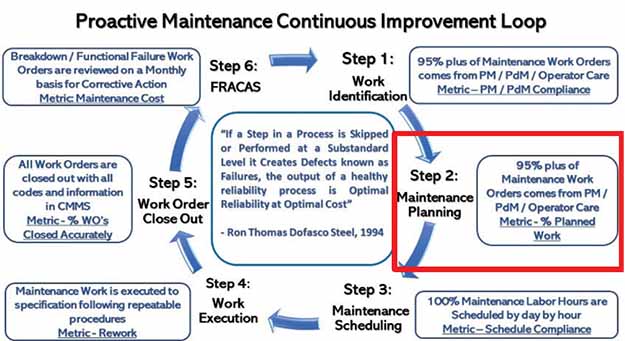

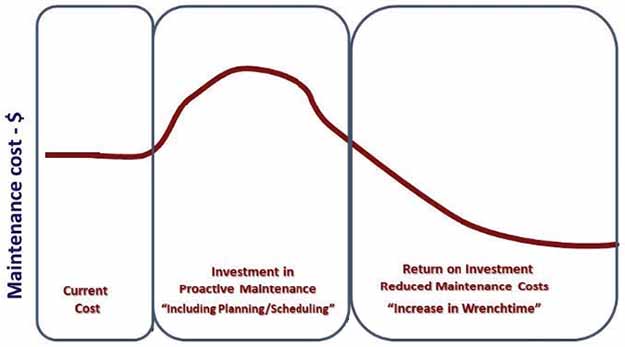

Maintenance Planning and Scheduling is critical to the success of any maintenance organization. This results in a significant increase in wrench time (hand-on tool time). Planning and Scheduling are two distinct functions that are dependent on each other.

Maintenance Planning

Maintenance Planning is a highly skilled function that requires a basic knowledge of maintenance work processes, operations expectations, project management, computerized maintenance management system (CMMS), and related systems and a practical understanding of the work to be performed.

Planning is the “what’s required” and “how to” part of any maintenance job.

Maintenance Planning Typical Requirements

- Parts/Materials

- Specifications

- Instructions (Repeatable)

- Coordination requirements

- Estimated time

- Repeatable procedure

- Safety/Environmental Requirements

Maintenance Scheduling

Maintenance Scheduling is the process by which all proactive maintenance activities are scheduled by day and hour in coordination with Production at least one week in advance.

Maintenance Scheduling Typical Requirements

- A Maintenance Scheduling Meeting, managed by the Maintenance Planner/Scheduler.

- Production and Maintenance leadership agreement on the schedule by day and hour one week prior to scheduled work execution.

- All parties must agree upon the Maintenance Schedule before scheduling the meeting.

- A Maintenance Scheduling Meeting, typically held every Thursday for 30 minutes, led by the Maintenance Planner/Scheduler to ensure nothing has changed for the next week’s schedule.

- Personnel attending the Scheduling meeting:

- Maintenance Planner/Scheduler

- Maintenance Supervisor

- Production Supervisor/Manager

- Plant/Reliability Engineer (optional – dependent on potential interference with next week’s schedule due to contractor, project interference with schedule).

- Measurements (prefer a dashboard posted in the plant):

- Breaks to the schedule by type of break, e.g., Production could not release equipment on time, no parts were available, maintenance labor was unavailable, etc.

- Schedule Compliance

- PM Compliance

- OEE

Maintenance Planning and Scheduling Scorecard

Planning and Scheduling is an Investment, Not an Expense

Planning and Scheduling Vision, Mission, and Guiding Principles

Planning and Scheduling Vision Statement

To plan and schedule maintenance work in order to optimize asset and process reliability at optimal cost.

“doing the right work at the right time.”

Planning and Scheduling Mission Statement

Maintenance Planning and Scheduling is to enable proactive maintenance through increased “wrench time,” enabling optimal production process reliability at optimal cost.

Planning and Scheduling Guiding Principles

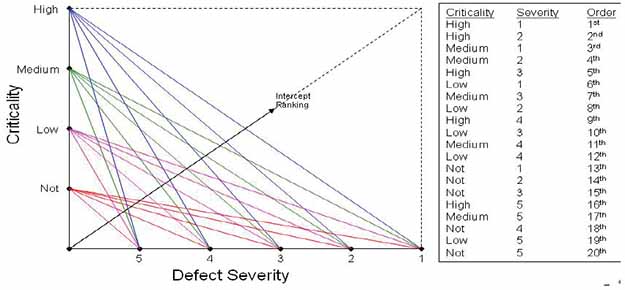

- Scheduling uses a combination of Defect Severity and Asset Criticality to determine scheduling work orders.

