One of the major areas of focus in industry today is improving equipment reliability. Why? To ensure that production is always available to meet the demand of the marketplace. One of the worst nightmares of any company and those who manage it is to have a demand for product but not be able to supply it because of equipment failure.

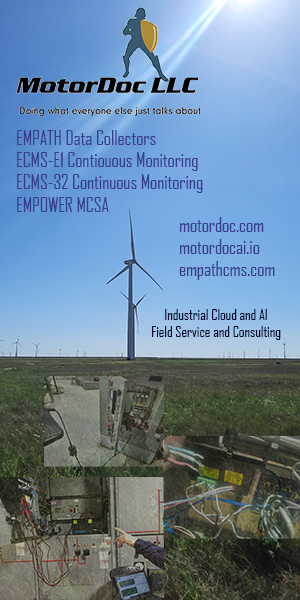

Certainly, this scenario will reduce company profitability and could ultimately put a company out of business. There is a large difference in cost between a reactive and a proactive maintenance organization. See the chart below and think about whether change is necessary in your organization.

Maintenance Costs in Typical and World-Class Companies

The High Cost of Unreliable Operations

For some firms, poor reliability and its impact on production are far more serious than for others. For those that operate on a continuous basis—they run 24 hours per day, seven days per week—there is no room for unplanned shutdowns of the production equipment; any loss of production is often difficult or even impossible to make up.

When production can’t stop, failure finds its cost in seconds, not days.

For others that do not operate in a 24/7 mode, recovery can be easier, but nevertheless, time-consuming and expensive, reducing profits.

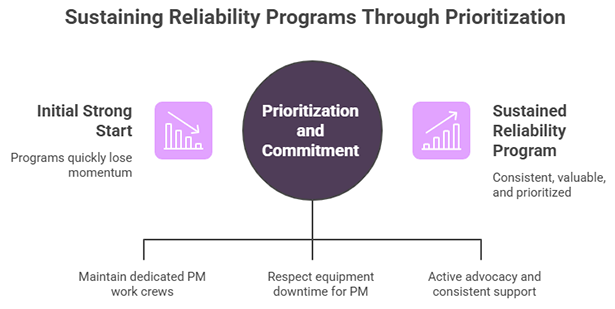

Why Most Reliability Programs Start Strong and Fail Fast

Many programs available in the industry are designed to help businesses improve reliability. They are identified in trade literature, promoted at conferences and over the web, and quite often they are in place within the plants in your own company.

The loudest cheerleaders at launch often become the quietest saboteurs.

Most of these programs are “hard skill” programs. They deal with the application of resources and resource skills in the performance of a specific task aimed at reliability improvement.

For Example, to improve “Preventive Maintenance”:

- Train your workforce in preventive maintenance best practices, and perform a PM Optimization focused on a specific production line or area.

- Roll out your optimized PM program accompanied by corporate publicity, presentations of what you expect to accomplish, and other forms of hype to get buy-in from those who need to execute it, post a PM Scorecard, and define Roles and Responsibilities.

- Then you congratulate your team for a job well done and move on to the next project. Often at this juncture, something very significant happens.

- The program you delivered starts strongly, but immediately things begin to go wrong. The work crews assigned to preventive maintenance get diverted to other plant priorities; although promises are made to return them to their original PM assignments, this never seems to happen.

- Equipment scheduled to be out of service for preventive maintenance can’t be shut down due to the requirements of the production department; although promises are made to take the equipment off-line later, this never seems to happen.

- Finally, the various key members of management who were active advocates and supporters at the outset are the very ones who permit the program interruptions, diminish its intent, and reduce the potential value. Often, these people attempt to get the program back on track, but these attempts are half-hearted.

Although nothing is openly said, the organization recognizes what is important, and often this is not the preventive maintenance program. (Steve Thomas simplifies the demise of the preventive maintenance program in an example.)

Cultural Signals That Undermine Reliability Efforts

Yet this is exactly as it happens, although much more subtle.

In the end, the result is the same. Six months after the triumphant rollout of the program, it is gone. The operational status quo has returned and, if you look at the business process, you may not even be able to ascertain that a preventive maintenance program ever existed at all.

For those of us trying to improve reliability or implement any type of change in our business, the question we need to ask ourselves is “Why does this happen?” The intent of the program was sound. It was developed with a great deal of detail, time, and often money: the work plan was well executed. Yet in the end, there is nothing to show for all of the work and effort.

Part of the answer is that change is a difficult process. [Note that we did not say program, because a program is something with a beginning and an end.] A process has a starting point—when you initially conceived the idea—but it has no specific ending and can go on forever.

