Downtime is the silent thief of productivity. While many organizations chase improvements in Mean Time Between Failures (MTBF) to reduce how often assets fail, it’s equally important to address Mean Time to Repair (MTTR)—the average time it takes to restore a failed asset to operational status.

Focusing solely on MTBF can lead to diminishing returns if repair processes are inefficient. Every minute lost during recovery from a failure represents lost revenue, idle labor, and disrupted schedules. Improving MTTR ensures that when failures do occur—and they will—your organization is prepared to respond quickly and effectively.

MTTR includes all activities from the moment a failure is detected to the time the equipment is handed back to operations. Reducing MTTR not only boosts uptime but also contributes to improved Overall Equipment Effectiveness (OEE), better customer delivery performance, and lower maintenance costs.

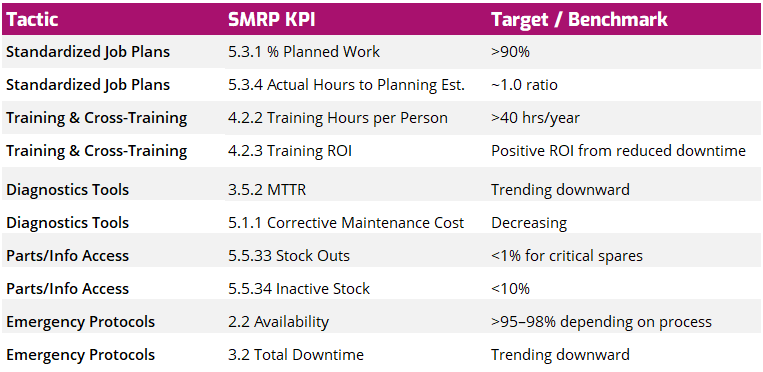

This article outlines five essential tactics to systematically reduce MTTR across your operation. Each is paired with relevant KPIs from the SMRP Best Practices Guide to provide actionable benchmarks.

Tactic 1: Standardize and Strengthen Job Plans

Why It Matters

When a breakdown occurs, the last thing a technician should do is improvise. A well-written job plan provides step-by-step guidance, the right parts, proper tools, and safety instructions—all prepared in advance.

What to Do

- Create reusable job plans for critical assets and common failure modes.

- Include task durations, photos or diagrams, torque specs, LOTO steps, and necessary permits.

- Pre-kit parts and tools for fast retrieval.

- Store all plans in a centralized CMMS or digital library accessible in the field.

Relevant SMRP KPIs

- 3.1 Planned Work (%) – Target: > 90%

- 3.4 Actual Hours to Planning Estimate – Target: Ratio close to 1.0

Tactic 2: Invest in Hands-On Training and Cross-Training

Why It Matters

A highly skilled, confident technician team can diagnose and repair faster, especially under pressure. Cross-training expands flexibility during staff shortages or when specialist help isn’t immediately available.

What to Do

- Focus training on troubleshooting, OEM repair practices, and condition monitoring basics.

- Pair junior staff with experienced mentors.

- Use simulations or tabletop scenarios based on historical failures.

Relevant SMRP KPIs

- 2.2 Maintenance Training Hours per Person – Target: >40 hrs/year per technician

- 2.3 Maintenance Training ROI – Track: % reduction in reactive labor hours and rework

Tactic 3: Use Diagnostic Aids and Condition Monitoring Data

Why It Matters

Most repair time is lost in diagnosis, not the repair itself. Equipping technicians with structured fault-finding tools speeds the identification of root causes and eliminates guesswork.

What to Do

- Deploy fault trees, checklists, and quick-reference guides for critical systems.

- Use ultrasound, infrared, and vibration data to pre-identify issues.

- Create a failure mode database tied to CMMS records.

Relevant SMRP KPIs

- 5.2 Mean Time to Repair (MTTR) – Track: Asset-level trend over time

- 1.1 Corrective Maintenance Cost – Track: Decrease due to faster and more accurate repairs

Tactic 4: Ensure Immediate Access to Technical Info and Parts

Why It Matters

Delays in retrieving manuals, prints, or replacement parts are a major MTTR bottleneck. Fast access means faster action.

What to Do

- Provide field technicians with tablets or mobile access to equipment manuals, schematics, and past work orders.

- Audit and optimize storeroom layout and stock levels.

- Use barcoding or RFID to locate critical spares instantly.

Relevant SMRP KPIs

- 5.33 Stock Outs (%) – Target: <1% for critical spares

- 5.34 Inactive Stock (%) – Target: <10%

- 3.5 Planning Variance Index – Track: Reduction in unplanned delays due to missing parts

Tactic 5: Formalize Emergency Response Protocols

Why It Matters

When a high-impact asset fails, confusion or slow escalation can prolong downtime. Structured response plans bring order to chaos.

What to Do

- Define emergency repair protocols by asset criticality.

- Assign clear roles for notification, diagnostics, and response.

- Keep a playbook for top critical assets with troubleshooting steps and contact info.

- Conduct drills for ‘Red Alert’ failure scenarios.

Relevant SMRP KPIs

- 2 Availability (%) – Target: >95% for batch; >98% for continuous processes

- 2 Total Downtime (Hours) – Track: Reduction over time

Case in Point: Die Cleaning Time Slashed by 66%

When I was the maintenance manager at a 24/7 plastic film manufacturing facility, one of our chronic bottlenecks was the extrusion die cleaning process. Originally, it took 72 hours to clean a flat film die, primarily because it had to be disassembled and transported to the maintenance shop. Skilled maintenance personnel handled the entire procedure, and occasional assembly errors even caused additional downtime due to warped dies.

We decided to overhaul the process. First, we created a standard job plan that included lockout instructions, staging areas, special tool requirements, and clearly defined steps. We also relocated the cleaning worksite next to the line, implemented mobile tool stations, and used precision torque wrenches to prevent reassembly damage. Importantly, we trained operations personnel to take over the cleaning steps, freeing up maintenance resources.

By the first trial, we had already reduced cleaning time to 24 hours—a 66% improvement. More importantly, we avoided the reoccurrence of warped die assemblies and captured an additional 48 hours of uptime each cleaning cycle.

The key lesson? Reducing MTTR isn’t just about speeding up repairs—it’s about preparing relentlessly, sharing ownership, and fostering collaboration between maintenance and operations.

Sample KPI Table for MTTR Improvement