- Maintenance Planners focus on future work only; today’s issues are handled by Maintenance Supervisor or Lead Person

- Maintenance Planners plan and schedule “MAINTENANCE WORK”

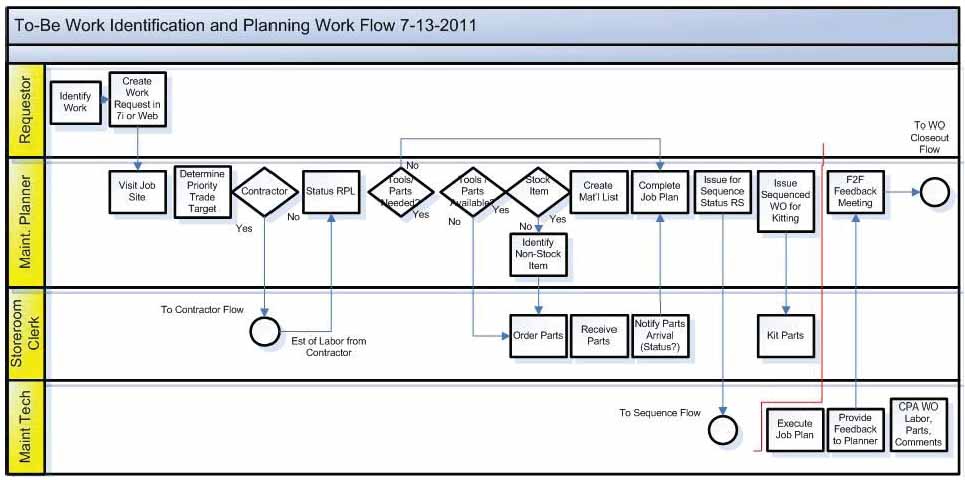

- All work “Scheduled” which requires parts/materials are kitted in a secure area

- All Planned and Scheduled work is tracked through status codes, see “Status Codes” below:

- RTS – Ready to Schedule (parts kitted and staged/secure)

- AP – Awaiting Parts

- A WP- Awaiting Production

- All Work Scheduled is scheduled by day and by hour

- Scheduling meetings are held on Thursday for FINAL review of the following week’s maintenance schedule with Production, Maintenance, and others as required (i.e. Contractors, Safety)

- Maintenance Planners facilitate the meeting, and typically last 30 minutes

-

- Required attendees, Maintenance Planner, Maintenance Supervisor, Production Supervisor, Contractor (optional), Maintenance/ Reliability Engineer

- Leading and Lagging KPls are used to manage the Planning, Scheduling, and Work Execution Process.

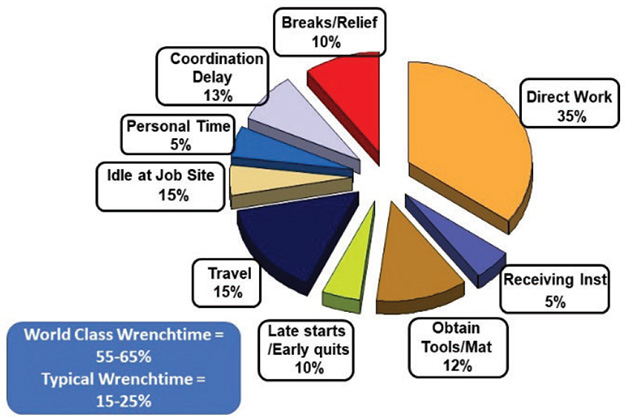

Wrench-Time

Wrench time is a measure of maintenance personnel’s time accomplishing proactive work on time, on schedule, and on budget.

Wrench time does not include time obtaining parts, tools, instructions, work associated with those tasks, traveling to or from job sites, or time spent obtaining work assignments. It is about only focusing on “hands-on tool” time.

Wrench Time “Hands-On Tool Time”

- Wrench time is a measure of crafts personnel at work, using tools, in front of jobs.

- Wrench time does not include obtaining parts, tools, instructions, or the travel associated with those tasks.

- It does not include traveling to or from jobs.

- It does not include time spent obtaining work assignments.

Steps to Success in Maintenance Planning and Scheduling

Step 1: Identify External Distracters

- Poor spare parts and inventory controls

- Conflicting ideas of what planning is

- No planner (if you have no planner, assign your best maintenance technician to become your planner and send them to formal training) Write a Work Order scheduling the technician to this position until the company creates a new position)

- Planners taken off job, put on tools, or involved in daily activities (parts chaser, facilitating daily work)

- Maintenance and Production not acting as a team

- No planning process, unclear expectations, unclear roles and responsibilities

- Maintenance leadership not following the plan

- Emergency / urgent work too high

- Lack of discipline

- The CULTURE

Step 2: Education of the Team – “Coaching is not just for Planners Anymore”

- Plant / Operations Leadership

- Frontline Production Leadership

- Maintenance and Reliability Leadership (all levels)

- Planners

- Maintenance

- Personnel

- Operators

“If you send a Maintenance Planner to Training, be sure you send your best technician or maintenance supervisor as well; change is never easy.”

