This article targets the ‘first responders’ who arrive immediately at the failure scene. These people must ensure the area is safe, preserve the scene for investigators, and contribute to a plan to expedite a quick, safe return to production norms.

Many must understand how valuable failed parts are to metallurgical/forensic investigators. Broken parts are to metallurgists like a murder weapon is to a forensic crime investigator.

This article aims to educate those who have first access to the failed parts and why they should preserve them in their failed state (not clean them up). We want to give them enough knowledge to be dangerous and raise their curiosity about making a call about the fracture patterns they see.

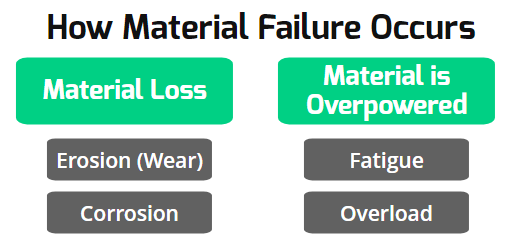

Most components fail for one or a combination of four (4) primary physical reasons.

- Erosion

- Corrosion

- Fatigue

- Overload

When investigating failures involving components, their fractured surfaces tell a story about what happened to them. As you approach any such failure scene, try to visualize being that failed part and think, “What just happened to me?”

Visualize the part being in operation and the forces affecting it. It seems corny, but it is a very effective approach to understanding what happened. Let’s explore the basics of these very involved failure patterns.

Erosion

Erosion is caused by particles in the process medium contacting and damaging a surface. Erosion can be delivered from fluid/air:

- Fluid/air contaminated (particles present)

- Fluid/air viscosity changed

- Fluid/air velocity changed

- Material eroding is wrong material for existing service

- Materials are not compatible

Erosion can be abrasive or adhesive. Here are some basic examples:

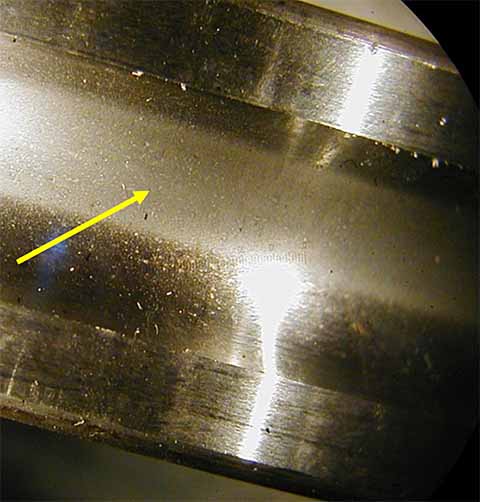

Abrasive Erosion – Bearing

Abrasive Erosion – Bearing Inner Ring Erosion from Contaminated Lubrication

Adhesive Wear – Bearing

Adhesive Wear – Bearing

Corrosion

Corrosion is the deterioration of a material due to interaction with its environment. It is the process in which metallic atoms leave the metal or form compounds in the presence of water and gases.

Metal atoms are removed from a structural element until it fails, or oxides build up inside a pipe until it is plugged. Corrosion is an electrochemical process. It can be complicated. Identifying that there is corrosion should be sufficient for novices. Further detailed analysis should be performed by a qualified professional.

There are several types of corrosion, such as:

- Uniform Attack

- Pitting Corrosion Attack

- Crevice Corrosion Attack

- Galvanic Corrosion Attack

- Erosion-Corrosion Attack

- Stress Corrosion Cracking

- Fretting Corrosion Attack

Numerous variables can create corrosion. Here are some:

- Contamination/impurities

- Water quality

- Aeration

- Galvanic couples

- Material selection

- Effects of welding

- Stagnation

- Turbulence

- Pressure

- Deposits

- Crevices

- Startups and shutdowns

Here are some basic examples of each type of corrosion:

Pitting Corrosion Attack

Pitting corrosion is highly localized corrosion occurring on a metal surface. Pitting is commonly observed on surfaces with little or no general corrosion. Pitting typically occurs as a process of local anodic dissolution where metal loss is exacerbated by the presence of a small anode and a large cathode.

