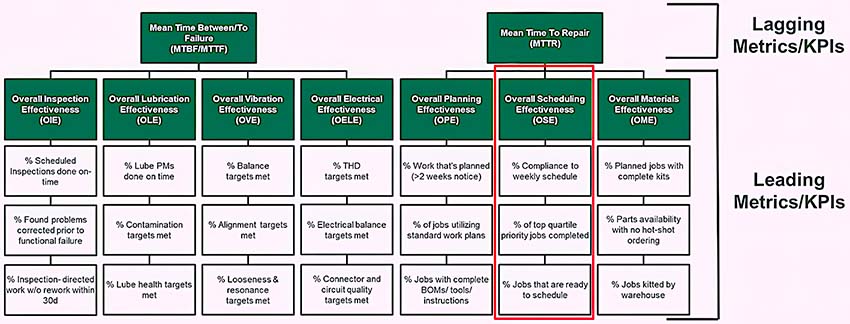

Overall Scheduling Effectiveness (OSE) is a leading indicator that drives proactive behaviors, which, in turn, drives asset reliability.

What OSE Is and Why It’s Important

Ultimately, the planning, scheduling, and maintenance-work-management process aims to complete as much high-quality, top-priority work as possible. In most plants, non-Shutdown, Turnaround, or Outage (STO) maintenance work that will be scheduled for the following week is agreed to in a scheduling meeting (typically on Wednesday or Thursday of the current week to allow a day or two for adjustments).

The schedule is agreed upon as a byproduct of a job priority-based joint challenge that typically includes maintenance and operations leadership. The Overall Scheduling Effectiveness (OSE) metric is intended to drive proactive maintenance- work-scheduling behaviors to help ensure this goal is met.

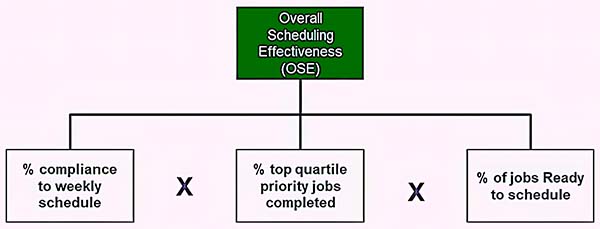

OSE is calculated as the product of multiplying the following three input factors:

- Percentage of jobs assigned to the weekly schedule that were actually completed, i.e., compliance to schedule.

- Percentage of top-quartile priority jobs that were completed.

- Percentage of jobs that are ready to schedule.

The simple formula for OSE is the product of multiplying the ‘behavioral inventories’ for the three input factors.

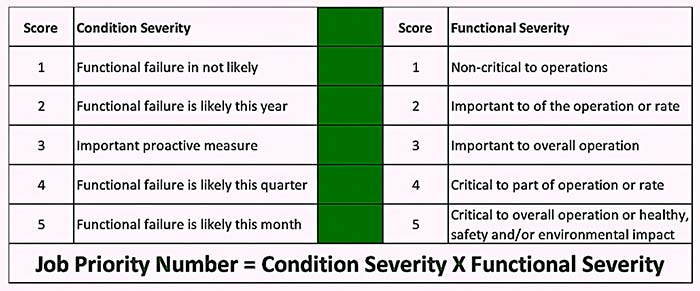

Integral to the OSE metric is the relative importance of each candidate job. I suggest creating a process for assigning a Job Priority Number (JPN) to each job being considered for inclusion in the next week’s schedule. A simple example of such a prioritization system is illustrated in the figure below.

In it, an assigned Condition Severity Score (CSS) of 1 to 5 is multiplied by a Functional Severity Score (FSS) of 1 to 5 that’s assigned to all jobs. This results in a JPN range of 1 to 25 (1 is the lowest priority, and 25 is the highest priority).

As your asset-management effectiveness improves, the average JPN for all demanded maintenance jobs should be reduced. This is a clear indicator that you’re becoming more proactive in managing the reliability of your equipment assets.

A simple example of a pseudo-quantitative scoring system for assigning priority to jobs that are available to schedule.