Step 3: Create Guiding Principles for Planning and Scheduling

- The planners focus on future work and maintain at least two weeks of work backlog that is planned, approved, and ready to schedule/execute.

- Planners Do Not Chase Parts for Jobs in Progress

- Supervisors and Crew Leads Handle the Current Day’s Work and Problems – Coordination

- Scheduling Does Not Occur Until Parts are Kitted

- We will maintain a stable/nonfluid Criticality Index

Step 4: Define the Planning and Scheduling Processes

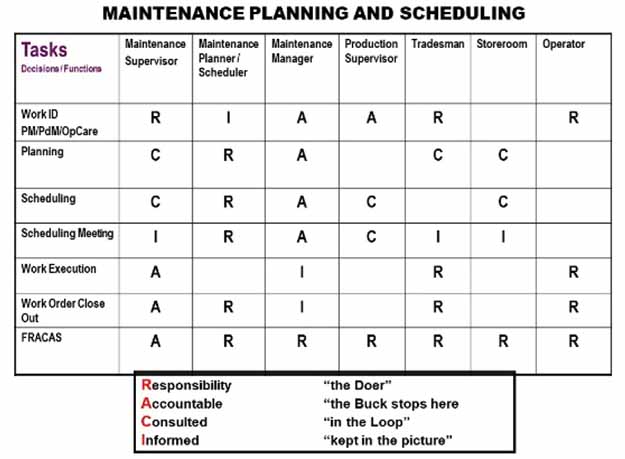

Step 5: Define Roles and Responsibilities

Step 6: Prioritize Work to be Planned based on Asset Criticality and Defect Severity

Step 7: Develop Repeatable Procedures for all Maintenance Work to:

- Ensure repeatability and reduce variation in execution

- Capture Knowledge based on past issues/failures

- Train New Employees with Repeatable Procedures

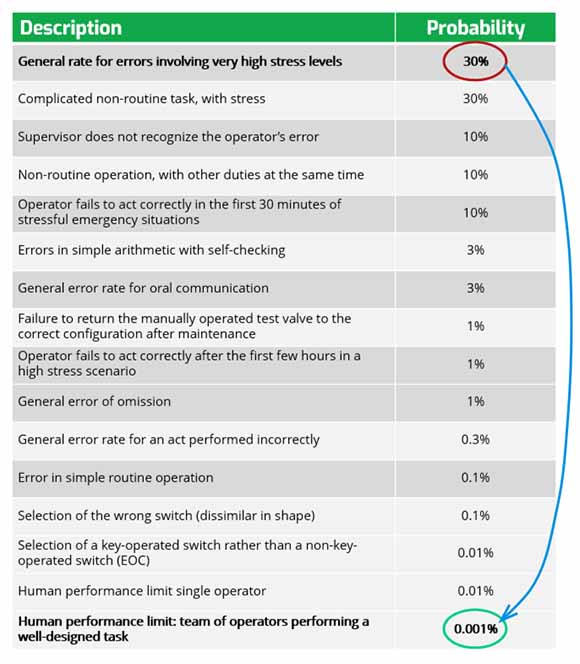

- To Reduce Human Error

Human error refers to something having been done that was “not intended by the actor; not desired by a set of rules or an external observer; or that led the task or system outside its acceptable limits”.

Step 8: Create a Maintenance Planning and Scheduling Dashboard

This is for all to see every day. People are motivated by knowing their score in any process, which is critical to an organization.

Maintenance Planning and Scheduling Scorecard

How to Create a Maintenance Planning and Scheduling Dashboard

- Assemble a cross-functional team, Maintenance Planner, Maintenance Supervisor, Production Supervisor, Storeroom Manager

- Determine the steps in the Maintenance Planning and Scheduling Process

- Create a metric for each step in this process

- Agree on the goal of each metric and how it will be measured effectively

- Determine Roles and Responsibilities if specific metrics are meeting expectations

- Use Root Cause Analysis (5 Whys) to identify why specific metrics are meeting expectations if this occurs

Ricky Smith, CMRP, CMRT is the Vice President of World Class Maintenance and a leading Maintenance Reliability Consultant with over 35 years of experience. He holds certifications such as Certified Maintenance and Reliability Professional (CMRP) and Certified Maintenance and Reliability Technician (CMRT). Ricky has worked with global companies like Coca-Cola, Honda, and Georgia Pacific, delivering expert maintenance solutions across 30 countries. His career began in the U.S. Army, advancing to leadership roles, including a position at the Pentagon as Facility Investigator for the Secretary of Defense. Ricky is also the co-author of Rules of Thumb for Maintenance and Reliability Engineers and Lean Maintenance: Reduce Costs, Improve Quality, and Increase Market Share.