Uniform Corrosion Attack

Uniform corrosion can be described as a corrosion reaction that takes place uniformly over the surface of the material, thereby causing a general thinning of the component and an eventual failure of the material.

Galvanic Corrosion Attack

Accelerated corrosion which can occur when dissimilar metals are in electrical contact in the presence of an electrolyte. Galvanic attack can be uniform or localized at the junction between the alloys depending on service conditions. Galvanic corrosion can be severe under conditions where protective corrosion films do not form, or where they are removed by conditions of erosion-corrosion.

Erosion-Corrosion Attack

Erosion Corrosion is where the rate of attack by a corrosive agent is accelerated by the velocity of the corrosive moving across the metal surface.

Stress Corrosion Cracking (SCC)

SCC is the brittle cracking of a metal due to the result of combined effects from localized corrosion and tensile stress. There are many examples in which specific metals and environments in combination cause such problems.

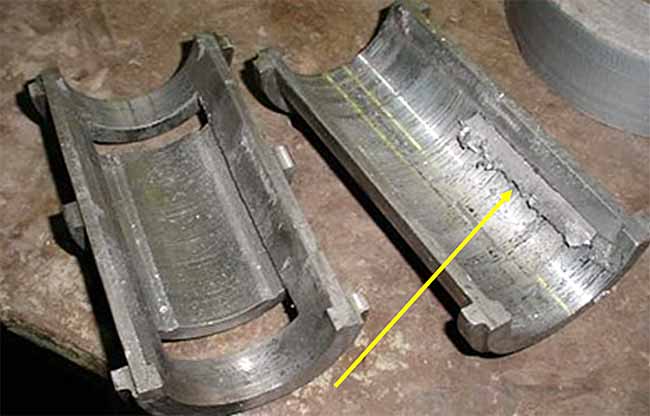

Fretting Corrosion Attack (Poor Housing and/or Shaft Fit)

Fretting corrosion is corrosion that can occur on the load bearing contact surface between mating material. It is caused by the combination of corrosion and the abrasive effects of corrosion product debris often seen in equipment with moving or vibrating parts.

Crevice Corrosion Attack

Crevice corrosion is localized corrosion that may occur in small areas of stagnant solution in crevices, joints, and under corrosion deposits.

Fatigue

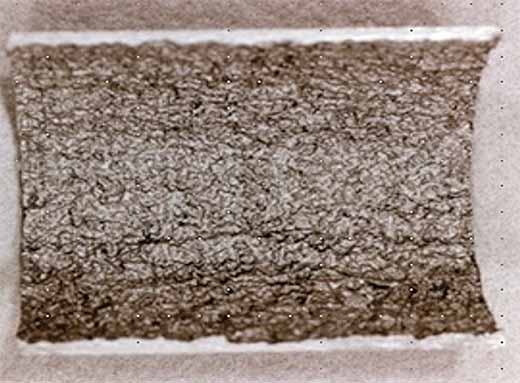

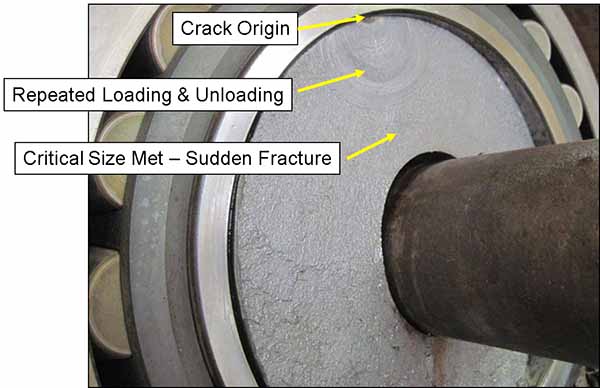

Fatigue is the most common fracture pattern, occurring in about 90% of the cases.

- Fatigue occurs when a material is subjected to repeated loading and unloading.

- When the loads exceed a certain threshold, microscopic cracks will form at a material’s surface.

- Cracks always begin in highly stressed areas of a material.