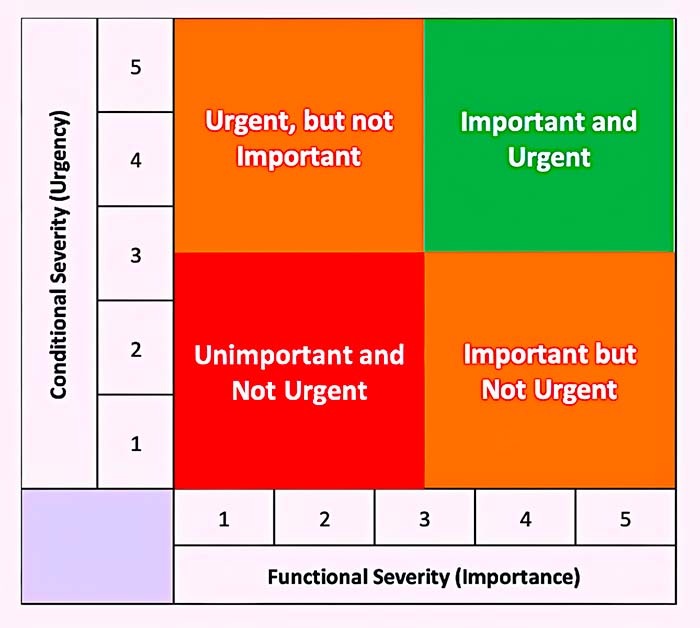

Assigning a JPN to each job lets us organize the demanded jobs according to the four-box urgency vs. importance matrix from Stephen Covey’s book, The 7 Habits of Highly Effective People. The Covey “Urgency vs. Importance Matrix” can be adapted to the maintenance JPN scoring and ranking system to visually reflect the most important work.

Stephen Covey’s famous “Urgency vs. Importance Matrix” adapted to the maintenance Job Priority Numbering (JPN) System.

As with other leading metrics, we must view the OSE elements as an inventory process of binary observations: The job complies or doesn’t. Each element of the OSE metric is displayed as a percentage of the complying observations divided by the total number of observations and converted to a percentage.

The OSE is the product of multiplying the three components together. If OSE increases, we’re practicing behaviors that will drive MTTR down, which is our goal. Let’s explore the three components of OSE in more detail.

1. Percent Compliance to the Weekly Schedule

Success in the scheduling process depends upon compliance to the weekly schedule. Deviations occur as break-down or break-in work identified within the current schedule week.

Break-down work occurs due to a functional failure that affects all or part of production and/or introduces an unacceptable safety and/or environmental risk. Break-in work occurs when a high-risk condition observed inside the current schedule week is deemed high enough to break into the schedule and bump a job that was originally scheduled.

A break-down job often leaves us with little choice: We may need to bump a scheduled job to get the plant up and running or clear a safety or environmental issue. Break-in work is trickier, requiring real-time reshuffling of work priorities (sometimes without complete JPN details about the demanded break-in job).

We often reflect on a week’s work and conclude that we bumped an important scheduled job to deal with a break-in job that, in retrospect, would have carried a lower JPN had our analysis been more complete. Therefore, carefully considering a job’s importance and urgency is crucial.

Compliance to the weekly schedule is simply the number of jobs that were completed and scheduled divided by the total number of jobs that were scheduled, expressed as a percentage.

So, if 20 jobs were scheduled and 16 of them were completed, the percentage compliance to the weekly schedule is 80%, based upon the raw, binary “Yes vs No” job completion status. It is possible to additionally track a weighted value to reflect the different values associated with completing a 10-crew-hour job as compared to a 2-crew-hour job.

Carefully considering a job’s importance and urgency is crucial for scheduling success.

I usually encourage my clients to schedule 120% or 125% of their available crew hours. Thus, if I have 160 crew hours of available labor for next week, I will schedule 200 (125% of the available crew hours). The reason for this is simple: The goal for scheduling is to complete as much of the highest-priority work possible, given the available crew hours.

Sometimes, a scheduled job is bumped due to an unanticipated unavailability of parts, tools, contract labor, etc. So, it’s always good for the foreman or supervisor to have some wrench/spanner-ready go-to jobs in their back pocket. Of course, these “extra jobs” can’t require much prework, special-tool hire, or contract labor to complete.

Interestingly, I often get pushback on this approach. When I ask why, it comes down to optics. If I have the manpower for 20 jobs next week and I bump the number to 125% (or 25 jobs), and we complete the same 16 jobs, our compliance percentage drops from the previous 80% to 64%.

