.

Each oil change includes:

- 300–500 Liters of hydraulic fluid

- 6 to 8 labor hours, depending on setup and accessibility

- Downtime and risk coordination for tagout, access, and containment

- Filter changes and oil waste disposal logistics

- Spill prevention and environmental controls

With the improved stability and oxidative life of advanced biodegradable fluids, most operations will safely extend to 3,000 or even 4,000 hours between changes. That translates to just 1.5 to 2 changes annually—a significant operational gain.

Beyond the raw savings in fluid and labor, fewer oil changes mean:

- Fewer technician interventions (lower exposure risk)

- Reduced risk of contamination during changeouts

- Lower likelihood of startup instability after maintenance events

The fluid’s exceptional demulsibility also ensures that if water does enter the system, it will readily separate and can be removed through standard offline filtration or sump drainage. This translates into measurable economic benefits (Table 1).

Maintenance Comparison – Single Haul Truck:

Table 1 – Lube maintenance comparison between a conventional fluid and a high-performance biodegradable fluid – single haul truck.

Economic Impact at Fleet Scale:

The benefits multiply quickly at the fleet level. Consider a fleet of 50 trucks in a large surface mining operation (Table 2). By switching to a high-performance biodegradable fluid and extending drain intervals to 3,000–4,000 hours:

Fleet Impact Summary – Conventional vs. High-Performance Fluids

Table 2 – The same comparison expanded to a fleet of 50 haul trucks.

These numbers don’t just look good on a PowerPoint—they influence cost per ton, asset availability, and budgetary planning.

In an environment where reliability and sustainability often feel like trade-offs, these fluids demonstrate that alignment is possible.

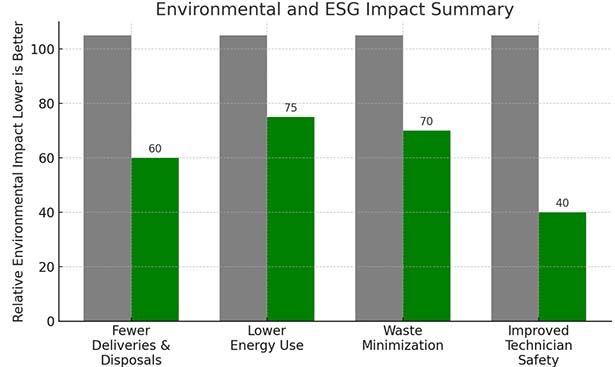

ESG Performance That Actually Performs

Sustainability is now embedded into corporate scorecards. Whether it’s via GRI, TCFD, CDP, or internal ESG metrics, leadership teams are looking for visible, quantifiable steps toward reduced environmental impact.

These fluids deliver on that front:

- Scope 1 reduction: Fewer oil deliveries, fewer disposals

- Scope 2 reduction: Lower energy use for heating, pumping, and handling

- Scope 3 reduction: Longer fluid life reduces supply chain and vendor activities

- Waste minimization: Less used oil, fewer filters, less packaging

- Improved technician safety: Fewer hot fluid changes, fewer slip/spill risks

Figure 3 – In addition to biodegradability, this fluid delivers other important sustainability benefits compared to conventional hydraulic oil.

For operations under regulatory pressure—e.g., near sensitive watersheds or operating under ISO 14001 guidelines—this can translate into real permitting and reporting advantages.

And because they are non-ester-based, these fluids have far greater in-field stability. They don’t compromise performance just to check a box.

Built for Harsh Conditions, Not Just the Lab

I’ve seen fluids perform well in lab tests only to break down in the field. That’s not the case here.

High-performance biodegradable fluids have been validated in extreme duty environments: open-pit mining, sawmills, marine cranes, and high-dust aggregate operations. Their resistance to oxidation, thermal breakdown, and moisture-induced degradation has been proven across thousands of hours in real systems.

That’s critical. Machines in these environments don’t operate in clean rooms. They’re exposed to:

- Large ambient temperature swings

- Contaminant ingress

- Long idle periods followed by full-load startup

- Operator variability

- Infrequent but high-risk maintenance access

These fluids are engineered to tolerate these realities. They stabilize system pressures, protect surfaces under mixed-film and boundary lubrication conditions, and resist the formation of varnish in servo valve lands.

Technician-Approved: Why the Front-Line Matters

Technicians are quick to call out underperforming fluids. And when fluid quality declines, they know the signs: pump noise, erratic cylinder movement, discoloration in sight glasses, filters clogging prematurely.

What’s been encouraging is the feedback from early adopters. These fluids don’t just survive in the field—they make the job easier.

Fewer changeouts mean fewer work orders to write, fewer tag-outs to manage, and fewer cleanups to oversee. It enables teams to focus on higher-value work and condition monitoring, not just keeping up with fluid top-ups and flushes.

Strategic Implications for Reliability Programs

Fluid choice is often seen as a procurement issue or a compliance issue. In reality, it’s a strategic enabler of maintenance effectiveness.

High-performance biodegradable fluids support:

- Fewer planned maintenance events

- Reduced reactive work due to component instability

- Longer filter life and pump mean time between failures (MTBF)

- More accurate condition monitoring (due to consistent fluid performance)

- Better alignment with PdM technologies like particle counting and water content sensors

In the context of a modern asset management system, they reinforce lean, predictable operations.

Sustainable Reliability, Delivered

I’ve trained thousands of people in lubrication best practices. And I’ve learned that reliability gains don’t always require more sensors, software, or capital outlay. Sometimes, they come down to smarter fluid decisions.

High-performance biodegradable hydraulic fluids represent that kind of decision.

They run longer, cleaner, and safer. They reduce environmental risk without sacrificing performance. And they give technicians and engineers the consistency they need to keep systems running to plan.

If you’re serious about hydraulic system uptime, technician safety, and sustainability metrics, don’t settle for a fluid that “meets the minimum.” Choose one that moves your entire operation forward.

With today’s advanced formulations, you get all the performance and none of the compromise.