- Eventually, a crack will reach a critical size, and the structure will suddenly fracture.

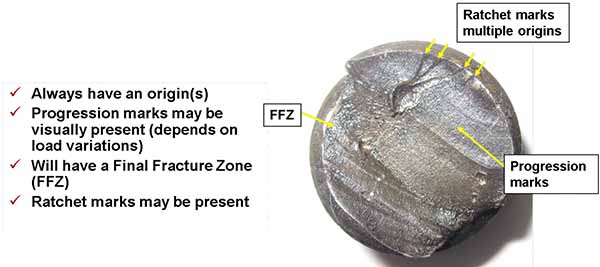

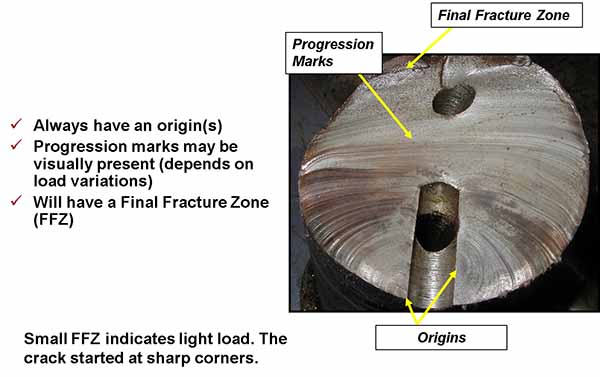

This graphic demonstrates a classic case of fatigue.

Classic Fatigue Pattern

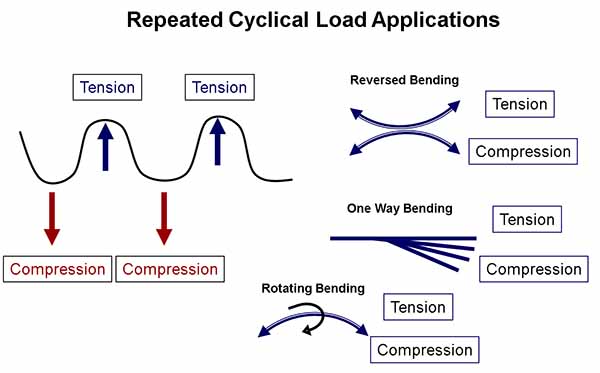

Repeated cyclical loading will surface in a variety of forms. Here are a few such applications:

Cyclical Loading Applications Resulting in Fatigue

Characteristics of Fatigue

Fatigue failures will contain one or more of the following characteristics:

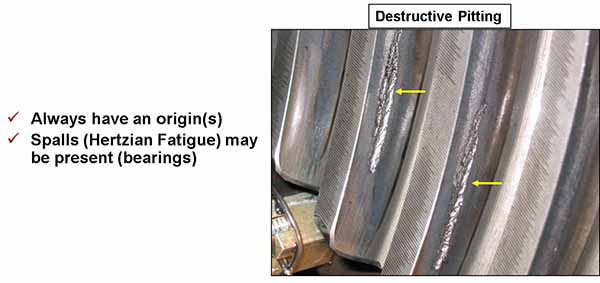

- Always have an origin(s)

- Progression marks may be visually present (depending on load variations)

- Will have a Final Fracture Zone or FFZ (the larger the FFZ, the higher the load)

- Ratchet marks may be present (representing high-stress concentrations [SC])

- Spalls (Hertzian Fatigue) may be present (mainly in bearings)

Now let’s look at some examples from various environments:

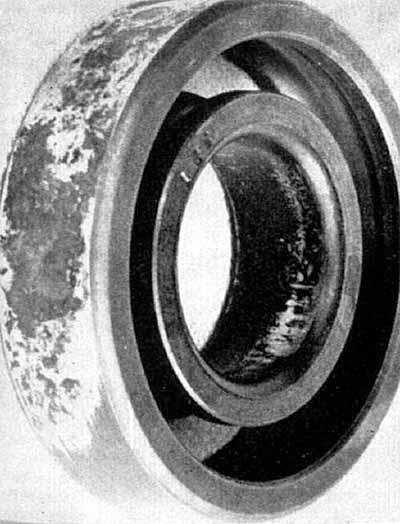

Fatigue – Roller Bearing

Hertzian Fatigue on a Roller Bearing. Rear car wheel bearing experienced excessive thrust loading.