Yes, this would look bad. However, by multiplying 64% by the 125%, we arrive back to an 80% compliance. (Isn’t math beautiful?) The math for calculating the adjusted compliance percentage is a little more complicated, but it’s still simple arithmetic. (I’ll address this topic in that previously mentioned future article.)

2. Percentage of Top Priority Jobs Completed

The schedule compliance components of the OSE address the total amount of work completed. The Percentage of Top Priority Jobs Completed component assures that we focus on the most important work. Unlike other elements in this series of leading metrics that are essentially an inventory of binary “Yes vs. No” inputs, this value requires that we sum the total JPN values for all jobs on the schedule.

Then, we sum the JPN score for all scheduled jobs that we completed (Yes or No [binary in that sense]) and divide the sum value of their JPNs by the sum value of the JPNs for all scheduled jobs and express it as a percentage.

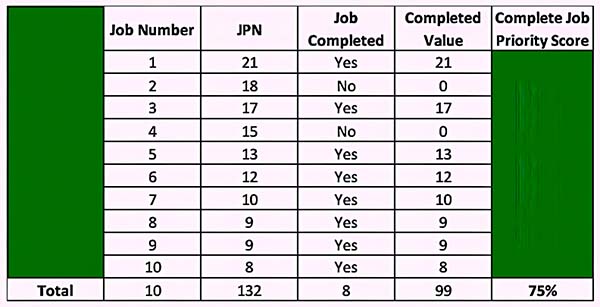

The figure below shows that the sum of the JPN values for the 10 scheduled jobs is 132 JPN points. Eight of those jobs were completed, thus reflecting a total of 99 of the 132 JPN points scheduled or 75% of the total JPN points scheduled for the week.

If OSE increases, we’re practicing behaviors that will drive MTTR down.

Example of the process from calculating the Percentage of Top Priority Jobs Completed component of the OSE metric.

3. Percentage of Scheduled Jobs That Are Ready to Schedule (RTS)

Chasing down parts is a big crew-utilization killer. Failure to erect scaffolding, awaiting permits and access to the equipment, waiting for special tools, and other issues adversely affect crew productivity and, in some instances, work quality. So-called wrench/spanner time depends upon our crews having the necessary parts and tools to complete the job.

Materials management ties the planning, scheduling, and warehouse-management functions together. You can bet that if our crews spend most of their time seeking parts, our job-completion compliance will suffer, and our performance in completing top-priority jobs will likely suffer.

Note: It is the scheduler’s job to ensure that a job is Ready to Schedule (RTS). To do that, the scheduler must coordinate with the planner, the materials warehouse, operations, and other stakeholders to ensure the following boxes (shown in the graphic below) are ticked and confirm that the job is a go:

- All required parts and materials identified in the bill of material (BOM) must be verified to be on-hand.

- Any special tools required to complete the job, including any outside tools hired, are available.

- Any scaffolding or other required prework has been completed or will be completed before the commencement of job completion.

- Access to the equipment has been approved, permitted, and coordinated with operations as required.

- Job plans and work instructions are complete and wrench/spanner-ready, including the following:

- Preliminary Job/Safety/Hazards Analysis (JSA/JHA)

- Complete bill of materials (BOM)

- Tools required to complete the job

- Precision work instructions, including fit, tolerance, quantity, and quality details

- Required work-quality inspections or checks

Minimizing Mean Time To Repair (MTTR) is essential for increasing production availability in the plant. Doing so requires effective scheduling of maintenance work.

The scheduler must first ensure that a job is in a Ready to Schedule (RTS) status from a planning and materials perspective. Then, they must coordinate a joint challenge between maintenance, operations, and other stakeholders to assign or adjust each job’s Job Priority Number (JPN).

Monitoring Overall Scheduling Effectiveness components drives behaviors that boost work quality and crew performance.

I advise that we schedule 120% to 125% of available crew hours to ensure that we have enough wrench/spanner-ready work to address scenarios where a higher-priority job is bumped for one reason or another.

By monitoring the three elements of Overall Schedule Effectiveness (OSE), you can drive proactive behaviors in the plant that will decrease your MTTR, improve work quality, and boost crew utilization or wrench/spanner-time performance.