Yet the difficulty of implementing change isn’t the root cause of the problem. You can force change. If you monitor and take proper corrective action, you may even be able, over the short term, to force the process to appear successful. Here, the operative word is you.

Why Sustained Change Requires More Than Oversight

What if you implement the previously mentioned preventive maintenance program and then, to assure compliance, continually monitor the progress? Further, suppose that you are a senior manager and could rapidly remove from the process change any roadblocks it encounters as it progresses.

Programs die when care and feeding stop—sustainability is a leadership choice.

What then? Most likely, the change will stick if you provide care and feed. But what do you think will happen if you are removed from the equation after one month into the program? The program will most likely lose if there are no other supporters to continue the oversight and corrective action efforts.

Step 1

Educate the plant management on the basics of reliability, which involves how equipment fails, how to monitor equipment health, and how to make the right decision at the right time so as not to see equipment failure.

Step 2

Assess the current state of your Maintenance Process

Step 3

Assemble all the information for the business case.

This information could be sketchy, depending on how reactive an organization is.

The information must include:

- Asset reliability data (plant, production line, critical assets’ mean time between failure). This information should be available from CMMS/EAM if work orders have been written for most failures.

- Maintenance labor costs: overtime percentage-plus cost (do not include “full burden” cost), yearly labor cost for current-year budget, yearly labor cost for past three to five years, contractor cost used to assist in maintenance projects or maintenance work, and any other labor cost that may be important.

- Maintenance material costs (specify a dollar amount):

- Maintenance storeroom inventory level

- Maintenance material expenditures for the past three to five years

- Overnight delivery costs for the past three to five years

- Additional costs associated with maintenance parts storage and procurement.

- Current plant capacity and capacity targets and goals for the current year and past three to five years.

- Marketing forecast for next one to three years (if available) in total sales.

- Quality losses for the current year and the past three to five years.

Note: Other costs could be useful in developing the business case, just be sure that any cost the business case claims will be financially affected by the reliability initiative and can be validated by the financial person.

Step 4

Develop the business plan with plant management. Expect this exercise to take one to two days, depending on the availability of the information. If any required members cannot participate fully, then do not proceed with this process. Required team members are the plant manager (do not move ahead without him or her), production manager, chief financial officer, comptroller, or plant accountant, maintenance and engineering manager, safety director (or person responsible), and environmental director (or person responsible).

Step 5

Calculating savings. Once all the data is compiled, begin identifying past losses and potential savings for each of the following areas, based on the current reliability of the assets against the future state. For example:

- Current capacity: 88% (the number has generally been the same over the past three years).

- Sales projections: Could sell all products produced—1% increase in capacity increases the bottom line by $150,000 a day; plant operates 365 days a year = $150,000 × 365 days = $54.75 million.

- Potential savings: What is the impact of reliability on production? In most plants, reliability increases capacity by as much as 98%; say 50% to be conservative.

- New calculations for savings = 50% × $54.75 million = $27.375 million.

- Time until this savings affects the bottom line (educated guess): Aggressive reliability initiative = (“under commit, overdeliver”)

- Year 1 = 10% improvement = $2,737,500.

- Year 2 = 20% (plus last year’s 10%) = $8,212,500.

- Year 3 = 30% (plus last two year’s 30%) =$16,425,000.

- The savings or just the increase in capacity equals $16,425,000 in three years. Recalculate the savings after adding savings from a reduction in maintenance costs, including maintenance labor and materials. It should equal or exceed the plan’s cost in a short time.

- In addition to the profit from increased capacity, also identify the following:

- Decrease in maintenance labor cost over three years = 30% = $4 million.

- Decrease in maintenance material cost over three years = 20% = $1.2 million

Step 6

Develop an action plan with a timeline that identifies the major task defined; defined roles and responsibilities by position, from the floor level to boardroom for each task; defined key performance indicators to measure success of the project (establish targets and goals); established measures of success for specific positions, which align responsibilities; and defined milestones with cost and savings identified. and defined milestones with cost and savings identified.

Step 7

Present the business plan to senior management. Spend time doing it right, and make it professional and appealing. Rehearse the presentation. Remember, you only have one chance at this sales presentation.

- Use a PowerPoint presentation (no more than 10 slides) to show the benefits (it is all about the money), costs (play up the return on investment), and project plan abbreviated (give an overview); then present a large chart with the project plan attached make it shine, make a statement with it.

Once this project has been approved, have consultants ready to assist in training and coaching the staff to make this reliability project effective. A consultant will have experienced many failures and many successes. Do not try to reinvent the wheel.