Fatigue – Gear

Spalling on Gear Teeth. The gear is heavily damaged at the addendum or top. The origin is Hertzian (beneath the surface outward). Once the wear is through the area case hardened the failure will be rapid.

Fatigue – Fastener

Fastener Fatigue Example. Manufacturing defect. The fastener has multiple voids in the material.

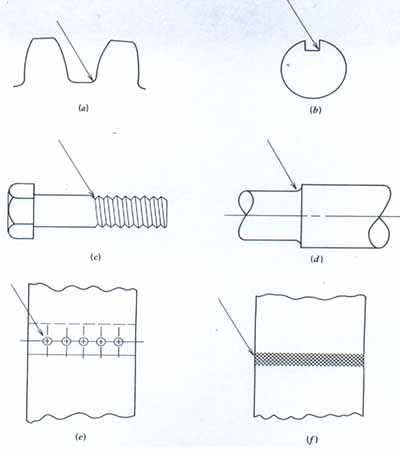

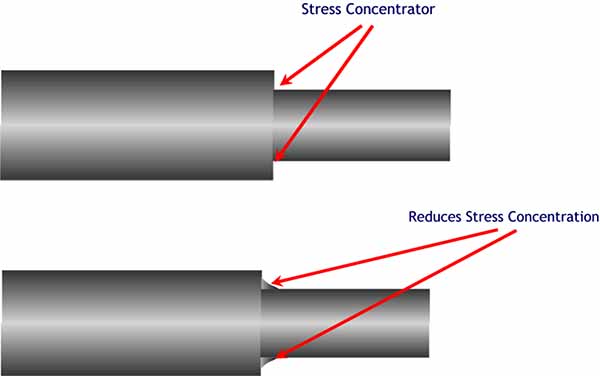

Let’s look at where stress concentrations are most prominent on various components.

Common Types of Stress Concentrations

Stress Concentration (SC) Types. Source: Failure of Materials in Mechanical Design – J. A. Collins

Common Means of Reducing Stress Concentrations (via proper welding techniques)

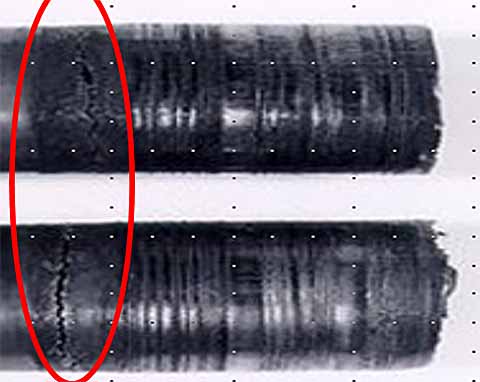

Fatigue – Shaft

Classic Fatigue Fracture Pattern on Shaft

Overload

Material Overload is the failure or fracture of a material with a single load application.

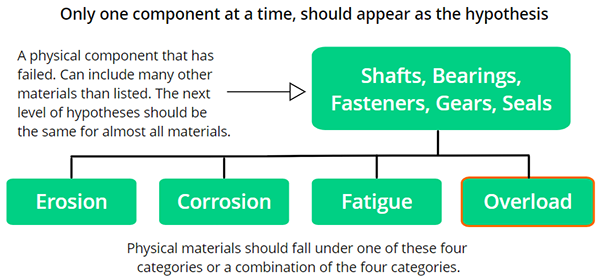

When applying this knowledge to a Root Cause Analysis (RCA), the construction of the Logic Tree (or whatever expression you prefer to use) may look like the following:

How Failure Patterns Work into an RCA

The ‘parent’ node would indicate which component failed (i.e., shaft failure). The ‘child’ nodes would represent the potential hypotheses to the question, ‘How could the shaft have failed?’

The broad and all-inclusive possibilities would be erosion, corrosion, fatigue, and overload. At this stage, our metallurgical analysis will tell us which failure patterns occurred. It could be one or a combination; a trained eye will tell us.

Once we know which pattern(s) is a FACT, we simply keep drilling down and ask, ‘How could the component have been fatigued (example), resulting in the undesirable outcome being experienced?’.

Some reasons materials could be overloaded:

- Wrong material for the application

- Excessive stress or strain

- Flaw in the material

- Sudden increase in load or blockage (process changes)

- Foreign object seized material (gears)

- Foreign object strikes material

- Operating equipment outside of its design capabilities

Component overload examples:

- Shaft Overload

- Fastener Overload

- Hook Overload

- Anchor Overload

- Gear Overload

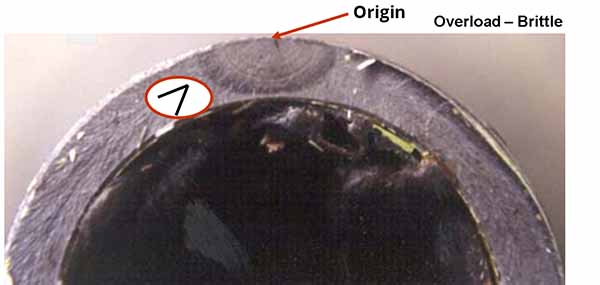

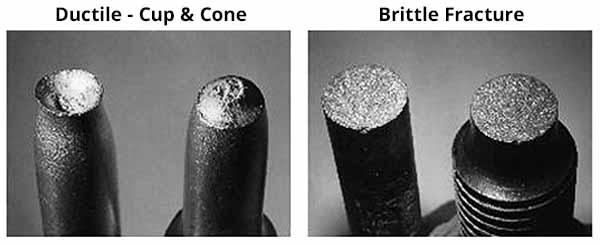

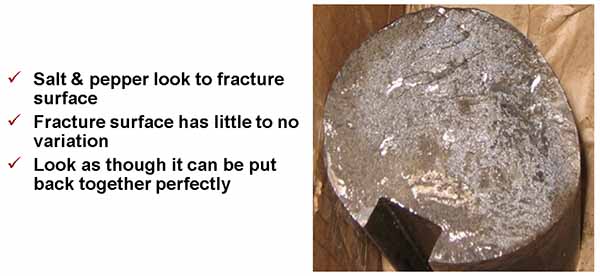

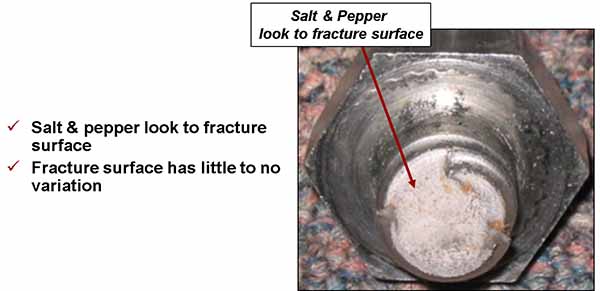

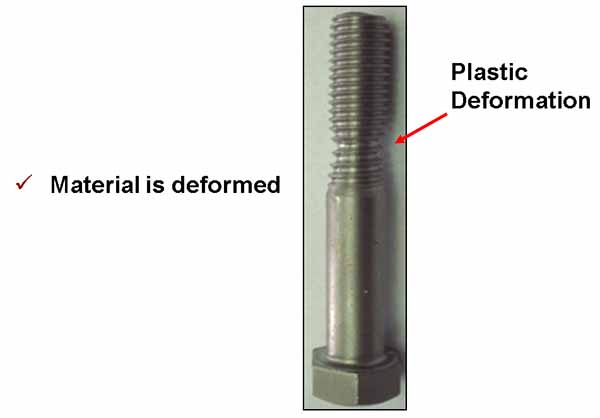

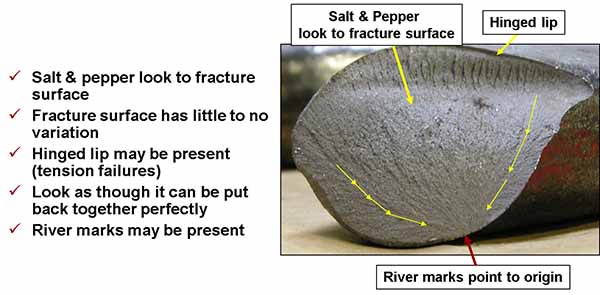

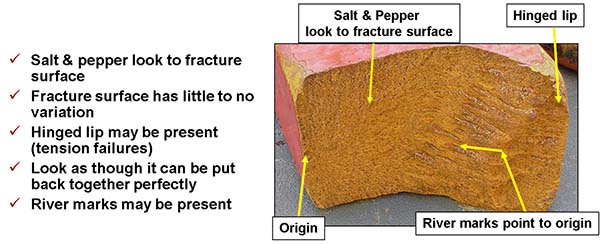

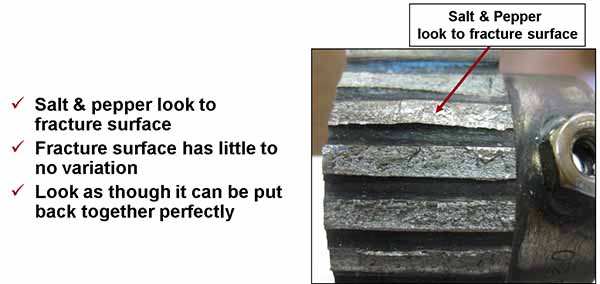

Overload fractures generally fall into two (2) categories: Brittle and Ductile. As you will see from the following examples, Brittle fractures typically exhibit a ‘salt and pepper’ appearance on the fractured surface with a relatively clean break (lack of variation on the fracture surface). Ductile fractures generally exhibit a deformation of the material in some form or fashion.

In Overload cases, the chevron marks will again point towards the origin of the failure.

Graphical Representation of Overload Pattern. You can clearly see this pattern on the failed component.

Chevron Marks Leading Back to Origin

Example of Chevron Marks Pointing to Failure Origin

Ductile vs. Brittle Fracture Surfaces on Fasteners. A clear contrast between Ductile and Brittle failure patterns using fasteners.

Let’s look at some more examples using varied components.

Brittle Overload – Shaft (Gearbox)

Brittle Overload of Gearbox Shaft. Gearbox shaft was overloaded due to improper use of equipment (rocking the unit from forward to reverse to clear a jam).

Ductile Overload – Shaft

Ductile Overload of Gearbox Shaft. Gearbox shaft was overloaded in less than a minute due to an undersized gearbox for the service.

Now, let’s look at fasteners and look for the same patterns to identify whether they are brittle or ductile failures.

Brittle Overload – Fastener

Brittle Overload of Fastener. Bolt was overloaded because the load exceeded the strength of the bolt material.

Another Example of Brittle Overload of Fastener

Ductile Overload – Fastener

Ductile Overload of Fastener. Bolt was overtightened by a mechanic.

Let’s move on to a hook failure and look for similar characteristics of the failed surfaces. Is this a brittle or ductile failure based on its characteristics?

Overload – Hook

Brittle Overload of Hook. A hoist hook was overloaded by side impact loading.

As the caption for this figure states, this is a Brittle Overload. See, it gets easier as we compare and contrast more examples. Let’s try again on an Anchor. We can tell it’s an overload, but which type?

Overload – Anchor

Brittle Overload of Anchor. The anchor was overloaded by side impact loading.

There is no deformation but characteristics of a clean break from being overpowered. In such cases, the opposite sides of the same failed components can often be fitted together to demonstrate they were the same part at one time.

Overload – Gear

Brittle Overload of Gear Teeth

For seasoned investigative veterans, this information will be old news (Investigation 101). However, the more the front-line folks in the field know these basics, the more they can assist these veterans in their investigations. Proper investigations cannot be comprehensive without this physical evidence. So, in the end, we are all helping out each other.